Benchmark 1.5ln low nox boiler, Gf-120 – AERCO BMK 1.5 LN October 2012 User Manual

Page 52

CHAPTER 4

INITIAL START-UP

Page 52 of 166 AERCO International Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 PR1:10/18/12

Benchmark 1.5LN Low NOx Boiler

Installation, Operation and Maintenance Manual

GF-120

OMM-0041 0E

Increase the valve open position to 100% and verify that the gas pressure downstream

11.

of the SSOV remains at 3” W.C. Readjust pressure if necessary.

With the valve position at 100%, insert the combustion analyzer probe into the flue probe

12.

opening and allow enough time for the combustion analyzer to settle.

Compare the measured oxygen level to the oxygen range for the inlet air temperature

13.

shown in Table 4-1. Also, ensure that the carbon monoxide (CO) and nitrogen oxide

(NOx) readings do not exceed the values shown.

Table 4-1: Combustion Oxygen Levels for a

100% Air/Fuel Valve Position

Inlet Air

Temp

Oxygen

%

± 0.2

Carbon

Monoxid

e

NOx

>100°F

4.8 %

<100 ppm

<30 ppm

90°F

5.0 %

<100 ppm

<30 ppm

80°F

5.2 %

<100 ppm

<30 ppm

<70°F

5.3 %

<100 ppm

<30 ppm

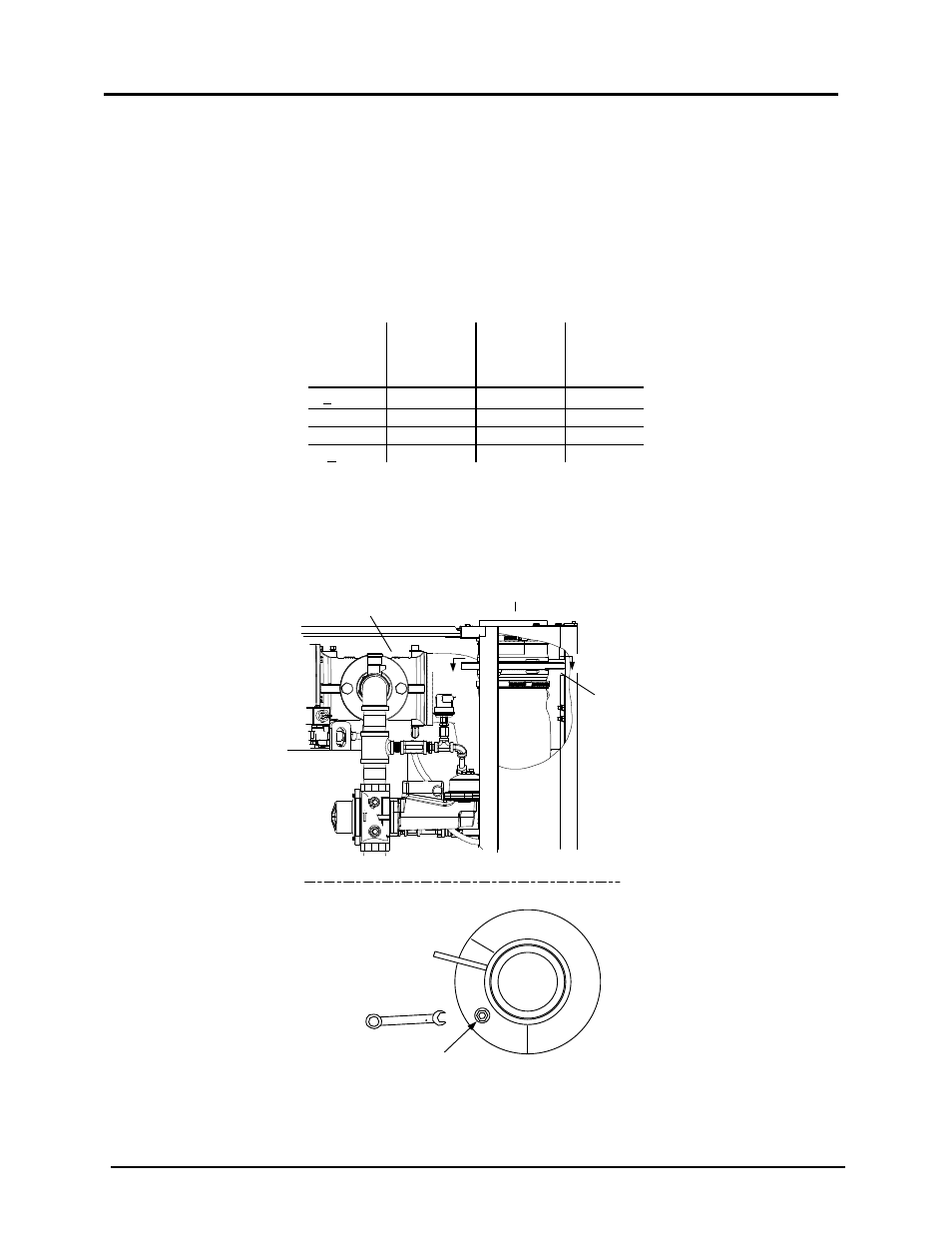

If necessary, adjust the iris air damper shown in Figure 4-5 until the oxygen level is

14.

within the range specified in Table 4-1.

Once the oxygen level is within the specified range at 100%, lower the valve position to

15.

80%.

USE 1/2"

WRENCH TO

INCREASE (CW)

OR DECREASE

(CCW) INLET AIR

IRIS

ADJUSTMENT

VIEW A - A

AIR INLET

IRIS AIR

DAMPER

FRONT

A

A

AIR/FUEL

VALVE

Figure 4-5: Iris Air Damper Location/Adjustment