2 connection and installation, Installing the nozzle/tube, Installing the sj-m series – KEYENCE SJ-M200 User Manual

Page 7: Connecting cables, Connection and installation

6

2-2

Connection and Installation

This section describes how to connect and install the Static Elimination Head and Controller Unit.

Installing the nozzle/tube

Install the nozzle and the tube to the Static Elimination Head by following the procedures below.

It is recommended that this installation be done prior to "Installing the Static

Elimination Head" in the next section. If not, it may become difficult to install the

Static Elimination Head.

■ Installing the nozzle

Attach the nozzle to SJ-M020(G). Attach and tighten

the nozzle mounting fixture to the nozzle to fasten it in place.

■ Installing the tube

An air tube is applicable to SJ-MS3/4 and SJ-ML3/4. Use

an air tube of OP-75350 (PFA tube 500 mm). Static

elimination power varies depending on the length of the

air tube. Check the length carefully before use.

Before using SJ-MS3/4 or SJ-ML3/4 with an air tube mounted, make the "Tube

Installation Setting" in page 8 effective.

CAUTION

Model name

Fastening torque

Between nozzle and nozzle

mounting fixture

2 N·m or less

SJ-MS2/ML2

(between head and adapter)

2–3 N·m or less

SJ-MS3/ML3

(between head and adapter)

7 N·m or less

SJ-MS4/ML4

(between head and adapter)

7 N·m or less

SJ-MS1/ML1

(between resin head and

adapter)

Fasten manually until it stops.

Then use a tool such as

wrench and rotate approx. 2 or

3 times to fasten more. Fix in

your desired direction. If you

fasten a screw too tightly, a

screw section may result in

breakage. Insufficient

fastening may result in

looseness or leakage.

Nozzle mounting fixture

CAUTION

2-2

Connection and Installation

Installing the SJ-M Series

Install the SJ-M Series at locations where static electricity is generated or is likely to be generated.

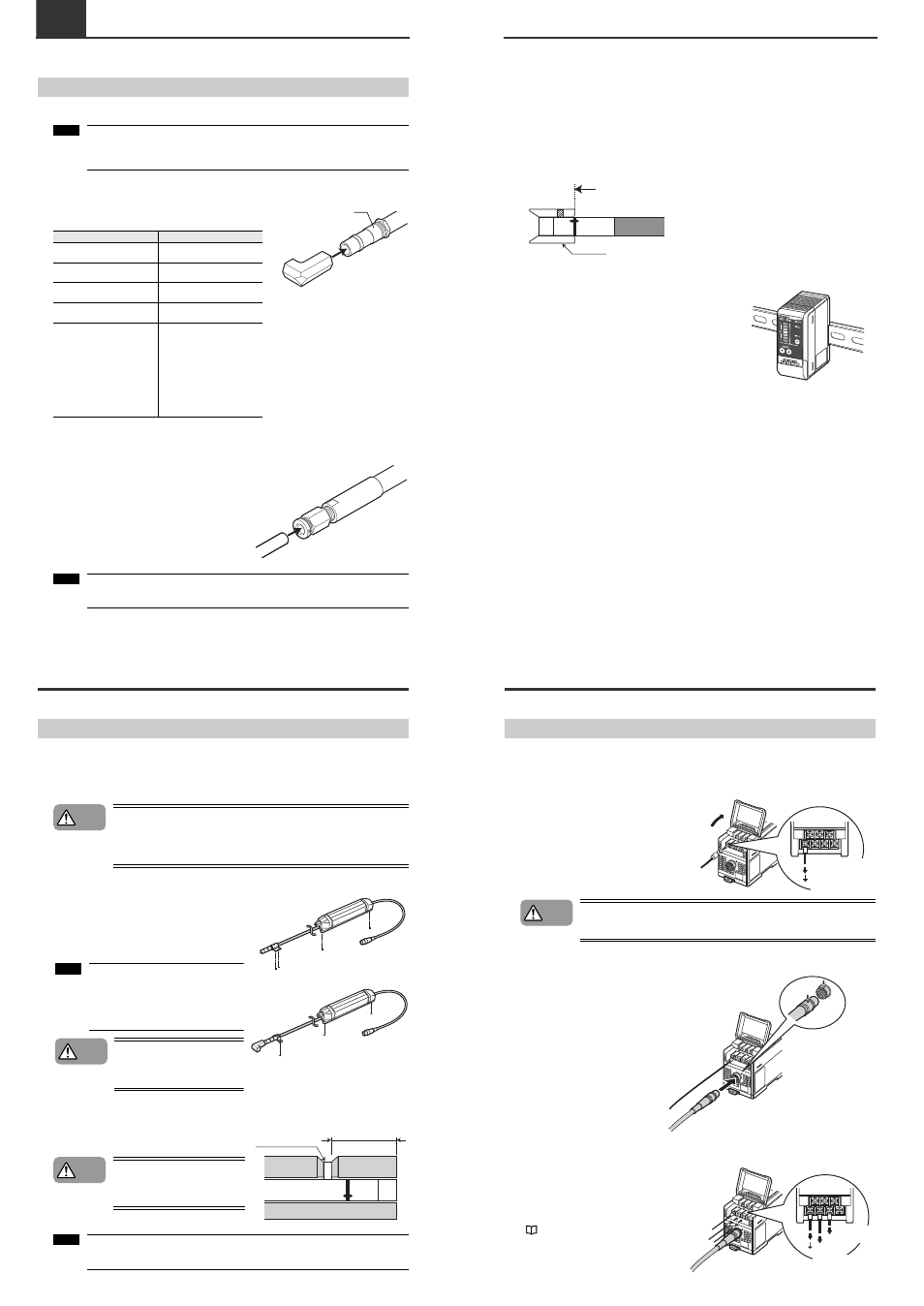

■ Installing the Static Elimination Head

There are two ways of installing the Static Elimination Head, with or without the mounting fixtures.

When installing the SJ-M Series, observe the minimum bending radius of all

provided cables. Also, do not install the SJ-M Series with the cables deformed

by staples or other objects. Doing so might cause the SJ-M Series to

malfunction.

●

When the mounting fixture is used:

When installing the SJ-M010/020(G), prepare tapped

mounting holes, and install the SJ-M010/020(G) with

M3 screws at a tightening torque of 1 Nm or less (M4

screws: 1 Nm or less).

The M3 screws and bundling band for fastening the

mounting fixture must be prepared separately.

●

When the mounting fixture is not used:

When mounting the SJ-M010/020(G) using the M3 set

screws, tighten at a torque of 0.1 Nm or less.

Install within the allowable mounting fixture range indicated in the external

dimension drawings. Otherwise, static may not be eliminated properly.

CAUTION

M3 tap

M4 tap

M3 tap

M4 tap

•SJ-M010

•SJ-M020 (G)

Install the mounting fixture within the

allowable mounting fixture range

indicated in the external dimension

drawings. Otherwise, static may not be

eliminated properly.

Make a space of 30 mm or more

around the drive unit. Otherwise,

the unit may be damaged.

Important

CAUTION

M3 set screw (flat)

28 mm or more

Limit the tightening torque to

0.1 Nm. Exceeding this torque

might damage the set screws.

CAUTION

Important

2-2

Connection and Installation

■ Installing the discharge prevention cap (option)

An optional discharge prevention cap is available to prevent the risk of accidentally touching the Static

Elimination Head and causing discharge during maintenance work, for example. Use this cap if

necessary.

■ Installing the cap

Install the discharge prevention cap as shown in the following figures, and fasten in place using the set

screws (provided).

(Tightening torque: SJ-M010/020(G): 0.04 Nm or less)

■ Installing the Controller unit

Install and fasten in place

so that the end surface of

the cap is at this position.

OP-75354

●

SJ-M010/020(G) (cross-section view)

Mount the Controller Unit on the DIN rail.

2-2

Connection and Installation

Connecting Cables

When you have finished installing the Static Elimination Head, connect the earth lead, Static

Elimination Head connector cable and power supply.

■ Connecting the earth lead

Open the terminal plate cover on the Controller

Unit, and connect the earth lead to the GND

connection terminal.

Be sure to connect a Class D earth (maximum

resistance of 100 Ohms).

To prevent electric shock and to ensure accurate static elimination, be sure to

connect a Class D earth (maximum resistance of 100 Ohms).

■ Connecting the cable

Connect the Static Elimination Head

connector cable to the Controller Unit.

Connect this cable with the power

turned OFF.

When installing the Controller Unit

away from the Static Elimination

Head, use the optional extension

cable (SJ-C3).

■ Connecting the power supply

Connect the power supply according to either

of the following methods.

24 VDC power supply

Connect a 24 VDC output power supply

having sufficient power capacity margin to the

power terminals (terminals (5) and (6))

"Controller Unit (I/O terminal section)" (page

3)

Be sure to connect

a Class D earth

(maximum resistance

of 100 Ohms).

WARNING

Match and connect

the end of the connector

cable to the inlet on the

Controller Unit.

To 24 VDC

power supply

To 24 VDC

power supply