Installation precautions – KEYENCE SJ-M200 User Manual

Page 6

5

2-1

Before Installation

Model No. SJ-M020+SJ-MS3/ML3 (500 mm)

Air flow rate 140 Nl/min (pressure

0.3 MPa)

Air flow rate 230 Nl/min (pressure

0.5 MPa)

Model No. SJ-M020+SJ-MS4/ML4 (500 mm)

Air flow rate 145 Nl/min (pressure

0.3 MPa)

Air flow rate 240 Nl/min (pressure

0.5 MPa)

200 150 100 50

0

50 100 150 200

mm

mm

0

200

400

600

100

300

500

800

1000

700

900

3sec

5sec

7sec

200 150 100 50

0

50 100 150 200

mm

mm

0

200

400

600

100

300

500

800

1000

700

900

1100

1300

1500

1200

1400

5sec

7sec

3sec

8sec

2sec

200 150 100 50

0

50 100 150 200

mm

mm

0

200

400

600

100

300

500

800

1000

700

900

7sec

10sec

13sec

200 150 100 50

0

50 100 150 200

mm

mm

0

200

400

600

100

300

500

800

1000

700

900

1100

1300

1500

1200

1400

5sec

10sec

15sec

2-1

Before Installation

Model No. SJ-M020+SJ-ML

Air flow rate 20 Nl/min

(pressure 0.02 MPa)

Air flow rate 60 Nl/min

(pressure 0.1 MPa)

Air flow rate 250 Nl/min (pressure

0.5 MPa)

200 150 100 50

0

50 100 150 200

mm

mm

0

200

400

600

100

300

500

3sec

10sec

15sec

20sec

200 150 100 50

0

50 100 150 200

mm

mm

0

200

400

600

100

300

500

800

1000

700

900

1sec

5sec

10sec

2sec

200 150 100 50

0

50 100 150 200

mm

mm

0

200

400

600

100

300

500

800

1000

700

900

1100

1300

1500

1200

1400

0.5sec

1sec

2sec

2-1

Before Installation

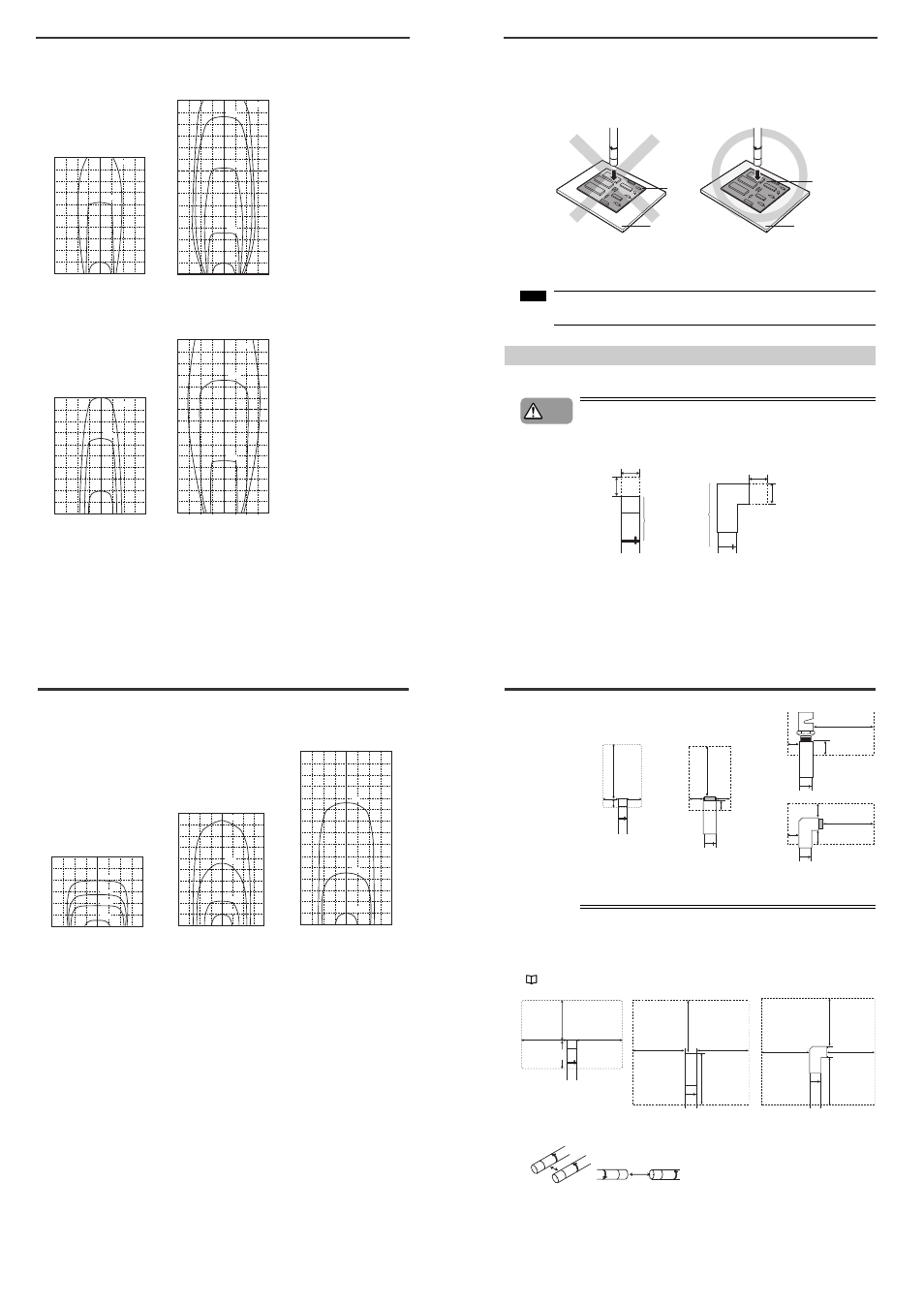

■ Appropriate static elimination method

Pay attention to the following points to ensure that static elimination is performed appropriately.

Static elimination cannot be performed accurately at locations where the target object is

touching a metallic body (earthed body).

Eliminate static from the target object at locations where it is not directly touching metallic bodied

(earthed body).

Static will be eliminated from only the surface of the insulated body (board, etc.) that is facing

the Static Elimination Head.

When eliminating static from both sides of a target object, install two SJ-M Series as one SJ-M Series

must be installed on either side of the target object.

Install the Static Elimination Head so that it can be easily accessed, for example, for

replacement of parts and cleaning.

Installation Precautions

■ Installation site

Install the tip of the SJ-M010/020(G) paying attention to the following point.

• Install the Static Elimination Head away from the wall or surrounding

objects.

• Protect the area around the tip of the Static Elimination Head with silicon,

fluoro-resin or other highly ozone-resistant resin. Ozone that is generated may

cause the metal or resin on the SJ-M010/020(G) to rust, corrode or deteriorate.

Insulating mat

Metal

Board

Board

Note

CAUTION

The section marked by "*" must not touch the conductor (earthed body).

The adapter nozzle must not touch the conductor (earthed body).

23mm*

10 mm or more

10 mm

or more

10 mm or more

10 mm

or more

Requires 10 mm or more away

from the air outlet

*

●

SJ-M010/020(G)

2-1

Before Installation

• Do not install the Static Elimination Head at locations where moving parts of

other equipment and machinery may place stress on the cable. Doing so

might cause the SJ-M010/020(G) Series to malfunction.

■ Interference

The Static Elimination Head may not function properly if there is a conductor (earthed body) located

nearby or if two or more units are used close to each other. In such an installation, refer to the figure

below and maintain the indicated distance between the conductor (earthed body). If a conductor (earthed

body) is located inside the distances indicated below, adjust using the ion balance manual setup.

"Ion Balance Adjustment Function" (page 8)

When two SJ-M Series units are used, refer to the figures below, and install the units so that the

following distances are maintained between the two Static Elimination Heads.

200 mm

or more

20 mm

or more

10 mm

or more

20 mm

or more

20 mm or more

10 mm

or more

200 mm or more

10 mm

or more

20 mm or more

20 mm or more

200 mm or more

When SJ-MS2

is used

When SJ-ML1

is used

When SJ-MS1

is used

200 mm

or more

20 mm

or more

10 mm

or more

20 mm

or more

●

SJ-M010/020 (G)

60 mm or more

away from the

nozzle or air outlet

60 mm or more

60 mm or more

60 mm

or more

60 mm or

more away

from the

nozzle or

air outlet

60 mm or more

60 mm or more

60 mm

or more

●

SJ-M010/020 (G)

60mm or more

60mm

or more

60mm

or more

35mm or more

●

SJ-MS*

●

SJ-ML*

60 mm or more

60 mm or more