2 performing maintenance on the electrode probe, Performing maintenance on the electrode probe, 1 timing charts – KEYENCE SJ-M200 User Manual

Page 12: 2 specifications, Timing charts, Specifications, How to clean the electrode probe, How to replace the electrode probe, Ion generation control timing chart, Input response timing chart

11

4-2

Performing Maintenance on the Electrode probe

When the SJ-M Series is used for a long period of time, the electrode probe becomes dirty due to the

adhesion of dust and dirt.

If the electrode probe is used in a dirty or dusty state, static elimination performance can no longer be

fully demonstrated, resulting in accidents or malfunction. Be sure to periodically perform maintenance

on the electrode probe.

Performing Maintenance on the Electrode probe

• Before removing the Electrode Unit, turn the SJ-M Series OFF.

• Do not directly touch the electrode probe with your hands. Doing so may

cause personal injury. Pay attention to this when performing maintenance

on the electrode probe.

■ How to clean the electrode probe

Clean the electrode probe gently with a cotton wool bud

moistened with alcohol.

■ How to replace the electrode probe

Note: If cleaning the electrode probe does not improve static elimination performance, or the ion level

alarm indicator frequently lights, a probable cause is that the electrode probe has reached the end of its

service life.

Electrode replacement units for SJ-M020 (OP-51607) and for SJ-M020G (OP-75351) are available in

options.

●

How to remove and install the electrode probe

The electrode probe can be removed by holding the tip of

the electrode probe and turning counterclockwise, and

installed by turning clockwise.

WARNING

Rotate while

holding this area.

5-1

Timing Charts

This section provides timing charts for SJ-M Series.

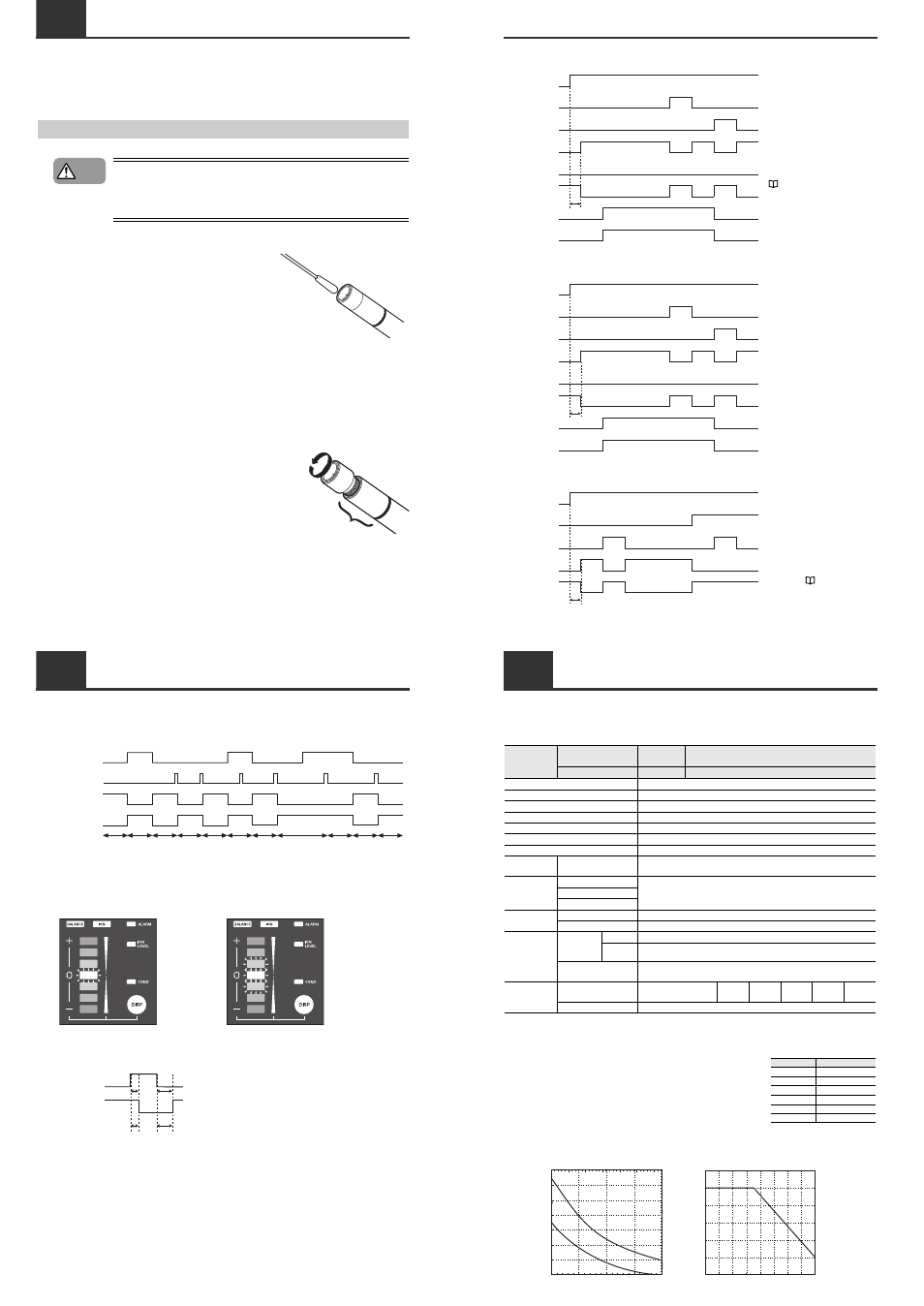

■ Ion generation control timing chart

Indicator states when static elimination is OFF

Normal static elimination OFF

The center LED of the ion monitor blinks (red).

■ Input response timing chart

Normally ON Normally OFF Normally ON Forced OFF Normally ON Normally OFF Normally ON

Static elimination

stop input (terminal)

ON

OFF

Static elimination

stop input (controller)

ON

OFF

Ion emission state

Unit indicator

Emitting

No emissions

Alarm output

ON

OFF

Forced OFF

Forced OFF

Normally ON

Normally OFF

Max. 15 ms

Max. 1 s

Static elimination

stop input (unit)

ON

OFF

Ion emission

state

Emitting

No emissions

Normal static elimination OFF

The three center LEDs of the ion monitor

blink (red).

5-1

Timing Charts

■ Ion level alarm output timing chart

■ Condition alarm output timing chart

■ Alarm output timing chart

Power

ON

OFF

Static elimination

stop input (terminal)

ON

OFF

Static elimination

stop input (controller)

ON

OFF

Alarm indicator

Blinking

OFF

Alarm output (N.C.)

ON

OFF

Ion emission

Emitting

No emissions

Ion level indicator

Max. 10s

Blinking

OFF

Ion level alarm

output (N.O.)

ON

OFF

When the ion level alarm is output,

removing the cause of the alarm can

restore the normal state. One way of

restoring the normal state is to

perform maintenance on the electrode

probe.

For details on electrode probe

maintenance, see "Performing

Maintenance on the Electrode probe"

(

page 11).

Power

ON

OFF

Alarm indicator

Blinking

OFF

Alarm output (N.C.)

ON

OFF

Ion emission

Emitting

No emissions

Condition indicator

Blinking

OFF

Condition alarm

output (N.O.)

ON

OFF

Max. 10s

Static elimination

stop input (terminal)

ON

OFF

Static elimination

stop input (controller)

ON

OFF

When the condition alarm is output,

removing the cause of the alarm can

restore the normal state. One way of

restoring the normal state is to

improve the installation environment.

Power

ON

OFF

Static elimination

stop input

ON

OFF

Alarm indicator

Blinking

OFF

Alarm output (N.C.)

ON

OFF

Ion emission

Emitting

No emissions

Max. 10 s

When the alarm is output, the normal

state can be restored by performing

one of the two available restore

methods depending on the cause of

alarm output.

For details on how to restore the

normal state, see “During an alarm

(levels 1, 2)” (

page 14).

5-2

Specifications

This section provides the specifications of the SJ-M100/200 Series.

■ Static Elimination Head/Controller Unit

*1:

Values obtained at an installation distance of 50 mm and air flow rate of 60 Nl/min (ambient operating temperature +20

to +30°C, ambient operating humidity 40 to 60% RH) (without nozzle)

*2:

Values obtained at an installation distance of 50 mm and air flow rate of 20 Nl/min (ambient operating temperature +20

to +30°C, ambient operating humidity 40 to 60% RH) (without nozzle)

*3:

Inquire for derating of humidity/pressure in environments exceed +35°C. Use

clean or dry air at a temperature of -20°C or less as the supply fluid. And the

air pressure is different by a model of a nozzle at least (the right chart).

*4:

During regular use, supply air at a supply fluid temperature of +40°C or less.

*5:

These values are for the High-pressure Cable Unit only. The ambient

operating temperature is 0 to +40°C at other parts.

*6:

When the ambient temperature exceeds +40°C, perform derating according to

the following figures.

*7:

As for SJ-M010, a combination with SJ-M200 is possible, too.

●

Temperature/humidity derating graph

Model

Static Elimination Head SJ-M010

*7

SJ-M020/SJ-M020 (1.2M)/SJ-M020 (0.6M)/

SJ-M020G/SJ-M020G (1.2M)/SJ-M020G (0.6M)

Controller Unit

SJ-M100

SJ-M200

Voltage application method

Pulse AC

Applied voltage

±5.5 kV

Rated output voltage

±6 kV

Ion balance control method

I.C.C. method

Static elimination time

0.5 sec. max.

*1

Ion balance

±15 V or less

*2

Max. air pressure

0.001 to 0.5 MPa

*3

Control input

Static elimination stop

input

No-voltage input

Control output

Alarm output

NPN open collector

100 mA 40 V or less

Ion level alarm output

Condition alarm output

Rating

Power voltage

24 VDC ±10%

Current consumption

450 mA max.

Environmental

resistance

Operating

ambient

temperature

Head

0 to +80°C

*4, 5, 6

Controller

0 to +40°C

Operating ambient

humidity

35 to 65%RH

Weight

Static Elimination Head

Approx. 600 g

Approx.

540 g

Approx.

480 g

Approx.

600 g

Approx.

540 g

Approx.

480 g

Controller Unit

Approx. 300 g

Nozzle

Min. air pressure

without nozzle

0.001MPa (2.6Nl/min)

SJ-ML

0.02MPa (20Nl/min)

SJ-MS/ML1

0.03MPa (20Nl/min)

SJ-MS/ML2

0.02MPa (20Nl/min)

SJ-MS/ML3

0.08MPa (50Nl/min)

SJ-MS/ML4

0.08MPa (50Nl/min)

0.6

0.5

0.4

0.3

0.2

0.1

0

0

10

20 30

40 50

60

70

80

70

60

50

40

30

20

10

40

50

60

70

80

0

Am

b

ient

o

per

a

tin

g

h

u

midi

ty (% RH)

Ambient operating temperature (°C)

Max. oper

at

ing pre

ss

u

re

(M

P

a

)

Ambient operating temperature (°C)