Holtgreven Truck Scale Resources User Manual

Page 28

PT300 Users manual

Rev G, Feb 2011

Page 28 of 44

1. Position the corner fixture with rubber pad on the scale position #1. Apply 2500 lbs to the

loading block. Annotate the reading.

2. Repeat for the #2 position.

3. If all readings are within 5 pounds and the previous calibration passed all of the readings

continue with the rest of the calibration verification. If the corner check fails go to the corner

adjust calibration procedure.

Scale Span Calibration

Tools required:

•

Calibration force generator; press or deadweights. This calibration source must cover the

range of 10% to 100% of nominal capacity with an accuracy of 0.25% of reading or better.

PT300

•

100027 - 8" (

±

0.25") x 8" (

±

0.25") x 1.75" (minimum) aluminum loading block.

•

100028-A - 8" (

±

0.25") x 8" (

±

0.25") x 0.5" (

±

0.125") rubber loading scale. (40 to 70 Shore A

rating)

PT300DW

•

100029

- 12" (

±

0.25") x 12" (

±

0.25") x 1.75" (minimum) aluminum loading block.

•

100030-A

- 12" (

±

0.25") x 12" (

±

0.25") x 0.5" (

±

0.125") rubber loading scale. (40 to 70 Shore

A rating)

4. Bring the scales to the calibration site. If there is more than 5

°

F difference in temperature

between the scale temperature and the calibration site allow the scales to reach room

temperature.

5. Place scale on calibration fixture. Turn scale on. Wait 3 minutes for warm-up.

6. Apply test forces every 10% of the scales capacity and verify that the reading falls within 1% of

the applied force or 1 display division whichever is greater as shown in the sample table below.

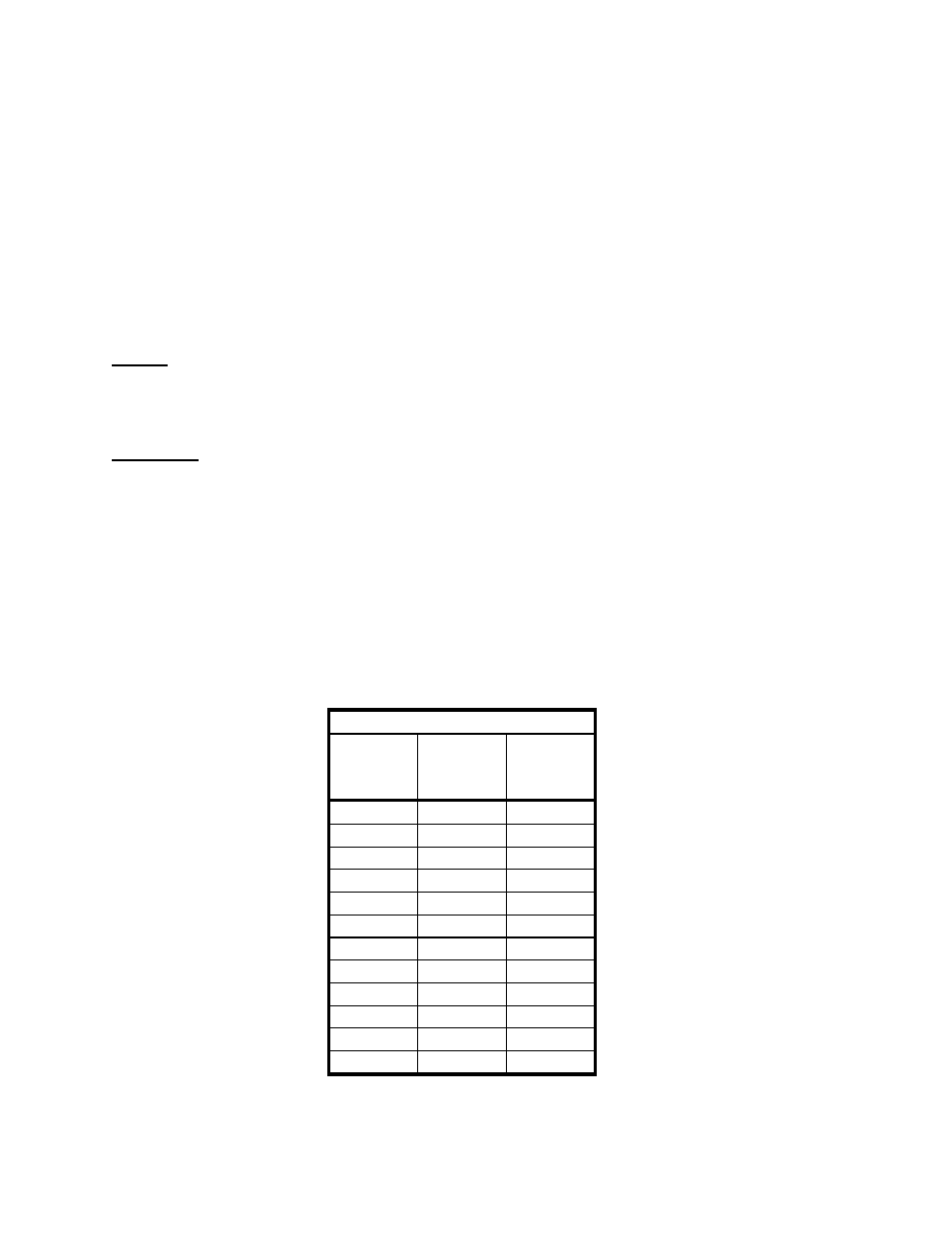

20K Capacity

Test

force

(lb)

Lower

limit

(lb)

Upper

Limit

(lb)

0

0

0

2000

1980

2020

4000

3960

4040

6000

5940

6060

8000

7920

8080

10000

9900

10100

12000

11880

12120

14000

13860

14140

16000

15840

16160

18000

17820

18180

20000

19800

20200

0

-20

20

7. If any value is out of acceptable limits proceed to the adjust calibration procedure.

8. If all values are within acceptable limits unit passes calibration verification.