Checkline Series-5 User Manual

Page 3

Series 5 Digital Force Gauges

User’s Guide

2

1 OVERVIEW

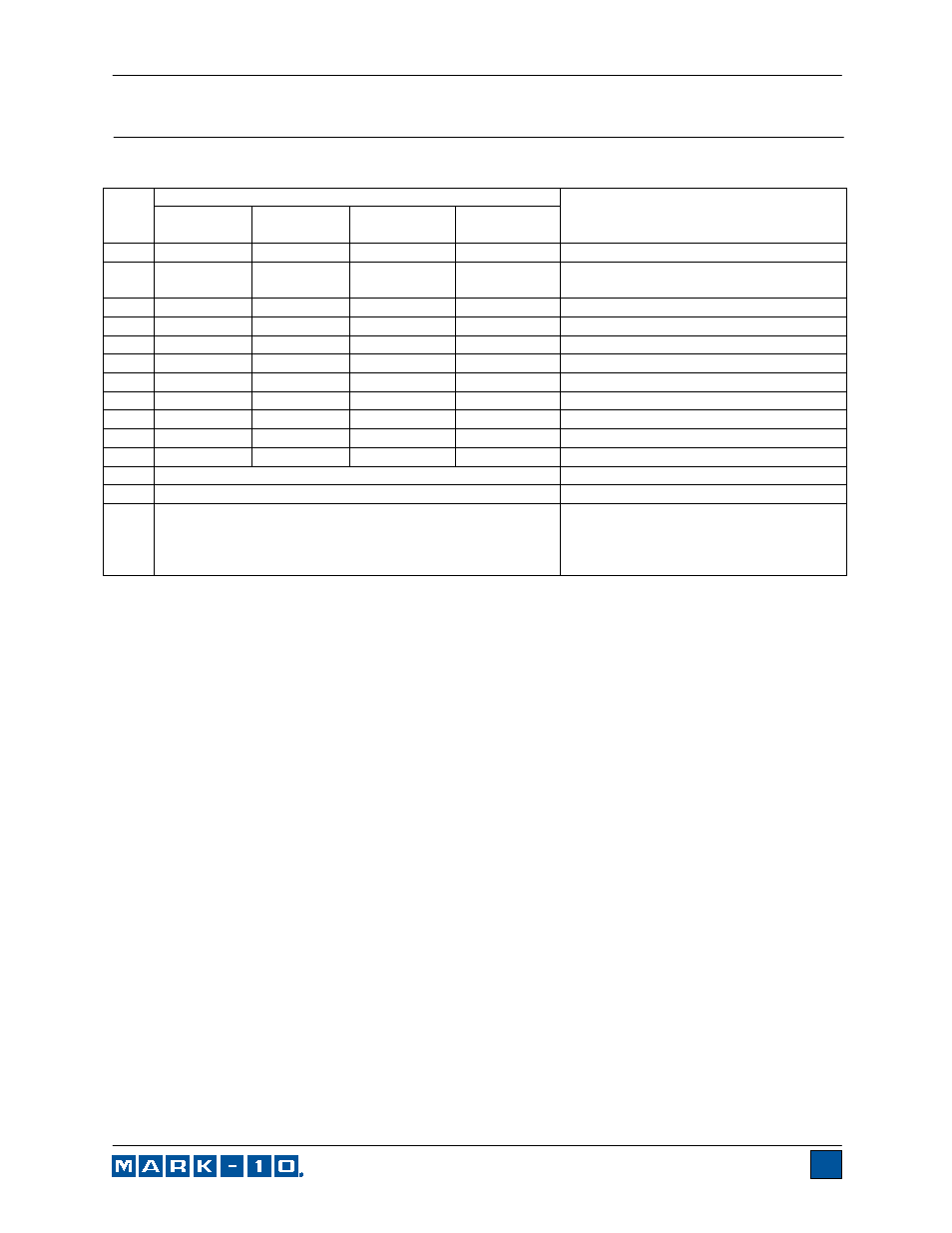

1.1 List of included items

Qty.

Part No.

Description

M5-012 –

M5-20

M5-50 –

M5-100

M5-200 –

M5-500

M5-1000

1

12-1049 12-1049 12-1049 12-1049 Carrying

Case

1

08-1022

08-1022

08-1022

08-1022

AC adapter body with US, EU, or UK

prong

1

08-1026

08-1026

08-1026

08-1026

Battery (inside the gauge)

1

G1024 G1024 G1031 G1031 Extension

rod

1

G1026 G1026 G1033 G1033 Cone

1

G1025 G1025 G1032 G1032 Chisel

1

G1027 G1027 G1034 G1034 V-groove

1

G1029 G1029 G1036 G1036 Flat

1

G1028 G1038 G1035 G1042 Hook

1

-

G1039 G1037 G1037 Coupling

1

- - - G1041

Thread

adapter

1

-

Certificate of calibration

1 09-1165

USB

cable

1

-

Resource CD (USB driver, user’s

guides, MESUR Lite software,

MESURgauge DEMO software, User’s

Guide)

1.2 Safety / Proper Usage

Caution!

Note the force gauge’s capacity before use and ensure that the capacity is not exceeded.

Producing a force greater than 150% of the gauge’s capacity can damage the internal load cell. An

overload can occur whether the gauge is powered on or off.

Typical materials able to be tested include many manufactured items, such as springs, electronic

components, fasteners, caps, films, mechanical assemblies, and many others. Items that should not be

used with the gauge include potentially flammable substances or products, items that can shatter in an

unsafe manner, and any other components that can present an exceedingly hazardous situation when

acted upon by a force.

The following safety checks and procedures should be performed before and during operation:

1. Never operate the gauge if there is any visible damage to the AC adapter or the gauge itself.

2. Ensure that the gauge is kept away from water or any other electrically conductive liquids at all

times.

3. The gauge should be serviced by a trained technician only. AC power must be disconnected and

the gauge must be powered off before the housing is opened.

4. Always consider the characteristics of the sample being tested before initiating a test. A risk

assessment should be carried out beforehand to ensure that all safety measures have been

addressed and implemented.

5. Wear eye and face protection when testing, especially when testing brittle samples that have the

potential to shatter under force. Be aware of the dangers posed by potential energy that can