Important, Low voltage electrical connections - peak control, Line voltage wiring diagram figure 10 – Steffes 7140 User Manual

Page 18: Nc p rp com ap no, Installation, 07 comfort plus commercial hydronic, Loop pump primary, 7120 line voltage

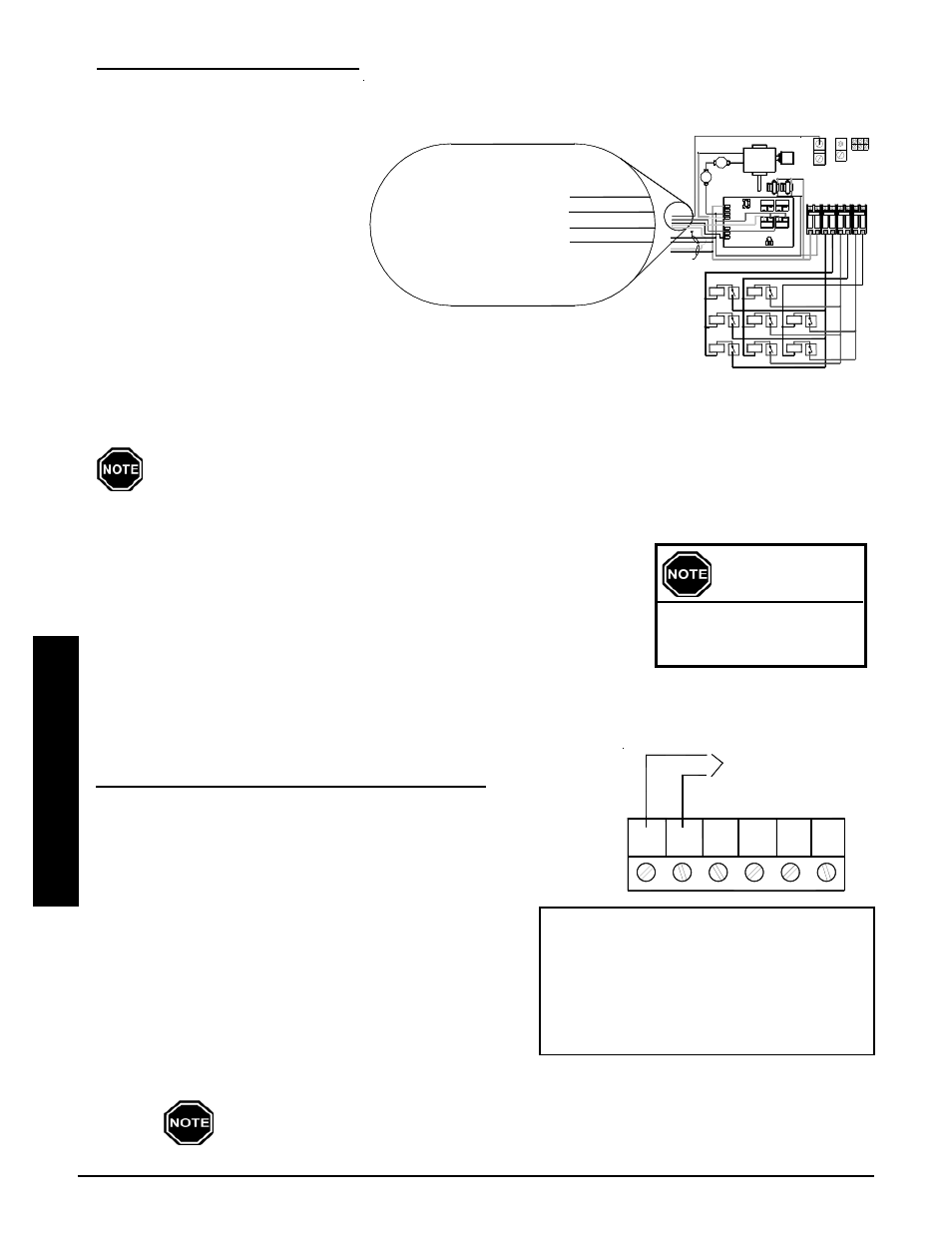

6-Position Low Voltage Terminal Block Coding

RP = Peak Control Input Common

P = Peak Control Input

AP = Anticipated Peak (Pre-Peak) Control Input

COM = Peak Control Output Common

NC = Peak Control Output (Normally Closed)

NO = Peak Control Output (Normally Open)

LOW VOLTAGE ELECTRICAL CONNECTIONS - PEAK CONTROL

Steffes ETS heating equipment may be controlled by the Power Company via a

peak control signal. This signal can be sent to the equipment using a Steffes

Power Line Carrier control system, low voltage wiring, a Steffes Time Clock

Module, or line voltage control. In applications utilizing automatic charge control,

outdoor temperature information is required and can be received via an outdoor

sensor or power line carrier control system.

The Comfort Plus Commercial Hydronic system is factory configured for

low voltage peak control and is set to charge when the utility peak control

switch closes. Refer to the Configuration Menu (Pages 3.14-3.15) for

information on configuring the system for the application.

LOW VOLTAGE (HARD WIRED) PEAK CONTROL

If using the low voltage peak control option, the Comfort Plus Commercial

Hydronic is direct wired to the power company's peak control switch. Field

connections from the peak control switch are made to the low voltage

terminal block through a low voltage knockout located on the left side of the

electrical panel.

Step 1 Route a low voltage circuit from the power

companys load control or peak signaling device to

the six (6) position low voltage terminal block inside

the electrical compartment of the Comfort Plus

Commercial Hydronic system through one of its low

voltage wire knockouts.

Step 2 Connect the field wiring to positions "RP" and "P" on

the six (6) position low voltage terminal block. (See Figure 11.)

To use the Comfort Plus to control other loads, refer to Auxiliary Load Control (Page

3.13).

Installation

Installation

n

3.07

Comfort Plus Commercial Hydronic

Low voltage wires

MUST never enter any

line voltage enclosure.

IMPORTANT

JUNCTION BOX INSTALLATION

Step 1 Attach the factory supplied

junction box to the left side

of the Comfort Plus Hy-

dronic Commercial system

as shown in Figure 16

(Page 3.12).

Step 2 Make connections to the

primary loop pump and air

handler pump inside this

junction box. The red and

white wires connect to the

primary loop pump and the

black and white wires

connect to the air handler

pump. (See Figure 10.) The maximum connected amperage on either of these circuits is 1.2 amps.

Step 3 Attach the junction box cover using the screws provided.

PEAK CONTROL

TERMINAL CONNECTIONS

FIGURE 11

NC

P

RP

COM

AP

NO

To Dry Contact Peak

Control Switch

LINE VOLTAGE WIRING DIAGRAM

FIGURE 10

These wires are located in the lower left

corner of the electrical compartment.

WHITE/BLACK

RED

BLACK

WHITE

OR

#2

Element

#1

Element

#3

Element

#5

#8

Element

Element

Element

#4

#7

Element

#6

Element

15A

C

IRC

UI

T

CONT

R

O

L

S

BL

O

W

ERS/

CI

RC

U

IT

#

2

CI

RC

U

IT

#

1

CI

RC

U

IT

#

3

RE

D

BL

A

C

K

BL

U

E

60A

CH

AR

G

E

CH

AR

G

E

60A

CH

AR

G

E

60A

7120 Line Voltage

Use copper or aluminum conductors rated at

Wiring Diagram 208/240 Volt

75° C or higher for field connections of this device.

BLACK

WHITE

EXCHANGER

LIMITS

RESET

225 °

AUTO

MANUAL

N.C.

250 °

TRANSFORMERS

CORE BLOWER

HIGH

COM.

240v / 24v

Cap.

4uf

To Optional Static

Heat Recovery System

BLACK/YELLOW

BLUE/WHITE

ORANGE

BLACK

RED

DAMPER

To Optional Air Handler

5 Amp

5 Amp

RESISTER

RESISTOR

BASE IO BOARD

BL

AC

K/

Y

E

L

L

O

W

ORANGE

BLACK

RED

BLUE

N.C.

RESET

BLOWER

L2 120

L2 240

COM

COM

1/4 Amp

1/4 Amp

NO

NO

COM

COM

SHRU

NO

NO

NO

NO

COM

COM

NO

NO

COM

COM

NEUTRAL LUG

CONTROL CIRCUIT

GROUND

LUGS

L1

BLUE/BLACK

Red & White To Primary

Loop Pump (Max 1.2 AMPS)

Black & White To Air Handler

Pump (Max 1.2 AMPS)

WHITE/BLACK

WHITE

OR

LOOP PUMP

PRIMARY

ORANGE

If utilizing the optional air handler, the orange wire can be used with the white wire to power

a secondary pump for hydronic zones.