Carrier 19XR,XRV Hermetic Centrifugal Liquid Chillers User Manual

Page 79

79

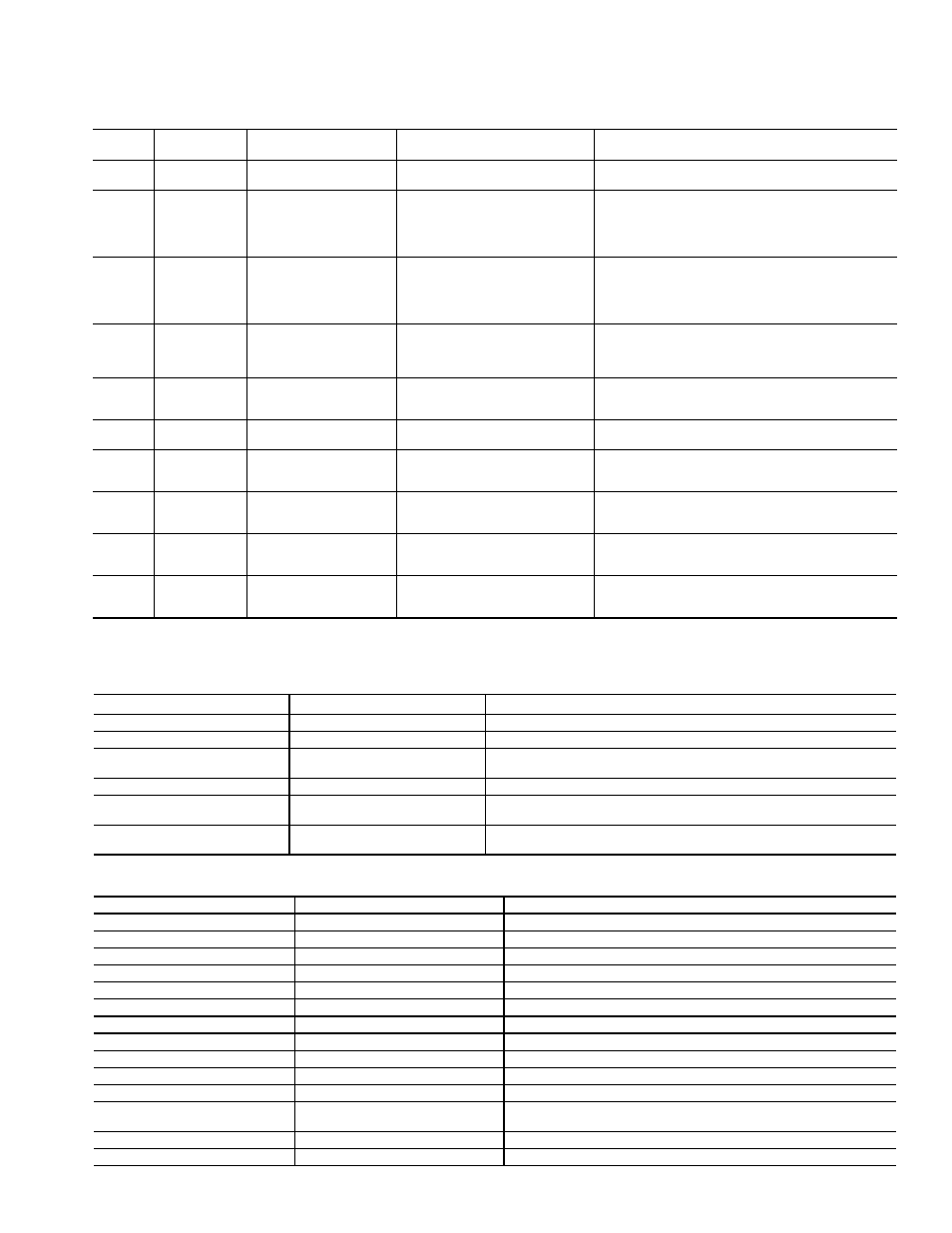

Table 11 — CVC/ICVC Primary and Secondary Messages and

Custom Alarm/Alert Messages with Troubleshooting Guides (cont)

D. PRE-START ALERTS: These alerts only delay start-up. When alert is corrected, the start-up will continue. No reset is necessary.

*[LIMIT] is shown on the CVC/ICVC as temperature, pressure, voltage, etc., predefined or selected by the operator as an override or an alert.

[VALUE] is the actual pressure, temperature, voltage, etc., at which the control tripped.

E. START-UP IN PROGRESS

F. NORMAL RUN

STATE

PRIMARY

MESSAGE

SECONDARY

MESSAGE

ALARM MESSAGE

PRIMARY CAUSE

ADDITIONAL CAUSE/REMEDY

100

PRESTART

ALERT

STARTS LIMIT

EXCEEDED

100->Excessive compressor

starts (8 in 12 hours)

Depress the RESET softkey if additional start is

required. Reassess start-up requirements.

101

PRESTART

ALERT

HIGH BEARING

TEMPERATURE

101->Comp Thrust Bearing

Temp [VALUE] exceeded

limit of [LIMIT]*.

Check oil heater for proper operation.

Check for low oil level, partially closed coil supply

valves, clogged oil filters, etc.

Check the sensor wiring and accuracy.

Check configurable range in SETUP1 screen.

102

PRESTART

ALERT

HIGH MOTOR

TEMPERATURE

102->Comp Motor Winding Temp

[VALUE] exceeded limit

of [LIMIT]*.

Check motor sensors for wiring and accuracy.

Check motor cooling line for proper operation, or

restrictions.

Check for excessive starts within a short time span.

Check configurable range in SETUP1 screen.

103

PRESTART

ALERT

HIGH DISCHARGE

TEMP

103->Comp Discharge Temp

[VALUE] exceeded limit of

[LIMIT]*.

Allow discharge sensor to cool.

Check for sensor wiring and accuracy.

Check for excessive starts.

Check configurable range in SETUP1 screen.

104

PRESTART

ALERT

LOW REFRIGERANT

TEMP

104->Evaporator Refrig Temp

[VALUE] exceeded limit of

[LIMIT]*.

Check transducer wiring and accuracy.

Check for low chilled fluid supply temperatures.

Check refrigerant charge.

105

PRESTART

ALERT

LOW OIL

TEMPERATURE

105->Oil Sump Temp [VALUE]

exceeded limit of [LIMIT]*.

Check oil heater contactor/relay and power.

Check oil level and oil pump operation.

106

PRESTART

ALERT

HIGH CONDENSER

PRESSURE

106->Condenser Pressure

[VALUE] exceeded limit of

[LIMIT]*.

Check transducer wiring and accuracy.

Check for high condenser water temperatures.

107

PRESTART

ALERT

LOW LINE

VOLTAGE

107->Average Line Voltage

[VALUE] exceeded limit of

[LIMIT]*.

Check voltage supply. Check voltage transformers.

Consult power utility if voltage is low.

108

PRESTART

ALERT

HIGH LINE

VOLTAGE

108->Average Line Voltage

[VALUE] exceeded limit of

[LIMIT]*.

Check voltage supply.

Check power transformers.

Consult power utility if voltage is high.

109

PRESTART

ALERT

GUIDE VANE

CALIBRATION

109->Actual Guide Vane

Pos Calibration Required

Before Start-Up

Calibrate guide vane actuator in Control Test.

PRIMARY MESSAGE

SECONDARY MESSAGE

CAUSE/REMEDY

STARTUP IN PROGRESS

OCCUPIED MODE

Chiller is starting. Time schedule is occupied.

STARTUP IN PROGRESS

REMOTE CONTACT CLOSED

Chiller is starting. Remote contacts are enabled and closed.

STARTUP IN PROGRESS

START COMMAND IN EFFECT

Chiller is starting. Chiller START/STOP in MAINSTAT manually forced to

start.

AUTORESTART IN PROGRESS

OCCUPIED MODE

Chiller is starting after power failure. Time schedule is occupied.

AUTORESTART IN PROGRESS

REMOTE CONTACT CLOSED

Chiller is starting after power failure. Remote contacts are enabled and

closed.

AUTORESTART IN PROGRESS

START COMMAND IN EFFECT

Chiller is starting after power failure. Chiller START/STOP on MAINSTAT

manually forced to start.

PRIMARY MESSAGE

SECONDARY MESSAGE

CAUSE/REMEDY

RUNNING — RESET ACTIVE

4-20 mA SIGNAL

Auto chilled water reset active based on external input.

RUNNING — RESET ACTIVE

REMOTE TEMP SENSOR

Auto chilled water reset active based on external input.

RUNNING — RESET ACTIVE

CHW TEMP DIFFERENCE

Auto chilled water reset active based on cooler

∆T.

RUNNING — TEMP CONTROL

LEAVING CHILLED WATER

Default method of temperature control.

RUNNING — TEMP CONTROL

ENTERING CHILLED WATER

Entering Chilled Water (ECW) control enabled in TEMP_CTL screen

RUNNING — TEMP CONTROL

TEMPERATURE RAMP LOADING

Ramp Loading in effect. Use RAMP_DEM screen to modify.

RUNNING — DEMAND LIMITED

BY DEMAND RAMP LOADING

Ramp Loading in effect. Use RAMP_DEM screen to modify.

RUNNING — DEMAND LIMITED

BY LOCAL DEMAND SETPOINT

Demand limit set point is less than actual demand.

RUNNING — DEMAND LIMITED

BY 4-20 mA SIGNAL

Demand limit is active based on external auto demand limit option.

RUNNING — DEMAND LIMITED

BY CCN SIGNAL

Demand limit is active based on control limit signal from CCN.

RUNNING — DEMAND LIMITED

BY LOADSHED/REDLINE

Demand limit is active based on LOADSHED screen set-up.

RUNNING — TEMP CONTROL

HOT GAS BYPASS

Hot gas bypass option is energized. See stall prevention in the control

section.

RUNNING — DEMAND LIMITED

BY LOCAL SIGNAL

Active demand limit manually overridden on MAINSTAT table.

RUNNING —TEMP CONTROL

ICE BUILD MODE

Chiller is running under Ice Build temperature control.