Chillers with storage tanks – Carrier 19XR,XRV Hermetic Centrifugal Liquid Chillers User Manual

Page 69

69

Chillers with Storage Tanks —

If the chiller has iso-

lation valves, leave them open for the following procedures.

The letter “C” describes a closed valve. See Fig. 17, 18, 29,

and 30.

TRANSFER REFRIGERANT FROM PUMPOUT STOR-

AGE TANK TO CHILLER

1. Equalize refrigerant pressure.

a. Use the PIC II terminate lockout function on the

PUMPDOWN LOCKOUT screen, accessed from

the CONTROL TEST table to turn on the water

pumps and monitor pressures.

b. Close pumpout unit valves 2, 4, 5, 8, and 10, and

close chiller charging valve 7; open chiller isola-

tion valves 11, 12, 13, and 14 (if present).

c. Open pumpout unit/storage tank valves 3 and 6,

open chiller valves 1a and 1b.

d. Slowly open valve 5 to increase chiller pressure to

68 psig 35 psig (141 kPa) for HFC-134a. Feed

refrigerant slowly to prevent freeze up.

e. Open valve 5 fully after the pressure rises above

the freeze point of the refrigerant. Open liquid line

valves 7 and 10 until refrigerant pressure

equalizes.

2. Transfer the remaining refrigerant.

a. Close valve 5 and open valve 4.

b. Turn off the chiller water pumps using the CVC/

ICVC (or manually, if necessary).

c. Turn off the pumpout condenser water, and turn on

the pumpout compressor to push liquid out of the

storage tank.

d. Close liquid line valve 7.

e. Turn off the pumpout compressor.

f. Close valves 3 and 4.

g. Open valves 2 and 5.

h. Turn on the pumpout condenser water.

i.

Run the pumpout compressor until the pumpout

storage tank pressure reaches 5 psig (34 kPa)

(18 in. Hg [40 kPa absolute] if repairing the tank).

j.

Turn off the pumpout compressor.

k. Close valves 1a, 1b, 2, 5, 6, and 10.

l.

Turn off pumpout condenser water.

If the chilled water and condenser water pumps are not

controlled by the PIC II, these pumps must be started and

stopped manually at the appropriate times during the refrig-

erant transfer procedure.

VALVE

1a 1b 2 3 4 5 6 7 8 10 11 12 13 14

CONDITION

C

C C

C C C

Follow Steps d and e carefully to prevent damage from

freeze-up.

VALVE

1a 1b 2 3 4 5 6 7 8 10 11 12 13 14

CONDITION

C

C

C

VALVE

1a 1b 2 3 4 5 6 7 8 10 11 12 13 14

CONDITION

C

C

C

VALVE

1a 1b 2 3 4 5 6 7 8 10 11 12 13 14

CONDITION

C C

C C

VALVE

1a 1b 2 3 4 5 6 7 8 10 11 12 13 14

CONDITION C C C C C C C C C C

OIL RETURN

LINE

CONNECTION

CONDENSER

WATER

CONNECTIONS

REFRIGERANT

INLET VALVE

LEGEND

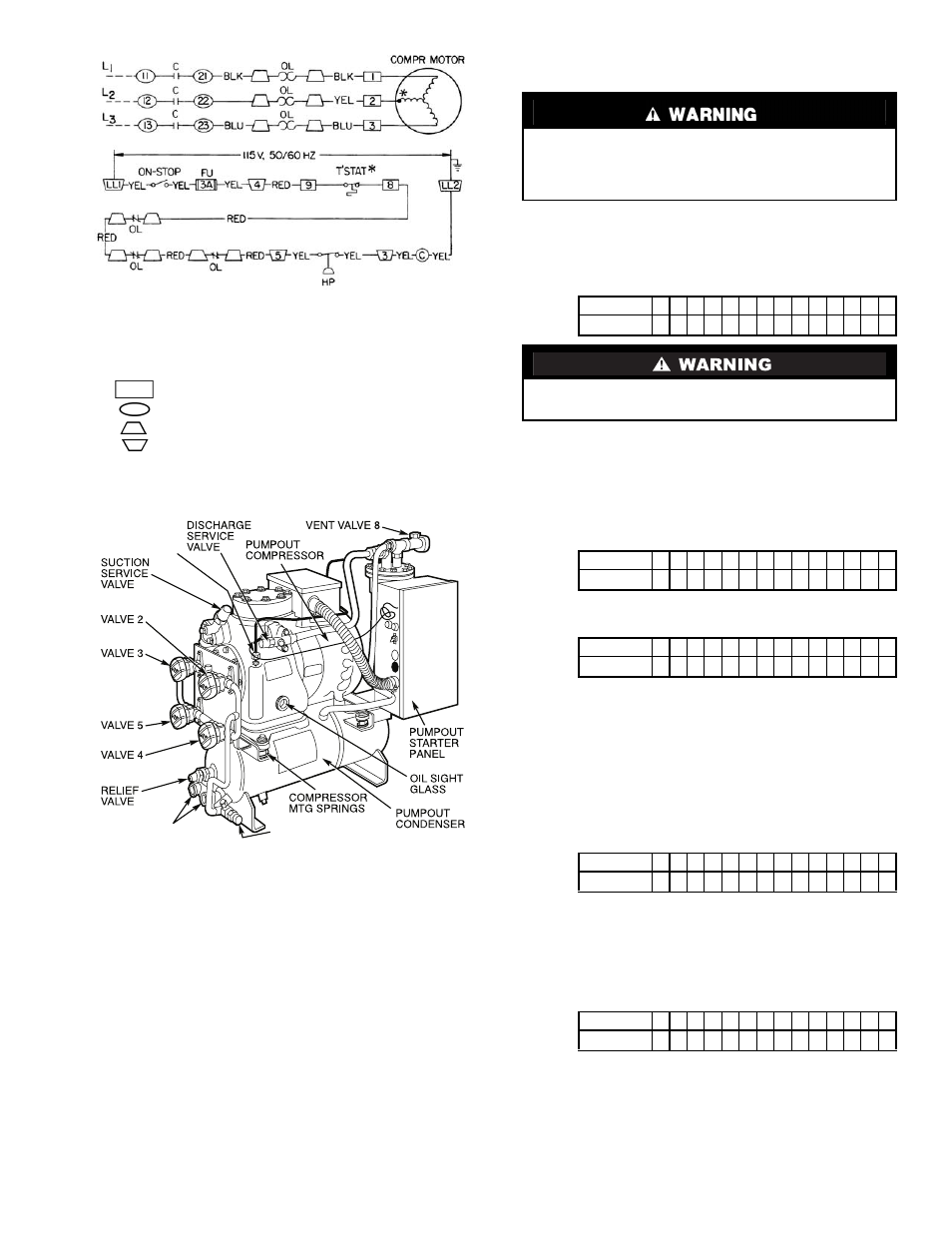

*Bimetal thermal protector imbedded in motor winding.

Fig. 35 — 19XR Pumpout Unit Wiring Schematic

C

— Contactor

FU

— Fuse, 3 Amps

HP

— High-Pressure Cutout

OL

— Compressor Overload

T’STAT

— Internal Thermostat

Compressor Terminal

Contactor Terminal

Overload Terminal

Pumpout Unit Terminal

Fig. 36 — Optional Pumpout Unit