Shunt trip (option), Default screen freeze – Carrier 19XR,XRV Hermetic Centrifugal Liquid Chillers User Manual

Page 35

35

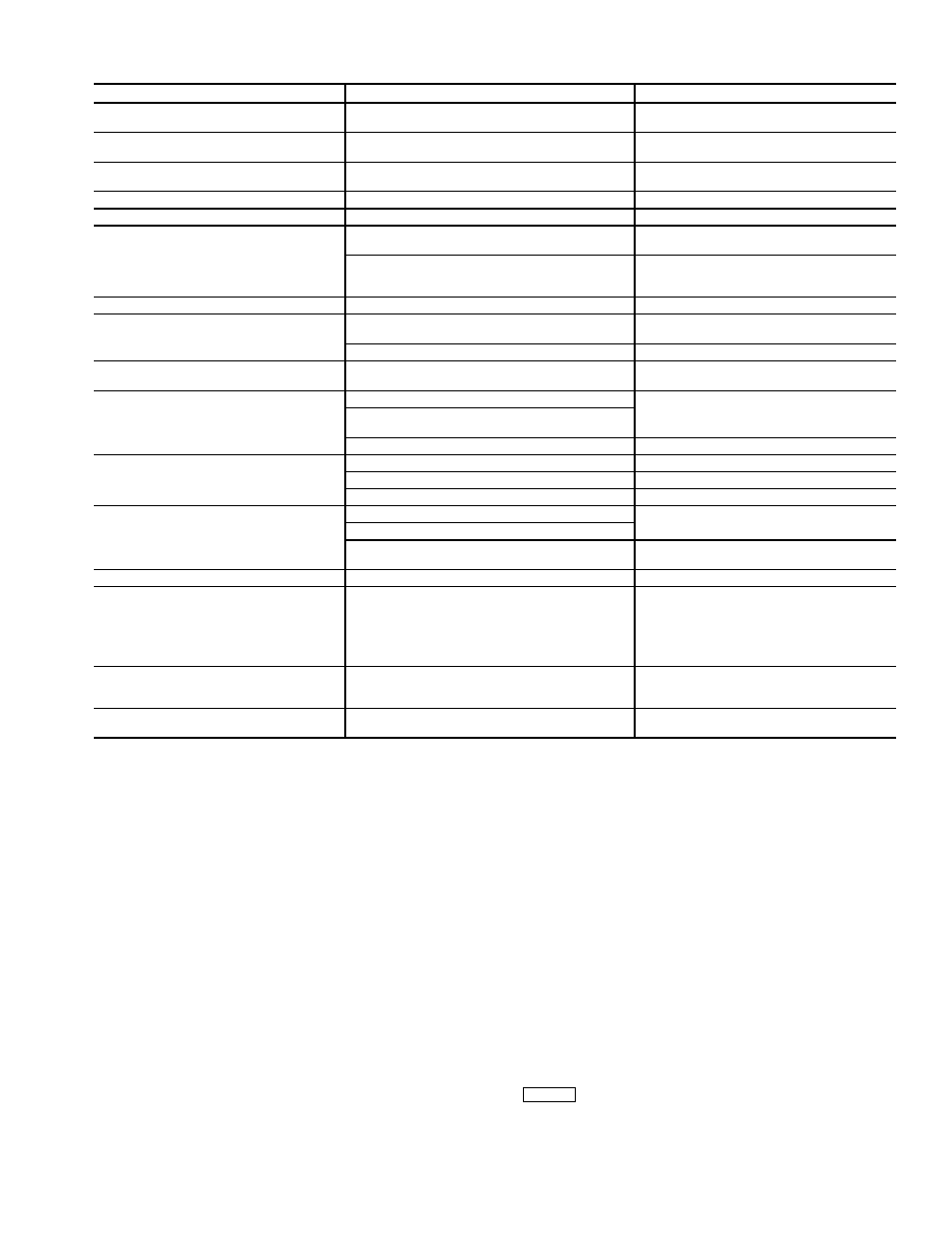

Table 3 — Protective Safety Limits and Control Settings

Shunt Trip (Option) —

The function of the shunt trip

option on the PIC II is to act as a safety trip. The shunt trip is

wired from an output on the ISM to a shunt trip equipped mo-

tor circuit breaker. If the PIC II tries to shut down the compres-

sor using a normal shutdown procedure but is unsuccessful for

20 seconds, the shunt trip output is energized and causes the

circuit breaker to trip off. If ground fault protection has been

applied to the starter, the ground fault trip also energizes the

shunt trip to trip the circuit breaker. Protective devices in the

starter can also energize the shunt trip. The shunt trip feature

can be tested using the Control Test feature.

Default Screen Freeze —

When the chiller is in an

alarm state, the default CVC/ICVC display “freezes,” that is, it

stops updating. The first line of the CVC/ICVC default screen

displays a primary alarm message; the second line displays a

secondary alarm message.

The CVC/ICVC default screen freezes to enable the opera-

tor to see the conditions of the chiller at the time of the alarm. If

the value in alarm is one normally displayed on the default

screen, it flashes between normal and reverse video. The CVC/

ICVC default screen remains frozen until the condition that

caused the alarm is remedied by the operator. Use CVC/ICVC

display and alarm shutdown record sheet (CL-13) to record all

values from default screen freeze.

Knowledge of the operating state of the chiller at the time an

alarm occurs is useful when troubleshooting. Additional chiller

information can be viewed on the status screens and the

ISM_HIST screen. Troubleshooting information is recorded in

the ALARM HISTORY table, which can be accessed from the

SERVICE menu.

To determine what caused the alarm, the operator should

read both the primary and secondary default screen messages,

as well as the alarm history. The primary message indicates the

most recent alarm condition. The secondary message gives

more detail on the alarm condition. Since there may be more

than one alarm condition, another alarm message may appear

after the first condition is cleared. Check the ALARM HISTO-

RY screen for additional help in determining the reasons for the

alarms. Once all existing alarms are cleared (by pressing the

softkey), the default CVC/ICVC display returns to

normal operation.

MONITORED PARAMETER

LIMIT

APPLICABLE COMMENTS

TEMPERATURE SENSORS OUT OF

RANGE

–40 to 245 F (–40 to 118.3 C)

Must be outside range for 2 seconds

PRESSURE TRANSDUCERS OUT OF

RANGE

0.06 to 0.98 Voltage Ratio

Must be outside range for 3 seconds.

Ratio = Input Voltage ÷ Voltage Reference

COMPRESSOR DISCHARGE

TEMPERATURE

>220 F (104.4 C)

Preset, alert setting configurable

MOTOR WINDING TEMPERATURE

>220 F (104.4 C)

Preset, alert setting configurable

BEARING TEMPERATURE

>185 F (85 C)

Preset, alert setting configurable

EVAPORATOR REFRIGERANT

TEMPERATURE

<33 F (for water chilling) (0.6°C)

Preset, configurable chilled medium for water

(SETUP1 table)

<EVAP REFRIG TRIPPOINT (set point adjustable

from 0 to 40 F [–18 to 4 C]) for brine chilling)

Configure chilled medium for brine (SETUP1

table). Adjust EVAP REFRIG TRIPPOINT for

proper cutout

TRANSDUCER VOLTAGE

<4.5 vdc> 5.5 vdc

Preset

CONDENSER PRESSURE — SWITCH

165 ± 5 psig (1138 ± 34 kPa), reset at

110 ± 7 psig (758 ± 48 kPa)

Preset

— CONTROL

165 psig (1138 kPa)

Preset

OIL PRESSURE

Cutout <15 psid (103 kPad)

Alert <18 psid (124 kPad)

Preset

LINE VOLTAGE — HIGH

>150% for one second or >115% for ten seconds

Preset, based on transformed line voltage

to ISM. Also monitored at CVC/ICVC and

CCM power input.

— LOW

<85% for ten seconds or

≤80 for 5 seconds or

<75% for one second

— SINGLE-CYCLE

<50% for one cycle (if enabled)

Default is disabled.

COMPRESSOR MOTOR LOAD

>110% for 30 seconds

Preset

<15% with compressor running

Preset

>15% with compressor off

Preset

STARTER ACCELERATION TIME

(Determined by inrush current)

150% RLA for 20 sec.

For chillers with reduced voltage mechanical

and solid-state starters

>100% RLA for 45 sec.

>100% RLA for 10 sec.

For chillers with full voltage starters

(Configures on ISM_CONF table).

STARTER TRANSITION

If ISM contact open >20 sec.

Reduced voltage starters only

CONDENSER FREEZE PROTECTION

Energizes condenser pump relay if

condenser refrigerant temperature or condenser

entering water temperature is below the configured

condenser freeze point temperature. Deenergizes

when the temperature is 5 F (3 C) above con-

denser freeze point temperature.

CONDENSER FREEZE POINT configured in

SETUP1 table with a default setting of 34 F

(1 C).

DISCHARGE SUPERHEAT

Minimum value calculated based on

operating conditions and then compared

to actual superheat.

Calculated minimum required superheat

and actual superheat are shown on

OVERRIDE screen.

VARIABLE DIFFUSER OPERATION

Detects discharge pulses caused by

incorrect diffuser position.

Preset, no calibration needed.

RESET