Flame sensor testing procedure, Warning – Bradford White EF-100T-399-3X User Manual

Page 62

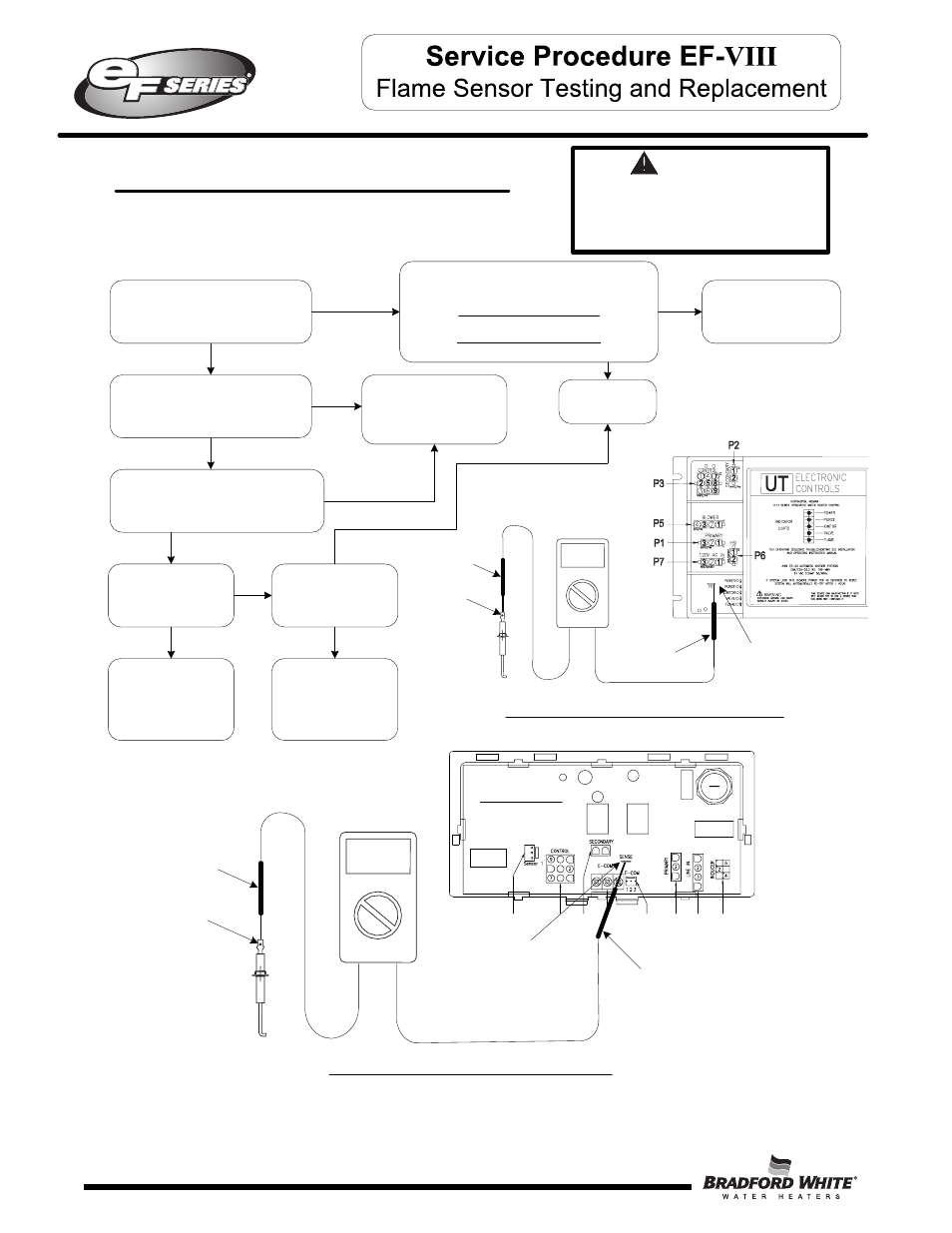

With flame sensor Disconnected

from ignition module, check

continuity to ground.

Is there continuity to ground?

N

Y

Flame Sensor Testing Procedure

Refer to illustration below, is there

a minimum of 1 micro amp during

1.5 second flame proving period?

Y

N

Is flame sensor free

of oxidation?

Clean or replace

flame sensor.

(see “Flame Sensor

Replacement

Procedure”)

N

Is ceramic of flame

sensor cracked?

Replace flame sensor.

(see “Flame Sensor

Replacement

Procedure”)

Y

N

Flame sensing circuit OK

Y

Refer to ignition module/control board

illustration.(24 volts should maintain beyond the

1.5 second flame proving period.)

Hot Surface Ignition Models:

Is there 24 volts AC at locations

P3(2) & P3(5)?

Direct Spark Ignition Models:

Is there 24VAC between

P5(5) and P5(8)?

Y

N

Call for

technical support

Replace flame sensor with

gasket

and/or wire lead.

(see “Flame Sensor

Replacement Procedure”)

Remove flame sensor from water heater.

Check continuity from tip of flame sensor

to end of wire lead.

Is there continuity?

N

Y

WARNING

120 volt potential exposure. Use caution

making voltage checks to avoid

personal injury. Flame sensor may be

too hot to handle, take necessary

precautions

62

Flame

sensor

terminal

Volt meter set to

Micro amps setting

(µA)

Meter probe

Meter probe

Flame sensor

terminal on

control board.

Flame sensor

terminal

1

2

3

8

6

5

4

3

1

1

2

1

4

1

3

3

2

1

1

5

3

P2

P4

P5

P7

P3

CONTROL BOARD

P10

P9

J1

Volt meter set to

Micro amps setting

(µA)

Meter

probe

Meter

probe

Flame sensor

terminal on

ignition module.

HOT SURFACE IGNITION MODELS

DIRECT SPARK IGNITION MODELS

62