Hp-175-225 20, Butt glaze mulli0n glazing details – Oldcastle BuildingEnvelope HP-175 User Manual

Page 20

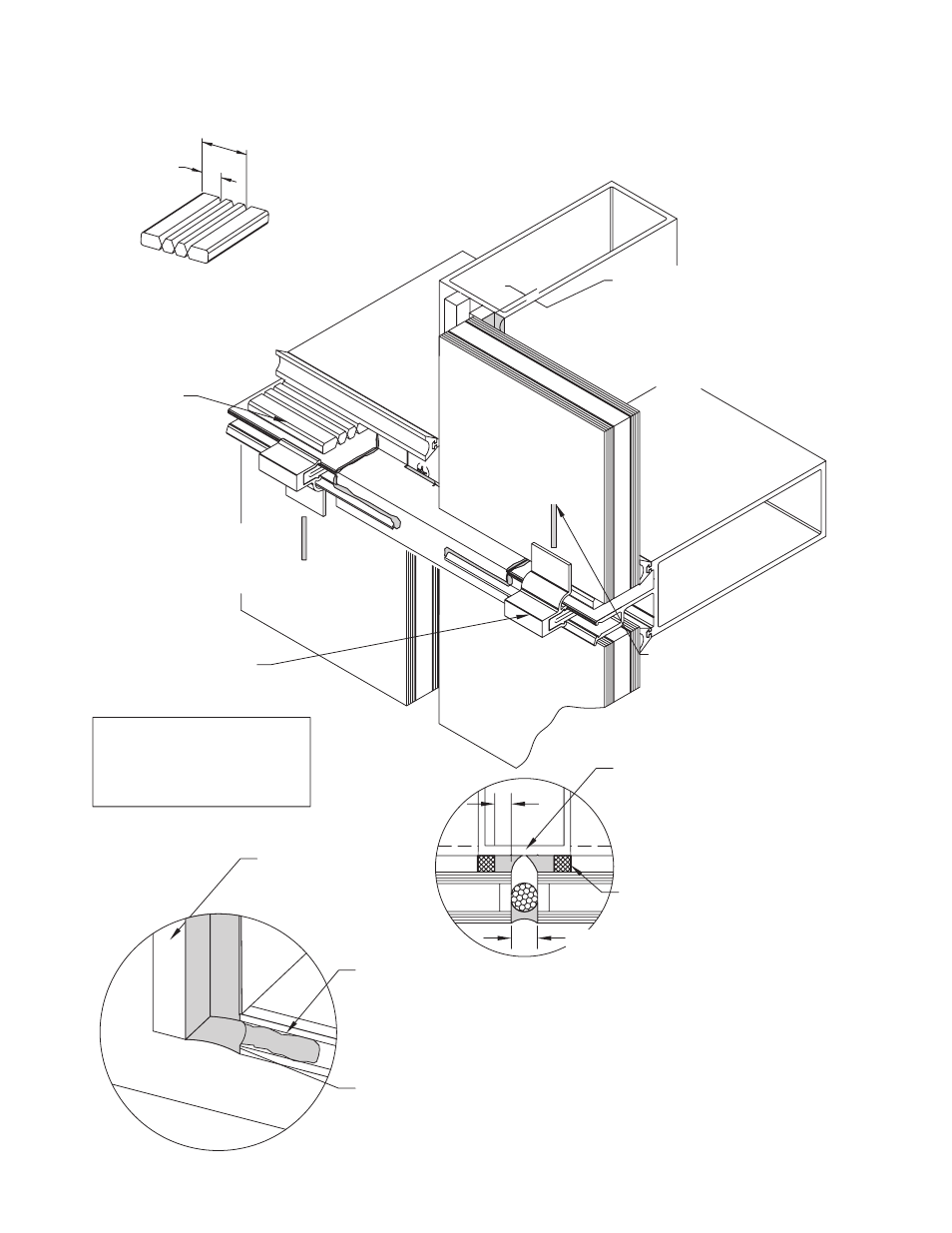

NHP-5A GASKETS.

CUT HORIZONTAL

GASKETS D. L.O.

+ 1/4" PER FOOT.

MARK LOCATION OF EACH

GLAZING CLIP PRIOR TO

INSTALLING FACE CAPS.

HP-36 TEMPORARY

CLIPS. SLIDE ONTO

GLAZING CLIPS.

SETTING BLOCK MAY BE

MODIFIED TO FIT VARIOUS

GLASS THICKNESSES. TEAR

BLOCK FOR DESIRED SIZE.

5/8"

1/4"

CAUTION:

BE CERTAIN THAT GLASS IS PLACED

FIRMLY AGAINST INTERIOR GASKET

BEFORE SETTING ON BLOCKS. GLASS

BREAKAGE CAN OCCUR AT OR NEAR

SETTING BLOCKS DUE TO THE WEIGHT

OF THE GLASS N OT ALLOWING THE

GLASS TOMOVE TOWARD INTERIOR

GASKET. LUBRICATING THE TOP OF

THE SETTING BLOCK WILL HELP

INSURE PROPER SETTING OF GLASS.

GLAZING NOTE:

GLAZE SYSTEM FROM BOTTOM

TO TOP. INSTALLING DIVERTERS

TO HORIZONAL ABOVE AS YOU

PROCEED UP BUILDING.

HP-17

SETTING

BLOCK

GLASS SIZING

HP-175 = D.L.O. + 3/4"

V2110 DSA TAPE

(LEAVE PROTECTIVE

FILM IN PLACE UNTIL

INSTALLING GLASS)

GLAZINGOPTION:

RUN V2110 TO INTERIOR

OF MULLION AND STRUCTURAL

SILICONE FROM EXTERIOR

SEAL BETWEEN

NHP-5 AND V2110

FILL GAP BETWEEN

GASKET AND TAPE

WITH SILICONE

5/16"

5/16"

1/2"

MAXIMUM SILICONE JOINT SIZE OF

5/16" X 5/16" AS SHOWN. REFERENCE

SEALANT MANUFACTURERS

SPECIFICATIONS

FOR LOAD LIMITATIONS.

BUTT GLAZE MULLI0N

GLAZING DETAILS

H P - 1 7 5 / 2 2 5 I N S T A L L A T I O N M A N U A L

20