Elecraft W1 User Manual

Page 6

6

Position trimmer potentiometer R17 (502) on the board over the silk screened outline near RP1 and RP2 with the

beveled end lined up over the beveled end of the outline. Press down until the three pins snap into the solder pads up to the

shoulders on the pins. When properly positioned, base of the pot will stand about 1/8” (3mm) above the board. Solder all

three pins.

Inspect the leads of one of the electrolytic capacitors. Note that there is a stripe with a – on the body to identify the

negative lead. The negative lead must be inserted in the round solder pad on the board. The positive lead must be inserted

in the square solder pad. There is a + symbol near that pad. The positive lead is slightly longer on most capacitors. Install the

electrolytic capacitors as follows:

__ C9, 22µF (near pot R17 at the top)

__ C8, 22µF (near lower right corner)

Install slide switch SW1. SW1 does not appear on the board. The switch location is marked POWER. Fit the six pins

through the six holes. The switch can be oriented either way. Solder one pin and make sure it is resting squarely against the

shoulders on all six pins. If necessary reheat the soldered pin while pressing down on the switch until it is fully seated. Solder

all six pins.

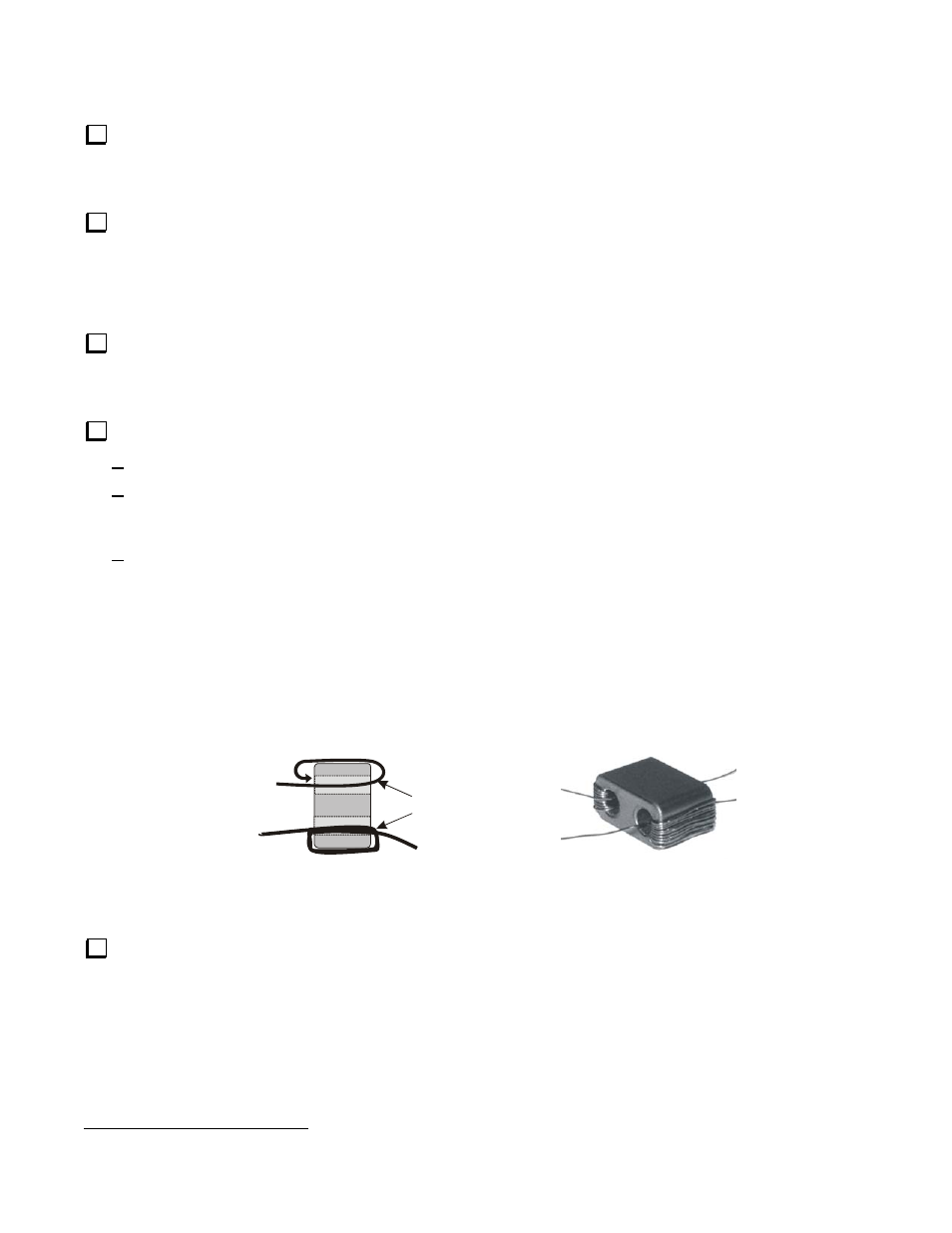

Wind the two 10-turn secondaries on the binocular core for transformer T1 as follows

2

:

Cut two 22-inch (56 cm) lengths of the #28 enameled wire.

Wind each length through one side of the binocular core as shown in Figure 2. The wire passes through the hole in

the core exactly 10 times (and passes down the side of the core 9 times), so turn 1 is when you first slip the wire

through the hole, before you wrap it around the outside.

Tin all four leads up to about 1/8” (6 mm) of the core using one of the following techniques:

1. Heat stripping: Melt a blob of solder on the tip of your iron and insert the clipped end of the lead in the blob.

The insulation will bubble and vaporize after about 5 seconds. Add solder and feed the wire into the blob up to

the edge of the core, then slowly pull the wire out of the solder. If any enamel remains on the lead, scrape it

away.

2. Burn the insulation off by heating it with a butane lighter for a few seconds. Remove any residue with

sandpaper, then tin the bare wire.

3. Scrape the wire with a sharp tool. Take care not to nick the wire. Remove all the insulation around the entire

circumference of the wire, then tin the wire.

EACH WIRE PASSES

THROUGH CENTER

10 TIMES

BINOCULAR CORE (CUTAWAY VIEW)

COMPLETED WINDINGS

Figure 2. Winding T1 Secondaries.

Cut two 1-1/2” (3.8 cm) lengths of the #18 insulated wire. Strip 3/8” (9mm) of the insulation from each end, leaving

3/4” (19mm) of insulation covering the center section of each wire. Very lightly tin each wire to keep the strands from

separating.

2

A pre-wound transformer is available from an Elecraft-approved source. See www.elecraft.com for details