Elecraft W1 User Manual

Page 10

10

Turn the POWER switch OFF, then install a 9-volt battery in the holder or connect a d-c supply between 9 and 14VDC

to J2 (positive to center pin).

Turn the POWER switch ON. The FORWARD POWER LEDs should flash, then the SWR LEDs and finally the

RANGE LEDs. The green 1.4 watt RANGE LED should then stay on, indicating the W1 is ready at the lowest power range.

Connect your DMM negative probe to the ground test point between U2 and J4 and place the positive probe on TP1 near

the center of the board. Adjust the CAL trimmer potentiometer for 4.50 VDC at TP1. This will calibrate your W1 to measure

power quite accurately over its range. Typically the accuracy will be at least within 0.5 dB with each LED illuminating just

as the indicated power level is reached. For example, the “5” LED will light just as the power reaches 0.5, 5 or 50 watts. The

range is indicated on the three RANGE LEDs.

i

If you have an RF wattmeter that you are certain is more accurate than about 0.5 dB, you can use it to

calibrate your W1 by monitoring the power and adjusting CAL so the readings match.

Apply RF to the INPUT with a suitable load connected to the OUTPUT. The FORWARD POWER and RANGE lights

will illuminate showing the RF power and the SWR lights will indicate the standing wave ratio. The FORWARD POWER

and SWR displays are peak reading: they indicate the highest instantaneous power or SWR detected.

Serial Interface

In addition to the LED readout provided on the W1, data is also available in serial format at data jack J25. See Serial

Interface Commands on page 14 for a complete list of the commands and responses.

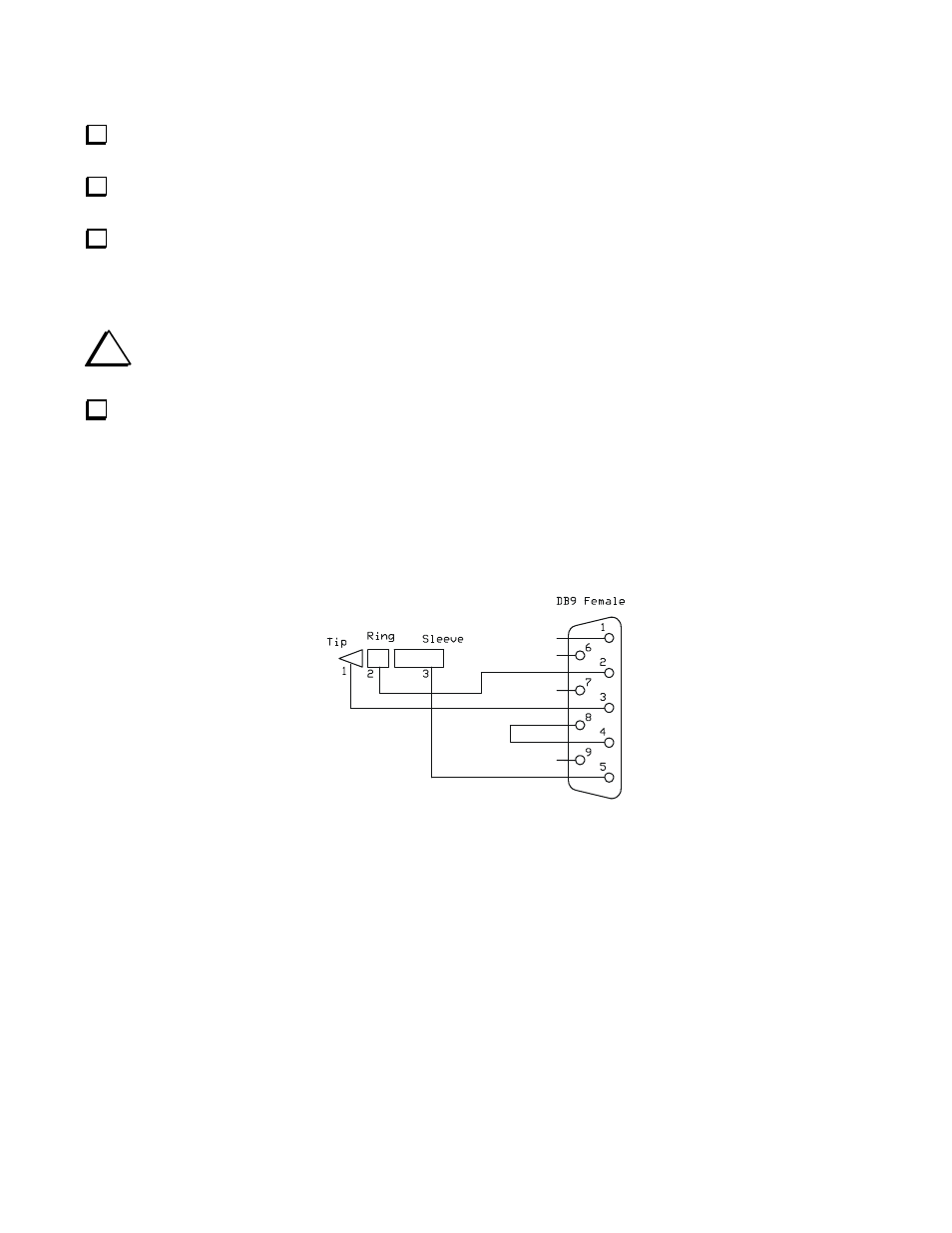

Figure 6 shows the connections recommended to provide this data to a computer serial port. A kit of the parts needed to

fabricate a 6-foot (1.8 meter) serial interface cable as shown below is available from Elecraft. Order W1SERKT.

Figure 6. Serial Interface Cable Connections.

Troubleshooting

If the LEDs do not flash when the POWER is switched ON, check the orientation of diode D4 if using internal battery or D5

if using an external supply.

Most problems can be traced to the wrong component or a diode, electrolytic capacitor or integrated circuit installed

backwards. If a specific LED fails to light, but the other LEDs associated with it do, the LED is probably defective or

installed backwards. Another critical point to check are the secondary windings on T1. Be sure the leads are properly tinned.

Reheat the leads where they enter the pads by touching your soldering iron to the tinned area of the wire near the solder pad.

Often this will serve to create a good electrical contact with the wire by burning remaining enamel off the wire without

overheating the solder pad.