Elecraft W1 User Manual

Page 4

4

Assembly Procedure

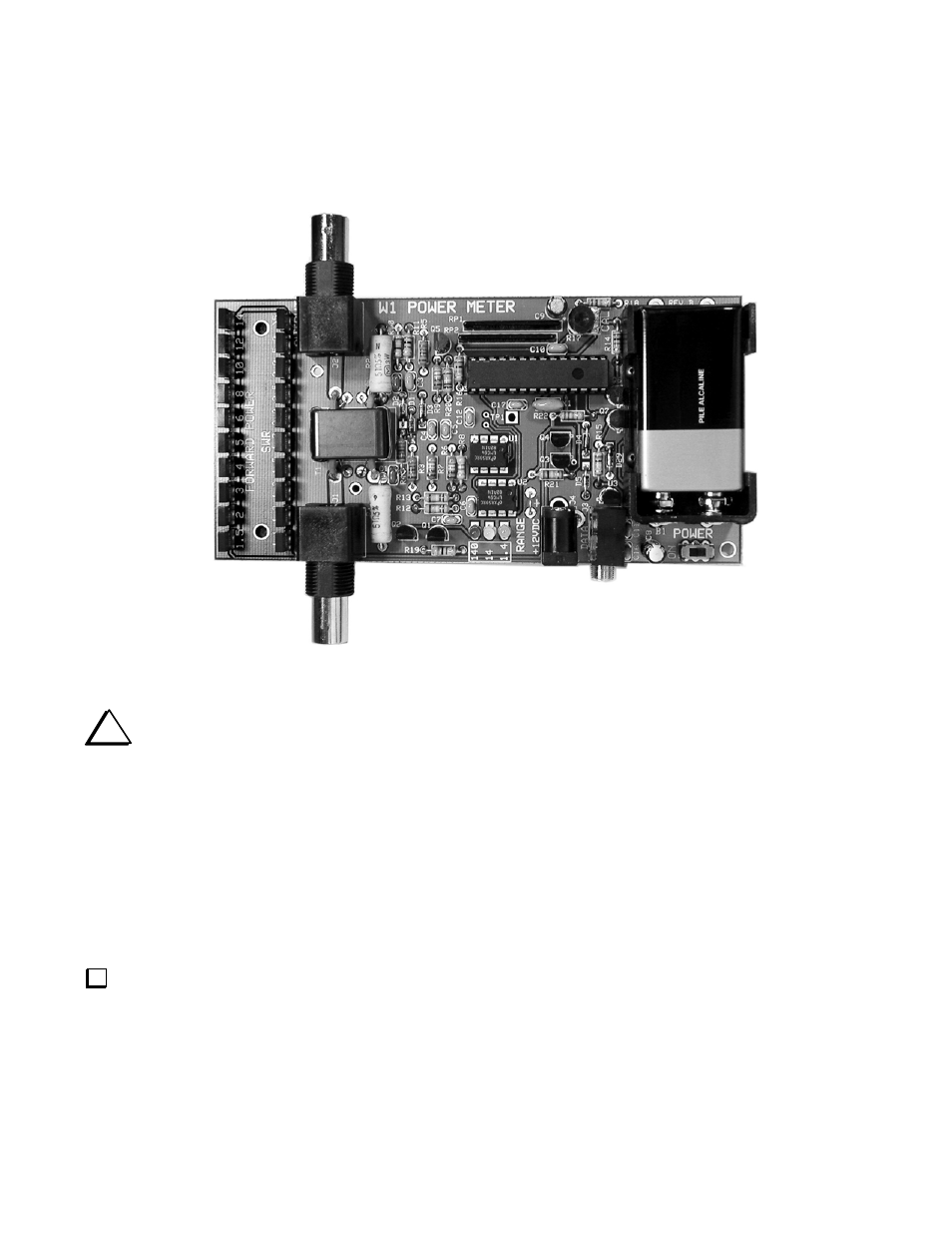

The finished Power Meter is shown in Figure 1. We recommend you follow the assembly procedure below and refer to this

figure as needed.

Figure 1. Assembled W1 Power Meter.

i

Use adequate ventilation when soldering; avoid inhaling smoke or fumes. Always wash your hands after

handling solder, as lead residue is highly toxic.

When applying solder, use the minimum amount required to surround the component lead and make good contact with its

printed-circuit pad. You don't need a "fillet" (build-up) of solder. This will avoid unwanted solder bridges and any need to

clean the PC boards.

The solder must flow onto both the component lead and its PC board pad. To ensure that both will be heated at the same time,

the tip of the iron should contact both the component lead and the PC board pad before solder is applied.

Solder joints should be clean and shiny. If a joint appears dull or has fine cracks, it is probably cold. Cold solder joints should

be cleaned and re-soldered. First, use solder wick (desoldering braid) to remove the old solder. Then apply fresh solder. If

you have many cold solder joints, it probably indicates that your soldering iron temperature is too low, or that the tip or

solder itself is defective.

Install the fixed resistors listed below. Position each resistor against the board within the outline, solder and trim the

leads flush on the bottom. If you position the board so the legends are right side up, you can work clockwise around the board

starting with R10 near the space for R2 at the top (Resistors R1 and R2 will be installed later). Save one of the clipped

resistor leads to use for a ground test point later.

__ R10, 240Ω (red-yel-brn)

__ R11, 2K (red-blk-red)

__ R5, 332K 1% (org-org-red-org)

__ R9, 49.9K 1% (yel-wht-wht-red)

Continued on next page.