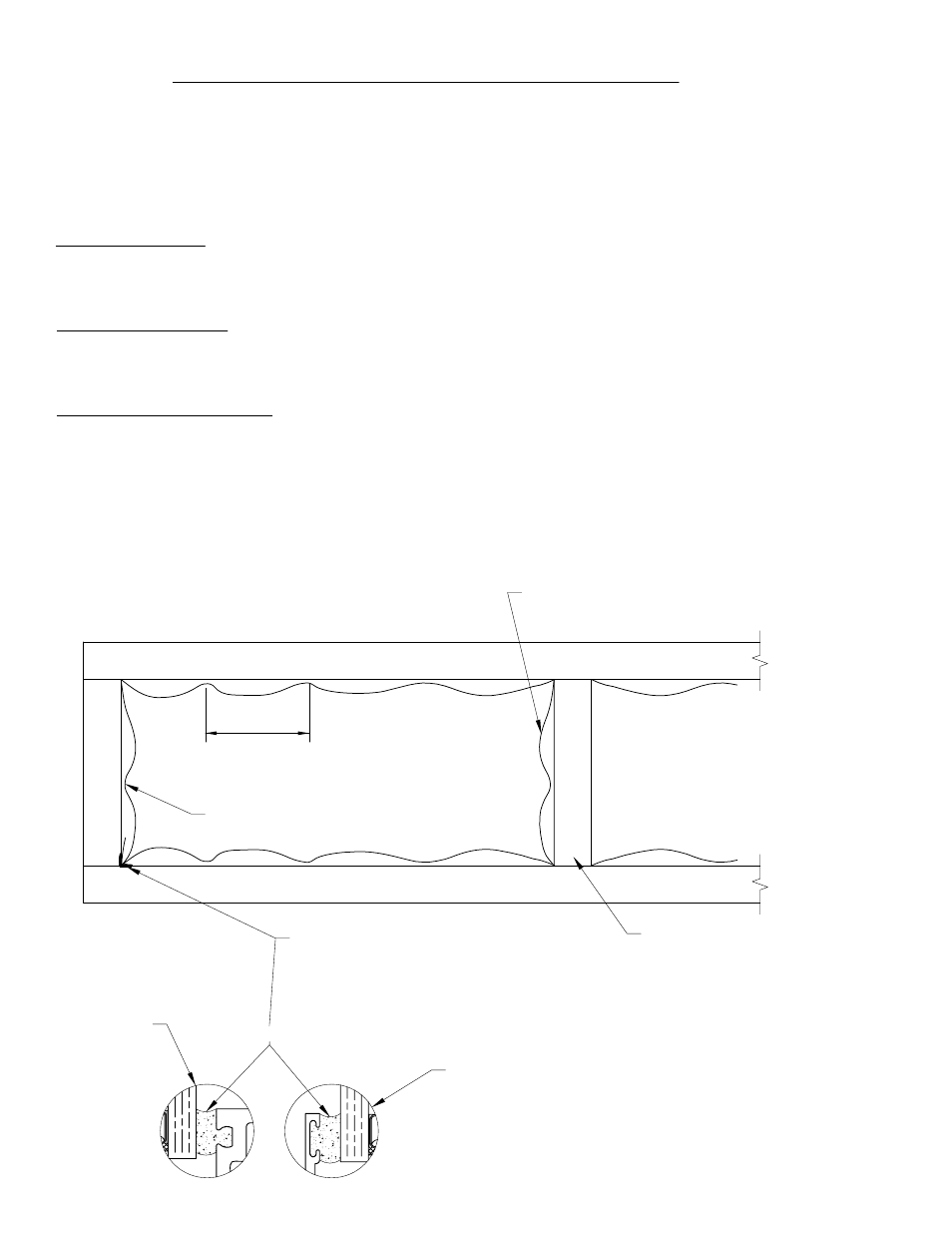

Filling the structural glazing gap, Step 8) installation of glazing gasket, Fig. 67 – EFCO 945 Series User Manual

Page 47

VARIES

HEAD

JAMB

8" - 12"

SILL

SEAL 1" VERTICALLY AND HORIZONTALLY

IN THE GASKET RACES WITH SILICONE

TYPE SEALANT AT ALL CORNERS. SEAL

THE ENDS OF ALL GASKETS. CLEAN OFF

ANY EXCESS SEALANT.

SEALANT

STEP 8) INSTALLATION OF GLAZING GASKET

INCLUDES CAPTURED AND STRUCTURAL GLAZED MULLION SYSTEMS

SECTION IX - GLAZING (cont.)

MDM

01/2007

INSIDE GLAZED

Install W160 gasket at the vertical members. See note below. Install W160 gasket into the

horizontal members so they fit tightly into the vertical gaskets. (D.L.O. + 2%)

OUTSIDE GLAZED

Install W160 gasket at the vertical members. See note below. Install W160 gasket into the

horizontal members so they fit tightly into the vertical gaskets. (D.L.O. + 2%)

STRUCTURAL GLAZED

Install W160 gasket at the vertical members. See note below. Install W160 gasket into the

horizontal members so they run continuously from perimeter to perimeter across the structural

glazed mullion.

NOTE: To install W160 gasket, start by pushing the gasket in place at the ends. Move to the

middle, then to quarter points and work the "WAVES" toward the ends.

DO NOT STRETCH

THE GASKET OR IT WILL RETURN TO ITS ORIGINAL FORM, CREATING GAPS AT THE

GASKET INTERSECTIONS.

See Figure 67 below.

OUTSIDE GLAZED

INSIDE

GLAZED

NOT USED FOR

STRUCTURAL GLAZED

VERTICAL

JAMB GASKET

RUNS THRU

[FIG. 67]

PAGE 45