Sealing the expansion mullion, Fig. 32, Fig. 35 – EFCO 945 Series User Manual

Page 31: Fig. 33, Con’t) step 5) sealing the expansion mullion

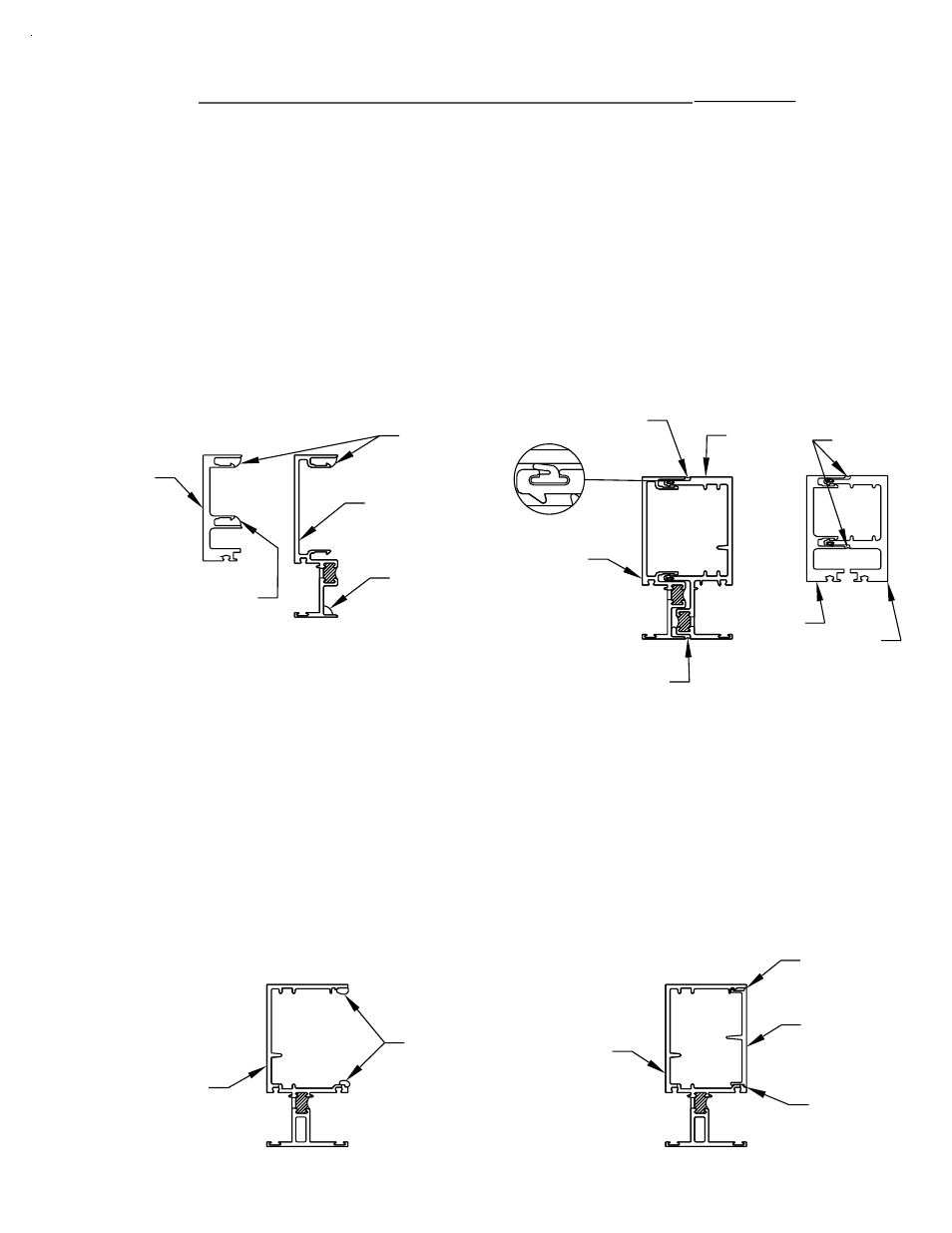

If installing an expansion mullion, apply silicone type sealant in the locations

shown below. The interior should be sealed up 6" from the subsill, and the entire

exterior joint should be sealed. Apply enough sealant so that when the expansion

mullion is collapsed, it will squeeze the sealant out and create a good seal. Clean off

any excess sealant. See Figures 32 and 33.

SEAL 6" UP

FROM

SUBSILL

SEAL ENTIRE

JOINT

SEALANT

If installing an intermediate vertical mullion, apply silicone type sealant to the

intermediate vertical mullion in the locations shown below. Both sides of the entire

mullion should be sealed. Apply enough sealant so that when the filler is snapped, it

will create a good seal. Wipe off excess sealant. See Figures 34 and 35.

STEP 6) SEALING THE INTERMEDIATE VERTICAL MULLION

SNAP IN FILLER

[FIG. 34]

8308

SEAL

ENTIRE

JOINT

[FIG. 32]

8469

8312

8309

SEALANT

SEALANT

[FIG. 35]

8308

BAB 11/2000

8469

SEALANT

[FIG. 33]

8312

SEALANT

8313

8468

SEALANT

SECTION VIII - INSTALLATION

(CON’T)

STEP 5) SEALING THE EXPANSION MULLION

INCLUDES CAPTURED AND STRUCTURAL GLAZED MULLION SYSTEMS

PAGE 29