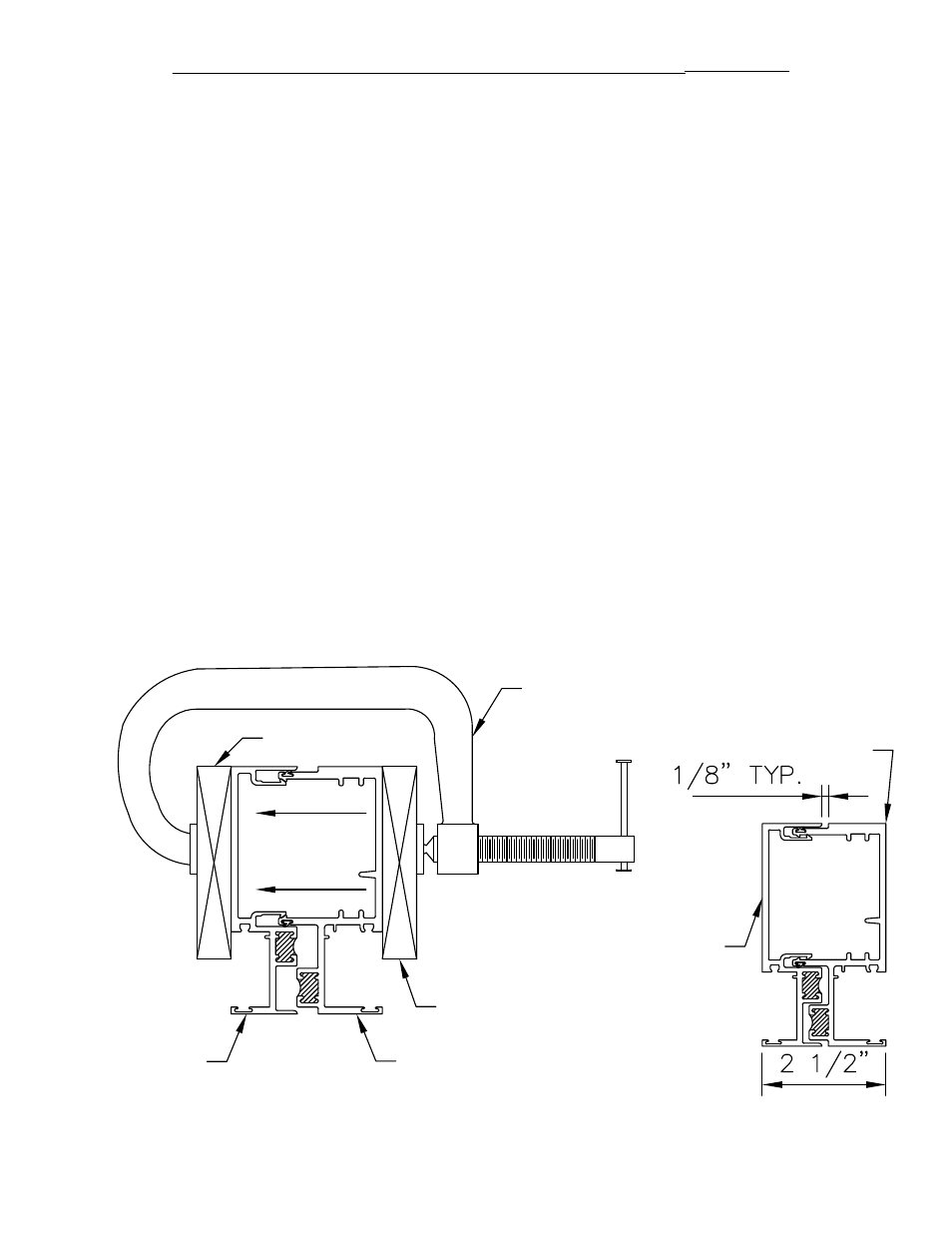

Snapping the expansion mullion, Con't), Fig. 39 – EFCO 945 Series User Manual

Page 33: Fig. 40, Step 8) snapping the expansion mullion

[FIG. 39]

WOOD BLOCK

8312

8313

WOOD BLOCK

[FIG. 40]

3-2009

INCLUDES CAPTURED AND STRUCTURAL GLAZED MULLION SYSTEMS

STEP 8) SNAPPING THE EXPANSION MULLION

(CAPTURED SYSTEM SHOWN, STRUCTURAL GLAZED SYSTEM SIMILAR)

SECTION VIII - INSTALLATION

(CON'T)

To snap the expansion mullion together, line up the mullion halves and

gaskets. See Figure 39. Place one clamp at the bottom of the expansion

mullion using wood blocks to protect the extrusions. Tighten the C-clamp until

the expansion mullion halves begin to snap together. Place another set of

wood blocks and a C-clamp at the middle of the expansion mullion and tighten

it. Then repeat the same process on the top. Tighten the C-clamps until the

sight line becomes 2 1/2". It may be necessary to work from one clamp to the

next several times, or move the clamps, to ensure the mullions are snapped

together evenly. See Figure 40. DO NOT try to hammer the expansion mullion

together! This will dent, bend, scratch, or deform the expansion mullion and

may cause it to leak. Anchor the head using the requirements on Page 27

before installing the next ladder using the requirements on Page 30. If this is

the last ladder, anchor the jambs as required on Page 28 and proceed to the

perimeter sealing process, Step 11 on Page 33.

C-CLAMP

PAGE 31

8312

8313