Step 5) end dam installation, Step 6) chalk line for subsill, Fig. 10 – EFCO 945 Series User Manual

Page 17: Con’t)

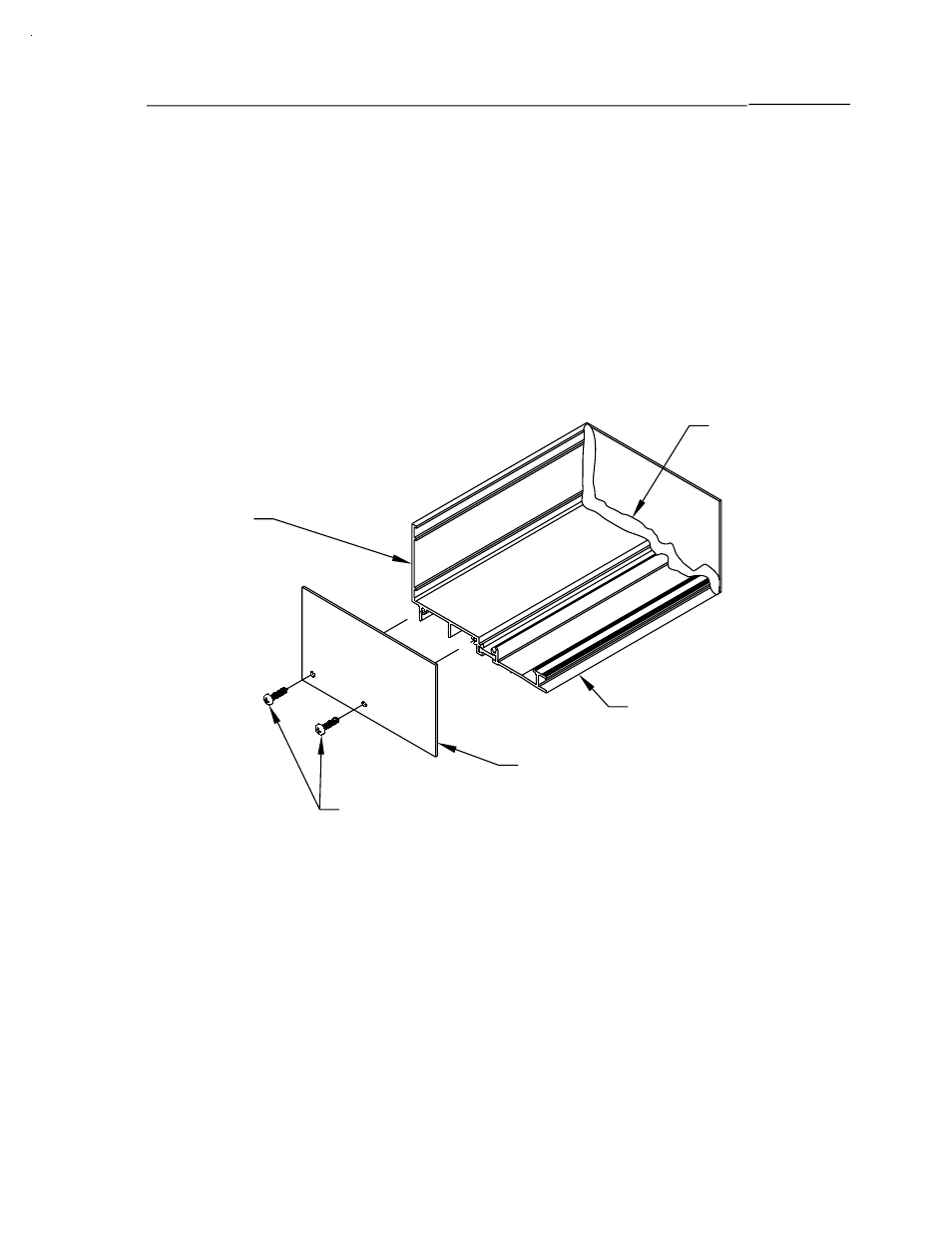

STEP 5) END DAM INSTALLATION

The end dam is to be attached to the subsill with 2 SLQ1 fasteners on

each end. Seal the end of the subsill with silicone sealant before

attaching the end dam to the subsill. Tool the sealant at the interior joint

of the end dam to ensure a good watertight seal. See Figure 10 below.

STEP 6) CHALK LINE FOR SUBSILL

Before installing the subsill, measure the distance from the exterior of

the condition to the desired location at the EXTERIOR of the subsill. (The

exterior of the subsill will be flush with the rest of the system.) Do this at

both ends of the condition. Snap a chalk line between the two marks to

align the subsill. If the condition is too wide for just two marks, measure

every 15 feet and snap a chalk line.

[FIG. 10]

APPLY

SEALANT

TO ENDS

OF THE

SUBSILL

BEFORE

ATTACHING

END DAM

SLQ1

BAB 11/2000

TOOL SEALANT

AT JOINT

2G22

K458

END DAM

SECTION V - SUBSILL FABRICATION

(CON’T)

INCLUDES CAPTURED AND STRUCTURAL GLAZED MULLION SYSTEMS

PAGE 15