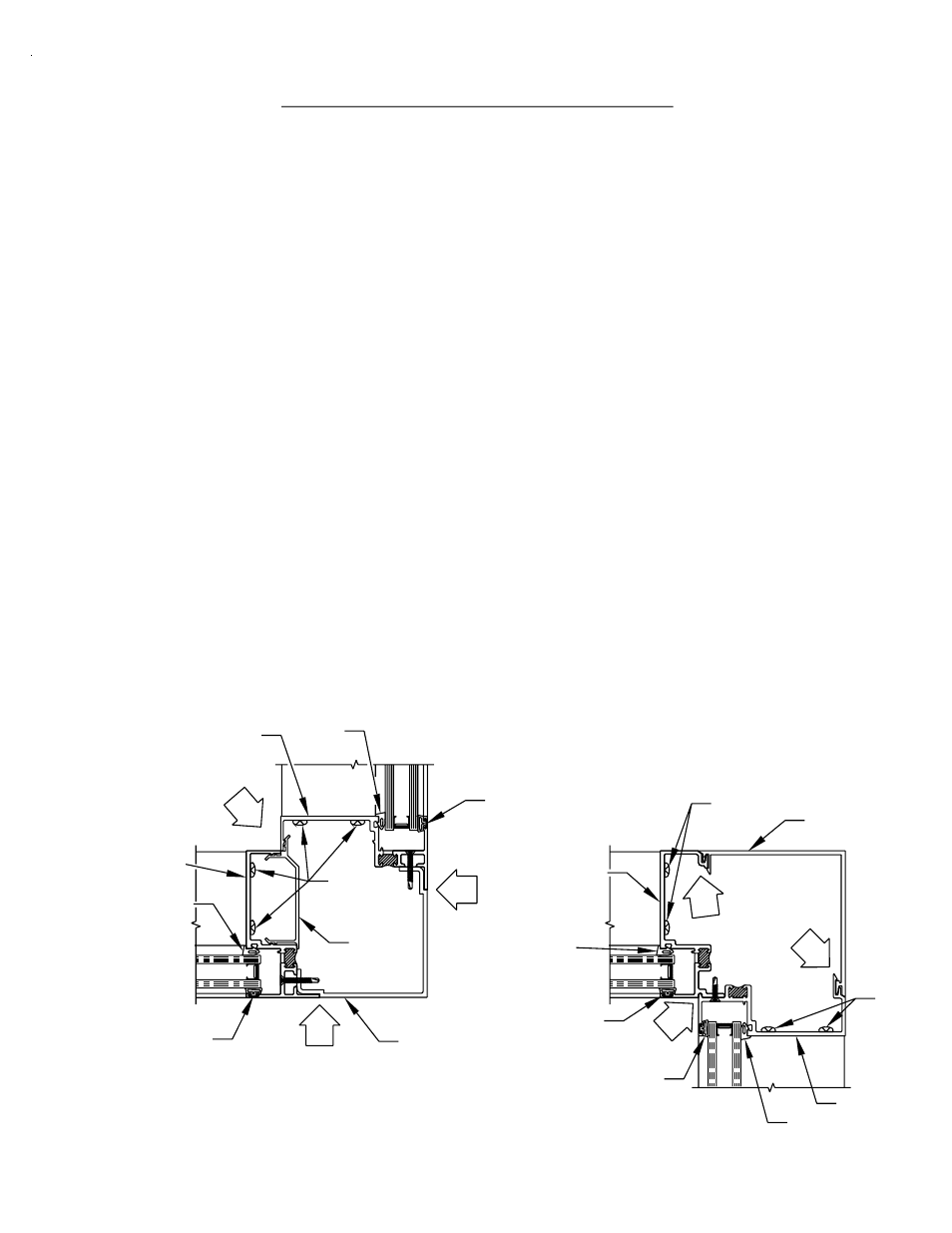

Corners, Ii door fr, Corner identification and assembly – EFCO 945 Series User Manual

Page 23: Fig. 19

S

S

S

S

S

S

STC8

STC8

W160

STK8

STC8

8334

8331

8332

9297

8334

8342

8333

SECTION VI - CORNERS

CORNER IDENTIFICATION AND ASSEMBLY

DPS 04/2001

WC12

W160

STK8

[FIG. 19]

WC12

W160

Proper identification of the required corner members is necessary to ensure a timely

installation process.

1) 90˚ captured outside corner

2) 90˚ captured inside corner

3) 90˚ S.S.G. inside corner

4) 90˚ S.S.G. outside corner

5) 135˚ S.S.G. outside corner

Determine that the subsill has been installed according to the instructions listed on Pages 13

through 20. Assemble the appropriate extrusions to create the required corner member.

Utilize the fasteners shown in Figures 19 through 21A on Pages 21 and 22. The fasteners

should be installed 6" from each end and 12" on center. Install the appropriate assembled

corner member into the subsill. It may be necessary to temporarily brace the vertical corner

member until the adjacent ladders are installed and anchored.

If door openings are required on a run that incorporates a corner member, begin at the door

frame and assemble towards the corner area with the required ladders. Unassembled

corner extrusions must be attached to the ladders, and the corner member must be

assembled after installation of both adjacent ladders.

STK4

W160

WC12

WC12

PAGE 21