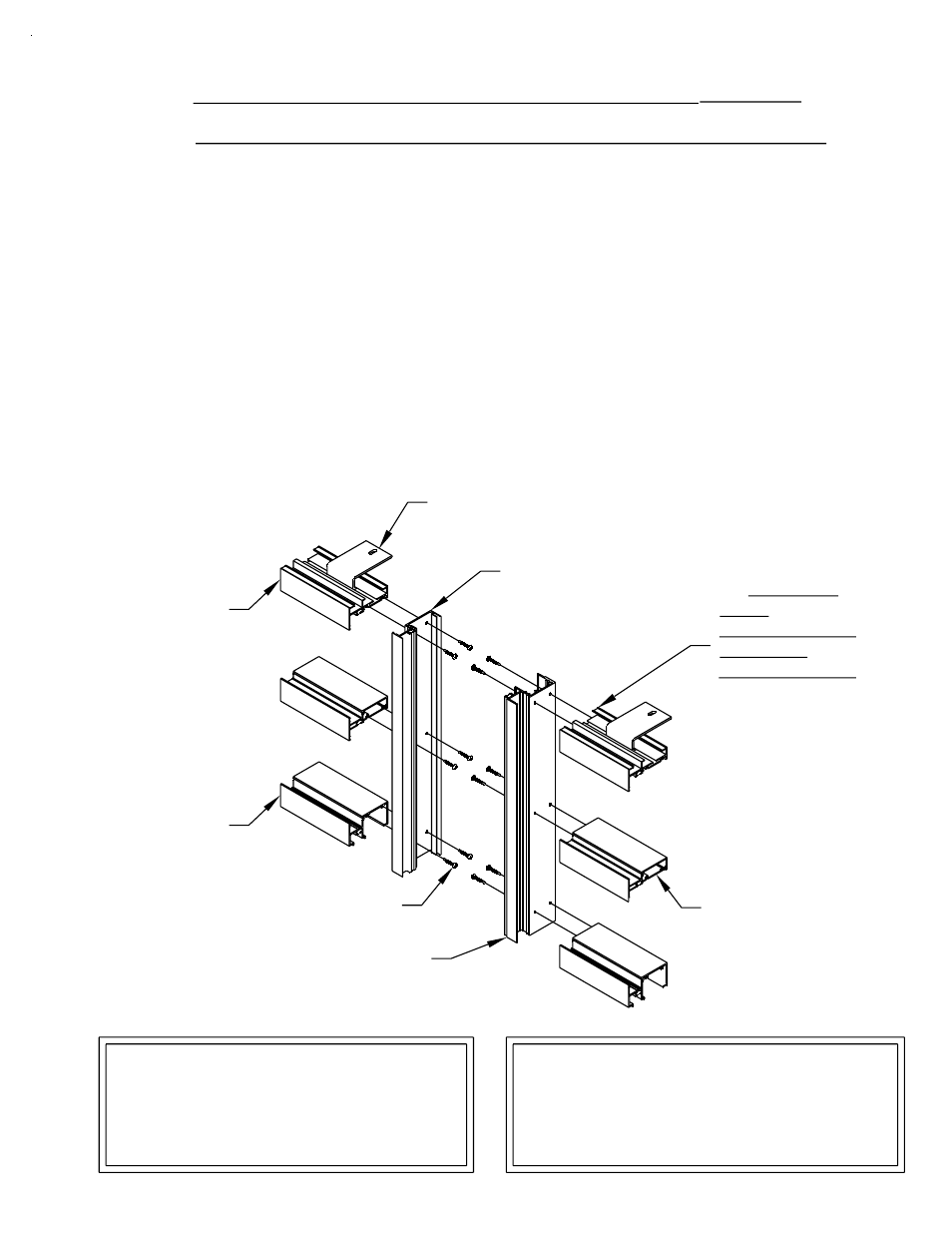

Fig. 4, Con’t), Step 3) horizontals to expansion mullion assembly – EFCO 945 Series User Manual

Page 13: Captured and structural glazed mullion systems

To ensure that the unit will assemble correctly, verify that the expansion mullion

halves are fabricated opposite of each other. See Fig. 4. Apply butyl type sealant to the

ends of all horizontal members that come in contact with the expansion mullion. Install

anchors into the head. Before assembly, apply wax lubricant to all STC8 fasteners.

Fasten the expansion mullion to all horizontal members. Fasten the other vertical mullion,

jamb, etc. to the other end of the horizontals. Make sure that you have applied butyl type

sealant to the other ends of the horizontal members. Wipe off all excess sealant.

ANCHOR

FT46 (SHOWN)

FT47 OPTIONAL

STC8

EXPANSION MULLION

HALF (DEEP POCKET)

(8313)

NOTE: For inside glazed systems, install

exterior glazing gasket (WC12) prior to

assembly. For outside glazed systems,

install interior glazing gasket (WNE0) prior

to assembly of units.

SILL

(8344)

HEAD

(8300)

INT. HORIZONTAL

8301 - (SHOWN)

8302 - OPTIONAL

GENERAL NOTE: If the D.L.O. is 36" wide or less, 2

strap anchors are required. D.L.O.’s greater than 36"

require 3 anchors. Anchor widths and locations

should be verified by a structural engineer for job

specific conditions.

[FIG. 4]

BAB 11/2000

APPLY BUTYL

TYPE SEALANT

TO THE AREA

THAT

CONTACTS THE

VERTICAL

MULLION FILLER

BEFORE

ATTACHING TO

THE EXPANSION

MULLION.

EXPANSION MULLION

HALF (SHALLOW

POCKET)

(8312)

SECTION IV - UNIT ASSEMBLY

(CON’T)

CAPTURED AND STRUCTURAL GLAZED MULLION SYSTEMS

STEP 3) HORIZONTALS TO EXPANSION MULLION

ASSEMBLY

(CAPTURED SYSTEM SHOWN, STRUCTURAL GLAZED SYSTEM SIMILAR)

PAGE 11