Function keys, Using the electronic indicator system, Electronic indicator system -25 – Craftsman 113.248510 User Manual

Page 25

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

FUNCTION KEYS

The five keys located to the right of the display are

the function keys. They are:

j ON/OFF

j

— Turns the display "On” or “Off”

j

BEVEL

j

- - - -

Selects the Bevel Angle display

jjTENj _ Selects the Blade Tension display

I — Selects the Blade Speed display

fset

: — Sets the Bevel Angle to Zero

NOTE: In order to extend battery life the display will

shut off approximately five (5) minutes after the last

key was pressed.

USING THE ELECTRONIC INDICATOR

SYSTEM

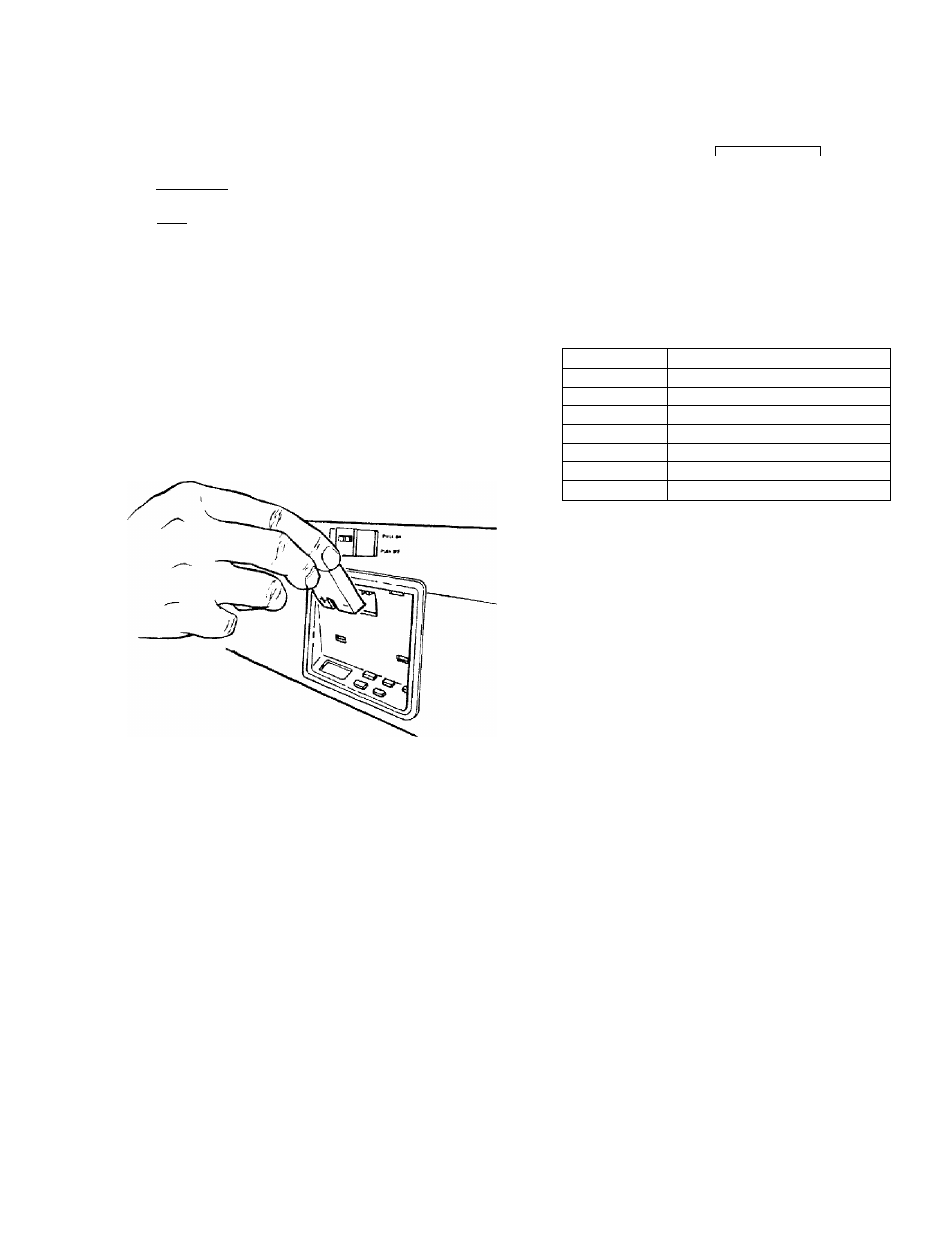

1. Setting the Bevel Angle Reference Point.

Whenever the battery is installed or a new zero

point is desired, it is necessary to set the zero

reference. Normally the zero reference is set with

the blade vertical to the table. When the blade is

in the desired position for the zero point do the

following.

a. Press the

key if display is off.

b. Press the

key, then the j

key.

n n

U.

LI

c. Display should read:

2. Selecting Blade Tension

a. Press the [

onwf

I key if display is off.

b. Press the [ ™ | key.

c. The digital display will show one of seven

tension settings. Turn the tension knob until

the correct read-out appears for the blade or

sanding belt you have selected.

Read-out

Indicates correct tension for:

L

Loose - no tension

S

Sanding Belt

. 125

1/8" blade

.250

1/4" blade

.375

3/8" blade

.500

1/2" blade

Overtensioned

Blade Speed

The digital display will read out one of two

starting speeds, depending on where the motor

belt is positioned on the pulleys. The two starting

speeds are 3000 FPM and 1500 FPM. The speed

ranges for each starting point are:

3000

1500

2800

1400

*2600

‘1300

2400

1200

2200

1100

2000

1000

The band saw motor will stall if the blade speed

drops two steps’ below operating speed.

NOTE: It is important to maintain maximum

cutting efficiency by keeping the blade speed as

fast as possible. Do not feed the work piece too

rapidly. It will overload the motor and stall the

blade.

25