Vermont castings, majestic products dvrtsb – Vermont Casting DVRTSB User Manual

Page 7

7

Vermont Castings, Majestic Products DVRTSB

10003848

The gas pipeline can be brought in through the side and

back of the fireplace as well as the bottom. Knockouts

are provided on the bottom behind the valve to allow for

the gas pipe installation and testing of any gas connec-

tion. It is most convenient to bring the gas line in from

the right side of the valve as this allows fan installation

or removal without disconnecting the gas line.

The gas line connection can be made with properly

tinned 3/8” copper tubing, 3/8” rigid pipe or an ap-

proved flex connector. Since some municipalities have

additional local codes, it is always best to consult your

local authority and the CSA-B149.1 installation codes.

For USA installations consult the current National Fuel

Gas Code, ANSI Z223.1.

Gas Line Installation

When purging the gas lines, the front

glass must be removed.

Always check for gas leaks with a mild

soap and water solution. Do not use an

open flame for leak testing.

The fireplace valve must not be sub-

jected to any test pressures exceeding

1/2 psi. Isolate or disconnect this or any

other gas appliance control from the gas

line when pressure testing.

Model

Fuel

Gas Control

BTU/h

BTU/h

DVRTSB RN Nat

Millivolt

30,000

21,000

DVRTSB RP Prop

Millivolt

30,000

22,500

Gas Specifications

Max.

Input

Min.

Input

Gas Inlet and Manifold Pressures

Natural

LP (Propane)

Inlet Minimum Pressure

5.5” w.c.

11.0” w.c.

Inlet Maximum Pressure 14.0” w.c.

14.0” w.c.

Manifold Pressure

3.5” w.c.

10.0” w.c.

DVRTSB

Certified To

ANSI Z21.88b-1999 / CSA 2.33b-M99

Vented Gas Fireplace Heaters

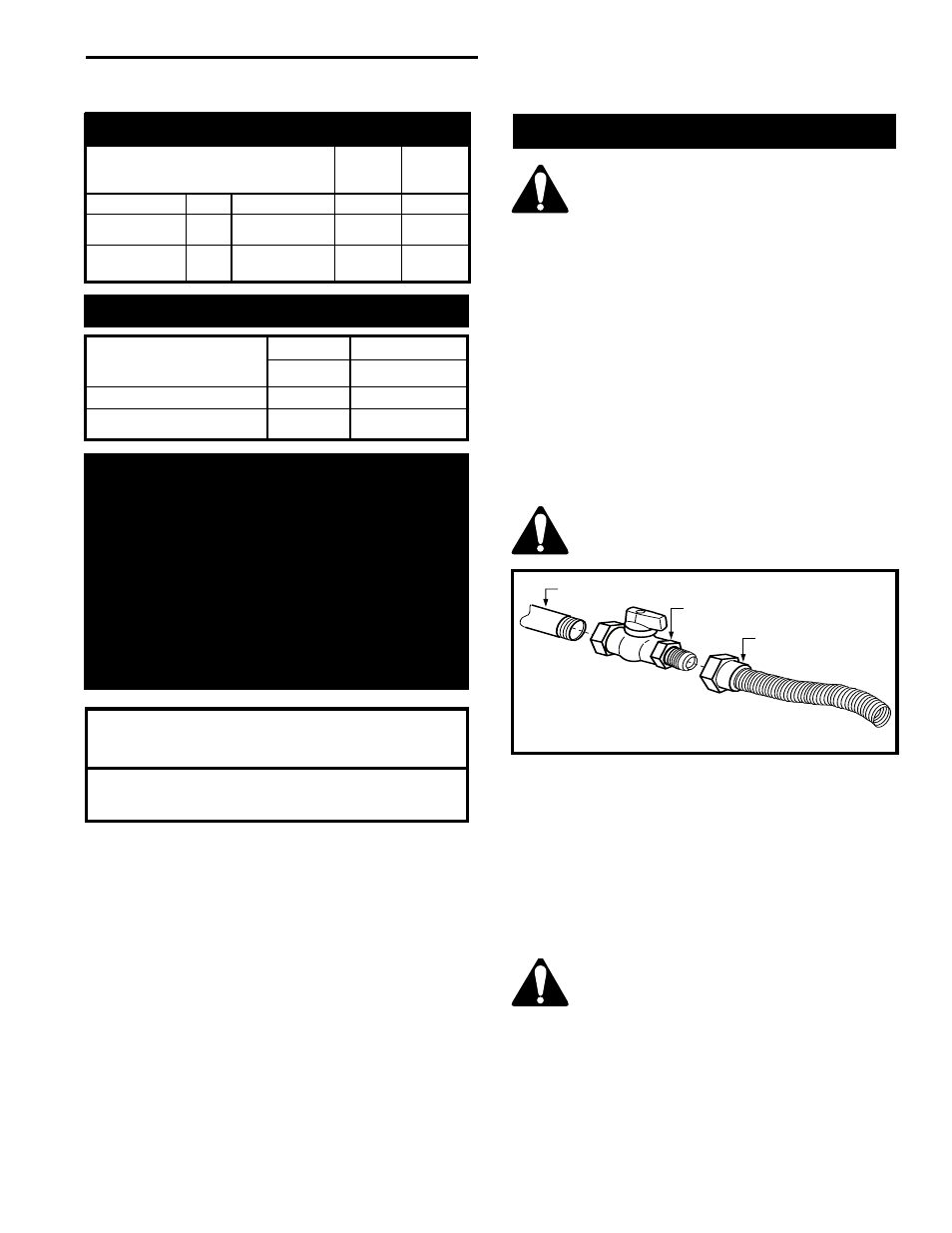

1/2” Gas Supply

1/2” NPT x 1/2” Flare

Shut-off Valve

3/8” Flex Line

(From Valve)

FP297a

Fig. 5 Typical gas supply installation.

The gas control is equipped with a captured screw type

pressure test point, therefore it is not necessary to

provide a 1/8" test point up stream of the control.

When using copper or flex connector use only ap-

proved fittings. Always provide a union when using

black iron pipe so the gas line can be easily discon-

nected for burner or fan servicing. Refer to the gas

specification for pressure details and ratings.

High Elevations

Input ratings are shown in BTU per hour and are

certified without deration for elevations up to

4,500 feet (1,370m) above sea level.

For elevations above 4,500 feet (1,370m) in USA,

installations must be in accordance with the

current ANSI Z223.1 and/or local codes having

jurisdiction.

In Canada, please consult provincial and/or local

authorities having jurisdiction for installations at

elevations above 4,500 feet (1,370m).