Vermont castings, majestic products dvrtsb, General information for connecting vent pipes, Termination clearances – Vermont Casting DVRTSB User Manual

Page 12: Crimped end pipes

12

Vermont Castings, Majestic Products DVRTSB

10003848

General Information for Connecting Vent Pipes

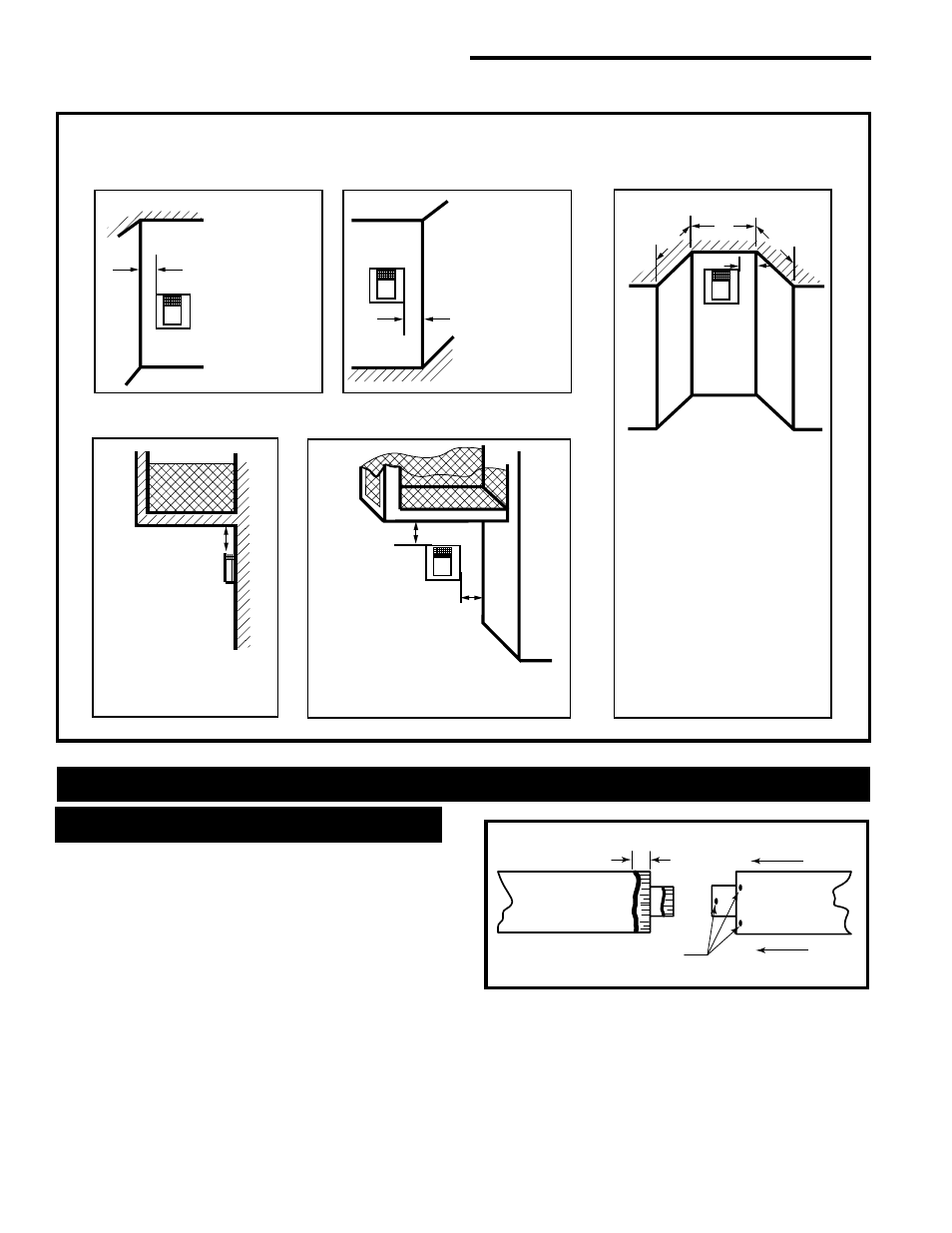

Outside Corner

Inside Corner

Termination Clearances

Termination clearances for buildings with combustible and noncombustible exteriors.

A =

Combustible

6"(152mm)

Noncombustible

2"(50mm)

B =

Combustible

6"(152mm)

Noncombustible

2"(50mm)

A

Balcony -

with no side wall

G =

Combustible &

Noncombustible

12"(305mm)

G

Balcony -

with perpendicular side wall

H = 24"(610mm)

J = 20"(508mm)

H

J

B

Recessed Location

C = Maximum depth of 48"

(1219mm) for recessed

location.

D = Minimum width for back wall

of a recessed location.

Combustible 38"(965mm)

Noncombustible 24"(610mm)

E = Clearance from corner in

recessed location.

Combustible 6"(152mm)

Noncombustible 2"(50mm)

C

D

C

E

V

V

Combustible &

Noncombustible

V

V

V

584-15

Fig. 12 Termination clearances.

Crimped End Pipes

Before joining elbows and pipes apply a bead of high

temperature sealant to the crimped end of the elbow or

pipe. Join the pipes using a 2” (50mm) overlap and

secure the joints with three (3) sheet metal screws.

(Fig. 13) Wipe off excess sealant.

Canadian Installations:

Venting system must be installed in accordance with

the current CSA-B149.1 installation code.

USA Installations:

The venting system must conform with local codes and/

or the current National Fuel Gas code ANSI Z223.1.

Only direct vent components manufactured by Vermont

Castings, Majestic Products can be used in Direct Vent

systems.

1" (25mm)

Screw Holes

FP1175

Fig. 13 Apply a bead of high temperature sealant.