Vermont castings, majestic products dvrtsb, Vertical sidewall applications, Rear wall vent installation – Vermont Casting DVRTSB User Manual

Page 14

14

Vermont Castings, Majestic Products DVRTSB

10003848

STEP 3

Measure the horizontal length requirement for the

venting including a 2” (50mm) overlap, i.e. from the

elbow to the outside wall face plus 2” (50mm) (or the

distance required if installing a second 90

°

elbow. (Fig.

17)

STEP 4

Install the 4” (100mm) vent to the appliance collar and

secure with three (3) sheetmetal screws. Install the 7”

(175mm) vent pipe to the appliance collar and secure

with three (3) sheet metal screws. It is not necessary to

seal this connection.

It is critical that there is no downward

slope away from the appliance when

connecting the vent or elbow.

STEP 5

Guide the vent through the vent hole as you place the

appliance in its installed position. Guide the 4”

(100mm) and 7” (175mm) collars of the vent termina-

tion into the outer ends of the venting. Do not force the

termination. If the vent pipes do not align with the

temination remove and realign the venting at the

appliance flue collars. Attach the termination to the wall

as outlined in the instruction sheet supplied with the

termination.

Vertical Sidewall Applications

20"

(508 mm)

FP1379

Fig. 16 Rear vent application, no elbows.

Rear Wall Vent Installation

STEP 1

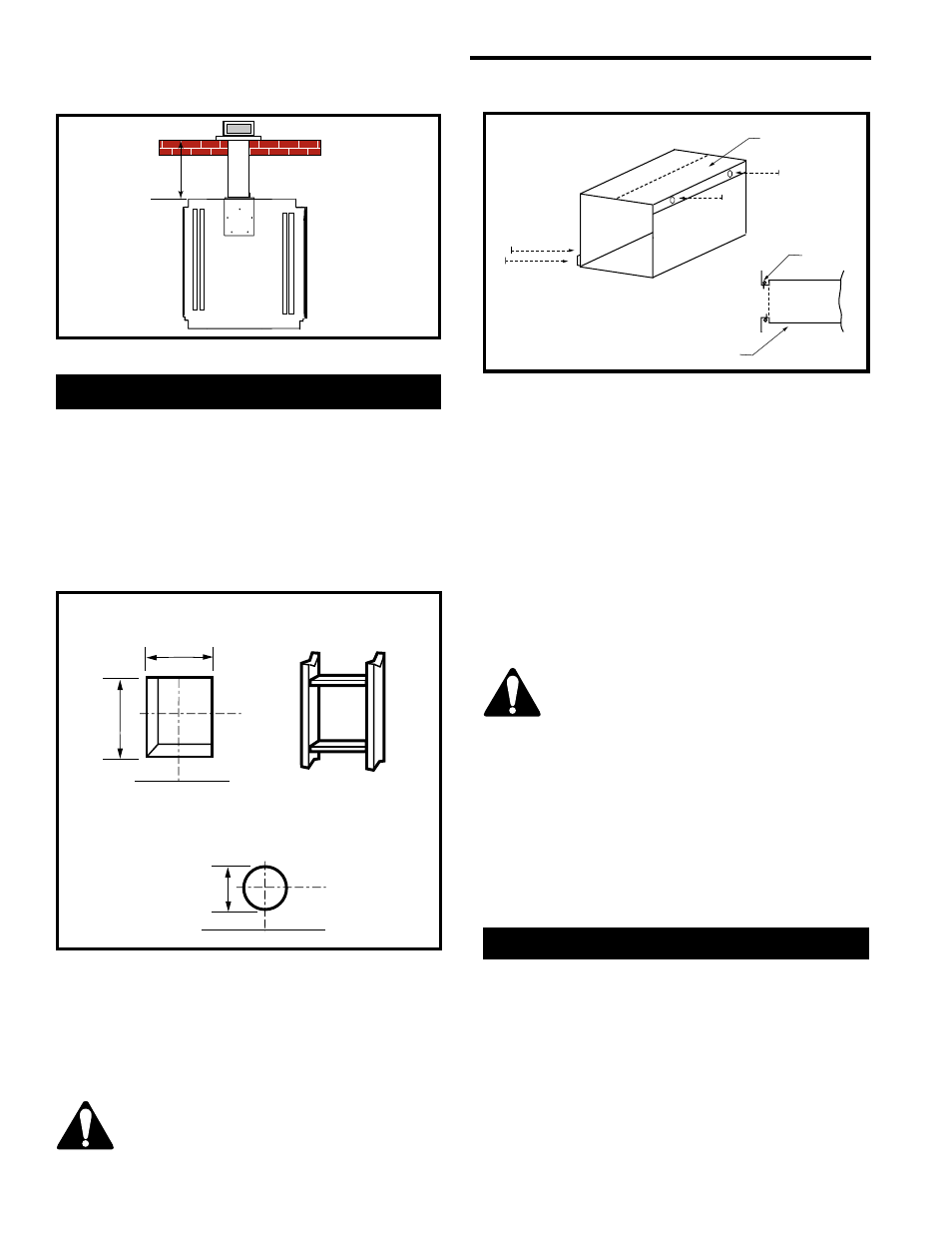

Locate and cut the vent opening in the wall. (Fig. 17)

For combustible walls first frame in opening. ( Fig. 17)

Combustible Walls: Cut a 10

³⁄₈

”H x 9

³⁄₈

” W (265 x

240mm) hole through the exterior wall and frame.

(Fig.21)

Noncombustible Walls: Hole opening must be 7

¹⁄₂

”

(190 mm) in diameter.

Vent Opening for Combustible Wall

9

³⁄₈

”

(240mm)

10

³⁄₈

”

(265mm)

Framing Detail

Opening for Noncombustible Wall

7

¹⁄₂

”

(190mm)

VO584-100

Fig. 17 Locate vent opening on wall.

STEP 2

Measure wall thickness and cut zero clearance sleeve

parts to proper length (MAXIMUM 12”/305mm). As-

semble sleeve to its maximum opening (10

³⁄₈

” x 9

³⁄₈

”)

and attach to firestop with #8 sheet metal screws

(supplied). Install firestop assembly. (Fig. 18)

Zero clearance sleeve is only required

for combustible walls.

Max. Length 12”

(305mm)

#8 Screws (2)

#8 Screws

(2)

Adjustable Zero Clearance Sleeve

ZCS101

#8 Screws (2)

Firestop

Adjustable Zero

Clearance Sleeve

Fig. 18 Adjustable zero clearance sleeve.

Since it is very important the venting system maintain

its balance between the combustion air intake and the

flue gas exhaust, certain limitations as to vent configu-

rations apply and must be strictly adhered to.

The vent graph showing the relationship between

vertical and horizontal side wall venting will help to

determine the various dimensions allowable.