Vermont castings, majestic products dvrtsb, Twist lock pipes – Vermont Casting DVRTSB User Manual

Page 13

13

Vermont Castings, Majestic Products DVRTSB

10003848

Twist Lock Pipes

When using Vermont Castings, Majestic Products

twist-lock pipe it is not necessary to use sealant on the

joints. The only areas of the venting system that need

to be sealed with high temperature silicone sealant

are the collars on the fireplace and termination, and

the sliding joint of any telescopic vent section used in

the system.

To join the twist lock pipes together, simply align the

beads of the male end with the grooves of the female

end, twisting the pipe until the flange on the female

end contacts the external flange on the male end. It is

recommended that you secure the joints with three (3)

sheet metal screws, however this is not mandatory with

twist lock pipe.

To make it easier to assemble the joints we suggest

putting a lubricant (Vaseline or similar) on the male

end of the twist lock pipe prior to assembly.

Male End

Female End

Screw Holes

TWL100

Fig. 14 Twist-lock pipe joints.

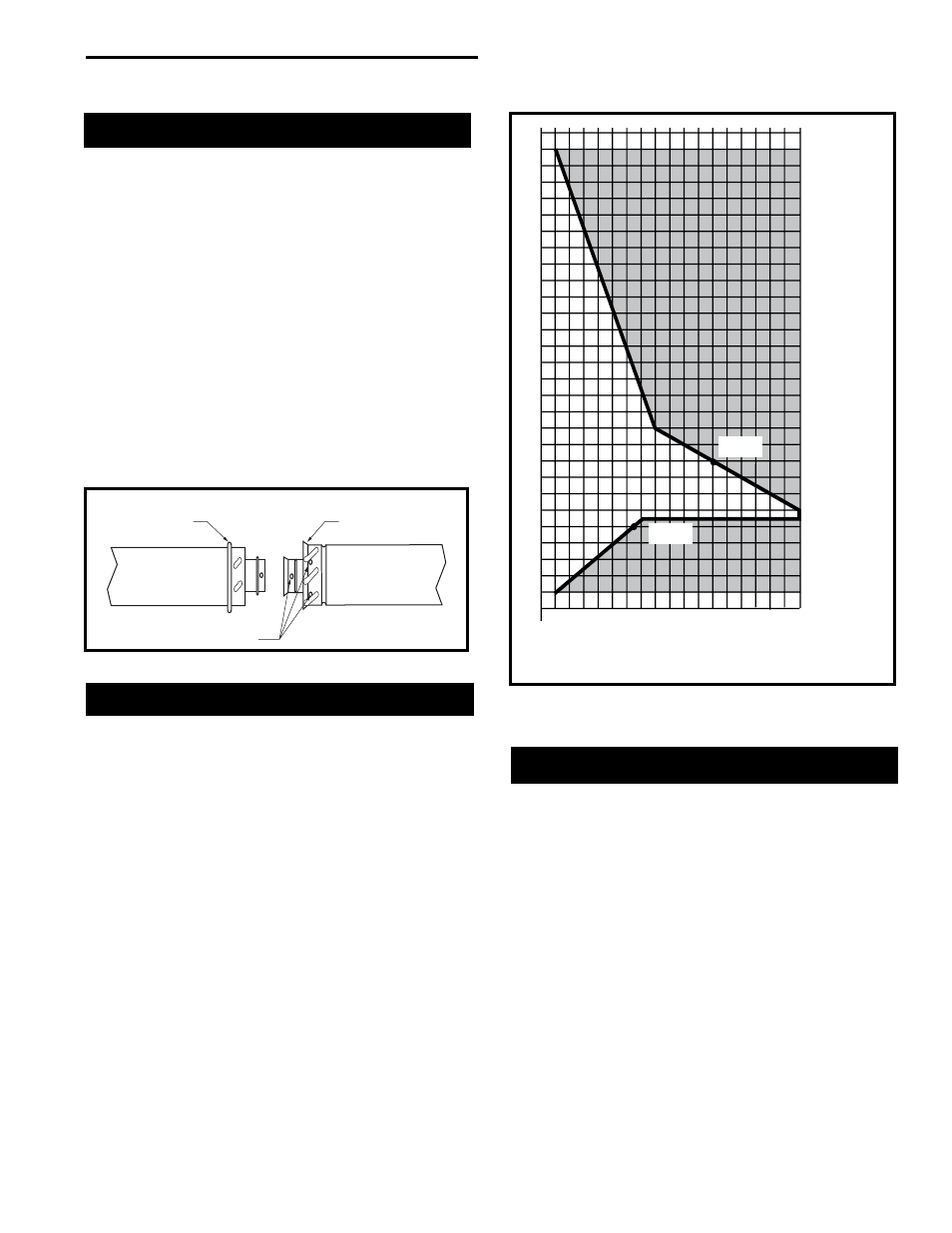

The vent chart should be read in conjunction with the

following vent installation instructions to determine the

relationship of the vertical and horizontal dimensions of

the vent system.

1. Determine the height of the center of the horizontal

vent pipe exiting through the outer wall. Using this

dimension on the Sidewall Vent Graph, (Fig. 15)

locate the point intersecting with slanted graph line.

2. From the point of this intersection, draw a vertical

line to the bottom of the graph.

3. Select the indicated dimension, and position the

fireplace in accordance with same.

Example A:

If the vertical dimension from the floor of the

fireplace is 11’ (3.4m) the horizontal run to the face

of the outer wall must not exceed 14’ (4.3m).

Example B:

If the vertical dimension from the floor of the unit is

7’ (2.14m), the horizontal run to the face of the outer

wall must not exceed 8

¹⁄₂

’ (2.6m).

How to Use the Vent Graph

Rear Wall Vent Application

When installed as a rear vent unit this appliance may

be vented directly to a termination located on the rear

wall behind the appliance.

•

Specific rear vent starter kits must be used in these

applications (see ‘Venting Components’). Theappli-

ance has been approved for installation flat against

a rear wall. (Fig. 16)

•

The maximum horizontal distance between the rear

of the appliance and the outside face of the rear wall

is 20” (508mm). (Fig. 16)

•

The minimum clearances between any combustible

material and the vent pipe sections are:

Top .................................................... 2” (50 mm)

Sides .................................................. 1” (25 mm)

Bottom ............................................... 1” (25 mm)

When the vent termination is installed in an accessible

location, a Screen Guard Kit, item #7V1B60, should be

installed. (Accessible means the termination is likely to

be touched)

Horizontal dimension from the outside face of the wall

to the center of the fireplace vent flange

Vertical dimension from the floor of the unit

To the center of the horizontal vent pipe

CFM102

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

eg: A

eg: B

Fig. 15 Sidewall vent graph showing the relationship be-

tween vertical and horizontal dimensions for a Direct Vent flue

system.