Vermont castings, majestic products dvrtsb, Below grade installations – Vermont Casting DVRTSB User Manual

Page 17

17

Vermont Castings, Majestic Products DVRTSB

10003848

X

X

FP1385

Fig. 26 Horizontal length requirement.

STEP 7

Apply high temperature sealant to 4” (100mm) and 7”

(175mm) collars or the termination one inch away from

crimped end. Guide the vent terminations 4” and 7”

collars into their respective vent pipes. Double check

that the vent pipes overlap the collars by 2” (50mm).

Secure the termination to the wall with screws provided

and caulk around the wall plate to weatherproof.

Support the horizontal pipes every 36” (914mm)

with metal pipe straps.

Check the fireplace to make sure that it is levelled

and properly positioned.

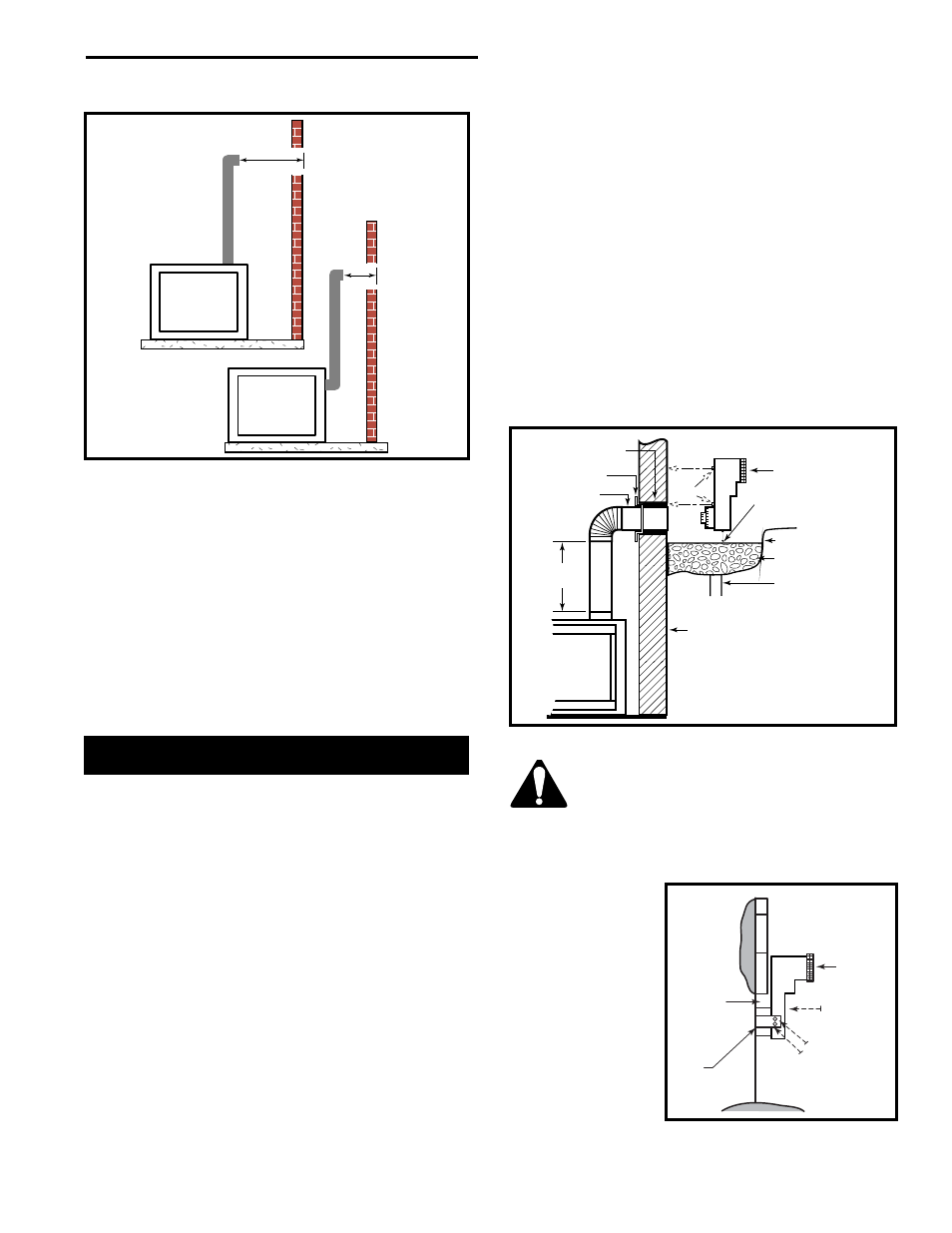

Below Grade Installations

When it is not possible to meet the required vent

terminal clearances of 12” (305mm) above grade level

a starter kit is recommended. It allows installation depth

of down to 7” (178mm) below grade level. The 7”

(178mm) is measured from the center of the horizontal

vent pipe as it penetrates through the wall.

If venting system is installed below ground, we recom-

mend a window well with adequate and proper drain-

age.

Ensure sidewall venting clearances are observed.

If installing a snorkel, a minimum 24” (610mm) vertical

rise is necessary. The maximum horizontal run with the

24” (610mm) vertical pipe is 36” (914mm). The meas-

urement is taken from the collar of the fireplace (or

transition elbow) to the face of the exterior wall. See

Vent Chart (see ‘How to use the Vent Graph’) for

extended horizontal runs if the vertical exceeds 24”

(610mm).

1. Establish vent hole through the wall. (Fig. 23)

2. Remove soil to a depth of approximately 16"

(406mm) below base of snorkel. Install drain pipe.

Install window well (not supplied). Refill hole with 12"

(305mm) of coarse gravel leaving a clearance of

approximately 4" (100mm) below snorkel. (Fig. 27)

3. Install vent system.

4. Ensure a watertight seal is made around the vent

pipe coming through the wall.

5. Apply high temperature sealant caulking (supplied)

around the 4” and 7” snorkel collars.

6. Slide the snorkel into the vent pipes and secure to

the wall.

7. Level the soil so as to maintain a 4” (100mm) clear-

ance below snorkel. (Fig. 27)

Zero Clearance

Sleeve if Required

Firestop

7” Pipe

7DVSKS

(Snorkel)

Screws

Minimum 4” Clearance

Ground

Window Well

Gravel

Drain

Foundation Wall

•

A minimum of 24” (610mm) vertical

pipe must be installed when using

the 7DVSKS/7TDVSKS kit.

•

The 22” vertical rise (center to

center) of the snorkel may be

included for calculation of max.

horizontal run.

24” (610mm)

Minimum

FP1386

Fig. 27 Below grade installation.

Do not back fill around snorkel.

A clearance of at least 4” (100mm) must

be maintained between the snorkel and

the soil.

If the foundation is recessed, use recess brackets (not

supplied) for

securing lower

portion of the

snorkel. Fasten

brackets to wall first,

then secure to

snorkel with self

drilling #8 x 1/2

sheetmetal screws.

It will be necessary

to extend vent pipes

out as far as

protruding wall face.

(Fig. 28)

Snorkel

Wall

Screws

Sheet Metal

Screws

Watertight

Seal

Around

Pipe

Foundation

Recess

CFM139

Fig. 28 Snorkel installatin, recessed

foundation.