Carrier 62E User Manual

Page 37

37

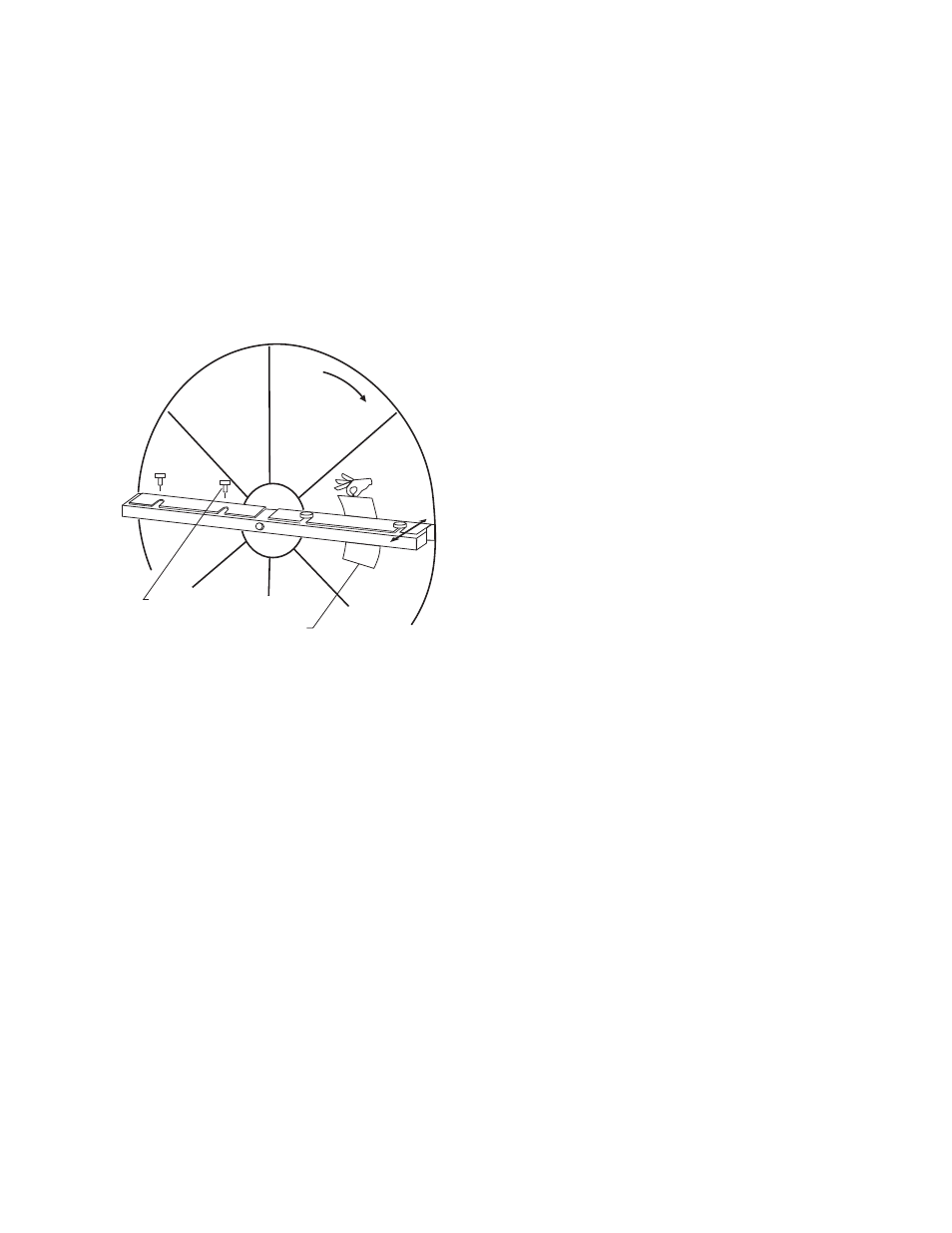

as a feeler gage, position paper between the wheel surface and

diameter seals. Adjust seals towards wheel surface until a slight

friction on the feeler gage (paper) is detected when gage is

moved along the length of the spoke. Retighten adjusting

screws and recheck clearance with “feeler” gage.

Wheel Drive Components —

The wheel drive motor

bearings are pre-lubricated and no further lubrication is neces-

sary. Make certain air cooling ports are not blocked.

The wheel drive pulley is secured to the drive motor shaft

by a setscrew. The setscrew is secured with removable adhe-

sive to prevent loosening. Annually confirm setscrew is secure.

The wheel drive belt is a urethane stretch belt designed to

provide constant tension through the life of the belt. No adjust-

ment is required. Inspect the drive belt annually for proper

tracking and tension. A properly tensioned belt will turn

the wheel immediately after power is applied with no visible

slippage during start-up.

Air Filters —

With this ERV unit and with most other

forced air heating, cooling and ventilation systems, regular air

filter maintenance is of utmost importance. Proper filter main-

tenance will improve indoor air quality, keep the building air-

handling system clean for peak efficiency, and prolong the life

of the HVAC (Heating, Ventilation, and Air Conditioning)

equipment. The life of the air filters is directly related to the ap-

plication to which the ERV unit is installed. The air filters

should be inspected every couple of weeks until a maintenance

schedule is established. The ERV unit is equipped from the fac-

tory with throwaway filters, however if the installer changed

the filter type, consult the installer for filter maintenance

instructions.

Replacing the Throwaway Filters —

After remov-

ing the service door (see Removing the Service Door section)

remove the spacer plugs and pull the filters or filter racks out of

the cabinet. Replace the filters with the original equipment

manufacturer replacements or equivalents. Refer to Tables 1A

and 1B for filter sizes.

Rotation

To

Adjust

Adjusting Screws

Feeler Gage

Fig. 39 — Diameter Seal Adjustment

A62-286ef