Carrier 62E User Manual

Page 33

33

engages the notch at the end of the shaft when reinstalling

the wheel.

4. Pull the wheel straight off the shaft. Handle wheel with

care to prevent distorting of the wheel.

Removing and Installing Non-Segmented

Wheel for Cleaning (62ECC and 62E2C

Units) —

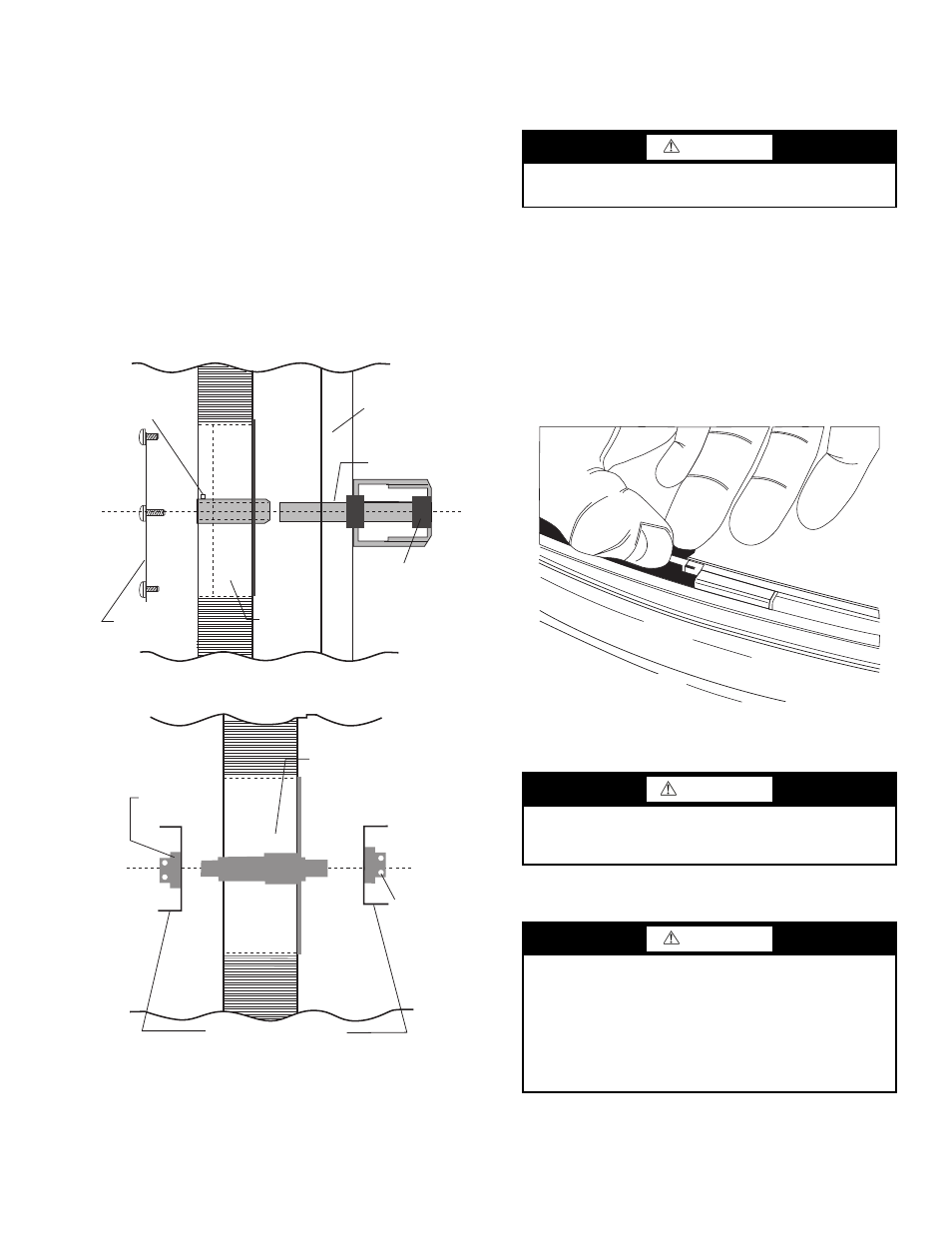

Non-segmented energy transfer wheels include

the shaft and are secured to 2 wheel support beams by 2 flange

bearings with locking collars. See Fig. 31.

To remove the energy transfer wheel, follow Steps 1-4

below. Reverse procedure for wheel installation.

1. Pull the wheel with shaft straight out of the motor side

wheel support beam and bearing. Handle wheel with care

to prevent distorting of the wheel.

2. Remove the pulley side wheel support beam with bearing

by removing the 4 support beam screws.

3. Remove the belt from the pulley and position temporarily

around the wheel rim.

4. Loosen the 2 set screws on each of the 2 wheel bearings.

See Fig. 31.

Removing Wheel Segments for Cleaning

(62ECD, 62ED-EU, 62E2D, and 62E3-E6 Units)

1. Unlock and open the segment retaining brackets on both

sides of the selected segment opening. Refer to Fig. 32.

2. Gently lift segment outward.

3. Close segment retaining latches and rotate wheel 180 de-

grees to remove next segment. Follow this pattern to

remove all segments. This pattern will help keep wheel

balanced.

To install the segments, see the Installing Wheel Segments

section.

Installing Wheel Segments

NOTE: Both installation and removal procedures must be per-

formed from the pulley side of the cassette.

Alignment

Pin

Cassette

Housing/Frame

Shaft

Bearings (2)

Hub Cover

Wheel &

Hub

Fig. 30 — 62EB and 62E7 Energy

Transfer Wheel Assembly

A62-279ef

FLANGE

BEARINGS

(2)

SET

SCREWS

(2) EACH

WHEEL,

HUB &

SHAFT

WHEEL SUPPORT BEAMS

Fig. 31 — 62ECC and 62E2C Energy

Transfer Wheel Assembly

CAUTION

When replacing wheel, retighten the 4 bearing set screws.

Premature bearing failure could result.

WARNING

Before performing service or maintenance operations on

unit, turn off main power switch to unit. Electrical shock

could cause personal injury.

CAUTION

Weight of the installed segment will cause the wheel to

accelerate in rotation. Failure to maintain control of the

wheel rotation while installing all segments could cause

severe injury to fingers or hand caught between revolving

spokes and the bearing support beam. Handle of hammer,

or other stop, should be inserted through spokes and above

or below bearing support beams to limit rotation of unbal-

anced wheel. See Fig. 33.

Fig. 32 — Unlocking the

Segment Retaining Brackets

A62-278ef