Carrier 62E User Manual

Page 34

34

NOTE: The 62EBA, 62EBC, 62ECC, 62E7A, 62E7C, and

62E2C units contain non-segmented wheels which must be

completely removed to be cleaned.

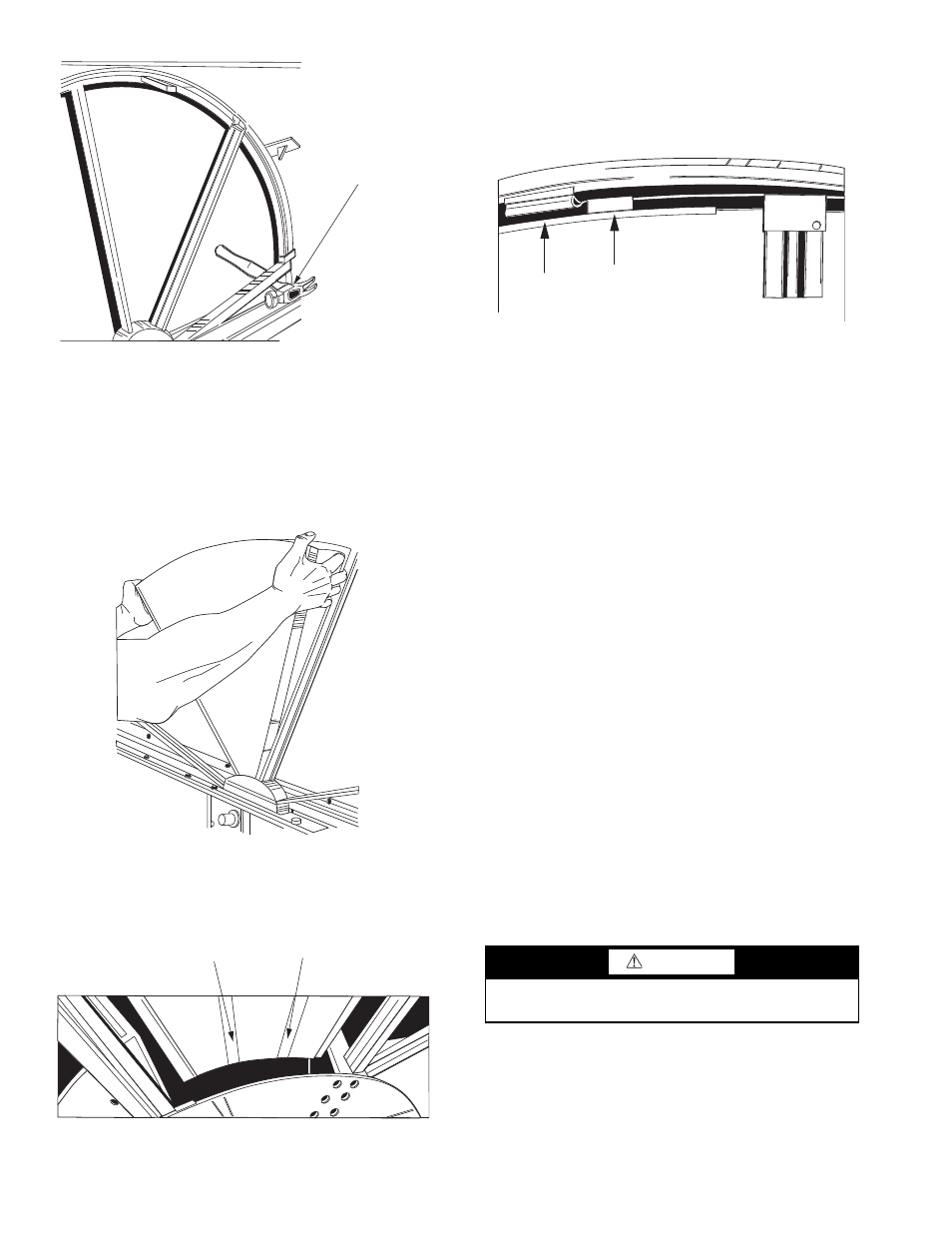

1. Begin by positioning one segment opening at the top of

the cassette. Unlock and open the segment retaining

brackets on both sides of the selected segment opening.

2. Holding the segment as vertical as possible and

centered between spokes, insert nose of segment down-

ward between the hub plates. See Fig. 34.

NOTE: The face of the segment, with the imbedded

stiffener (vertical support between nose and rim end of

segment) must face the motor side of the cassette. See

Fig. 35.

3. Ease the segment downward until its outer rim clears the

inside of the wheel rim. Then press the segment inward

against the spoke flanges.

4. Close and latch segment retaining brackets to the position

shown in Fig. 36. Make certain the retaining bracket is

fully engaged under the catch.

5. Slowly rotate, by hand, the first installed segment to the

bottom of the cassette, then install the second segment

opposite the first. Repeat this sequence with the 2 in-

stalled segments rotated to the horizontal position to bal-

ance the weight of installed segments. Continue this se-

quence with the remaining segments.

Wheel Drive Motor and Pulley Replacement

(62EC-EU and 62E2-E6 Units)

1. Disconnect power to wheel drive motor.

2. Remove belt from pulley and position temporarily around

wheel rim.

3. Loosen setscrew in wheel drive pulley using Allen

wrench and remove pulley from motor drive shaft.

4. While supporting weight of drive motor in one hand,

loosen and remove 4 mounting bolts.

5. Install replacement motor with hardware kit supplied.

6. Install pulley to dimension shown in Fig. 37 and secure

setscrew to drive shaft.

7. Stretch belt over pulley and engage in groove.

Belt Replacement

1. Obtain access to the pulley side bearing access plate.

Remove 2 bearing access plate retaining screws and the

access plate.

2. Using hexagonal wrench, loosen setscrew in bearing

locking collar. Using light hammer and drift (in drift pin

hole) tap collar in the direction of wheel rotation to

unlock collar. Remove collar.

3. Using socket wrench with extension, remove 2 nuts

which secure bearing housing to the bearing support

beam. Slide bearing from shaft.

NOTE: Slight hand pressure against wheel rim will lift weight

of wheel from inner race of bearing to assist bearing removal

and installation. If not removable by hand, use bearing puller.

4. Using a wrench, remove diameter seal retaining screws or

hub seal retaining screws. Remove diameter seals or hub

seal from bearing beam. See Fig. 38.

5. Form a small loop of belt and pass it through the hole in

the bearing support beam. Grasp the belt at the wheel hub

and pull the entire belt down. Loop the trailing end of the

belt over the shaft (Fig. 38 shows belt partially through

the opening).

HAMMER

USED AS

“STOP”

Fig. 33 — Using a Stop on the Wheel

A62-280ef

Fig. 34 — Inserting a Segment of the Wheel

A62-281ef

Imbedded Stiffeners

Fig. 35 — Motor Side View of Segment

A62-282ef

CAUTION

Protect hands and belt from possible sharp edges of hole in

bearing support beam.

CATCH

PULL TAB

Fig. 36 — Latch Segment Retaining Brackets

A62-283ef