Amico SSM Monitor Arms (Side to Side) User Manual

Page 27

www.amico.com

24

Area

Maintenance

Period (Month)

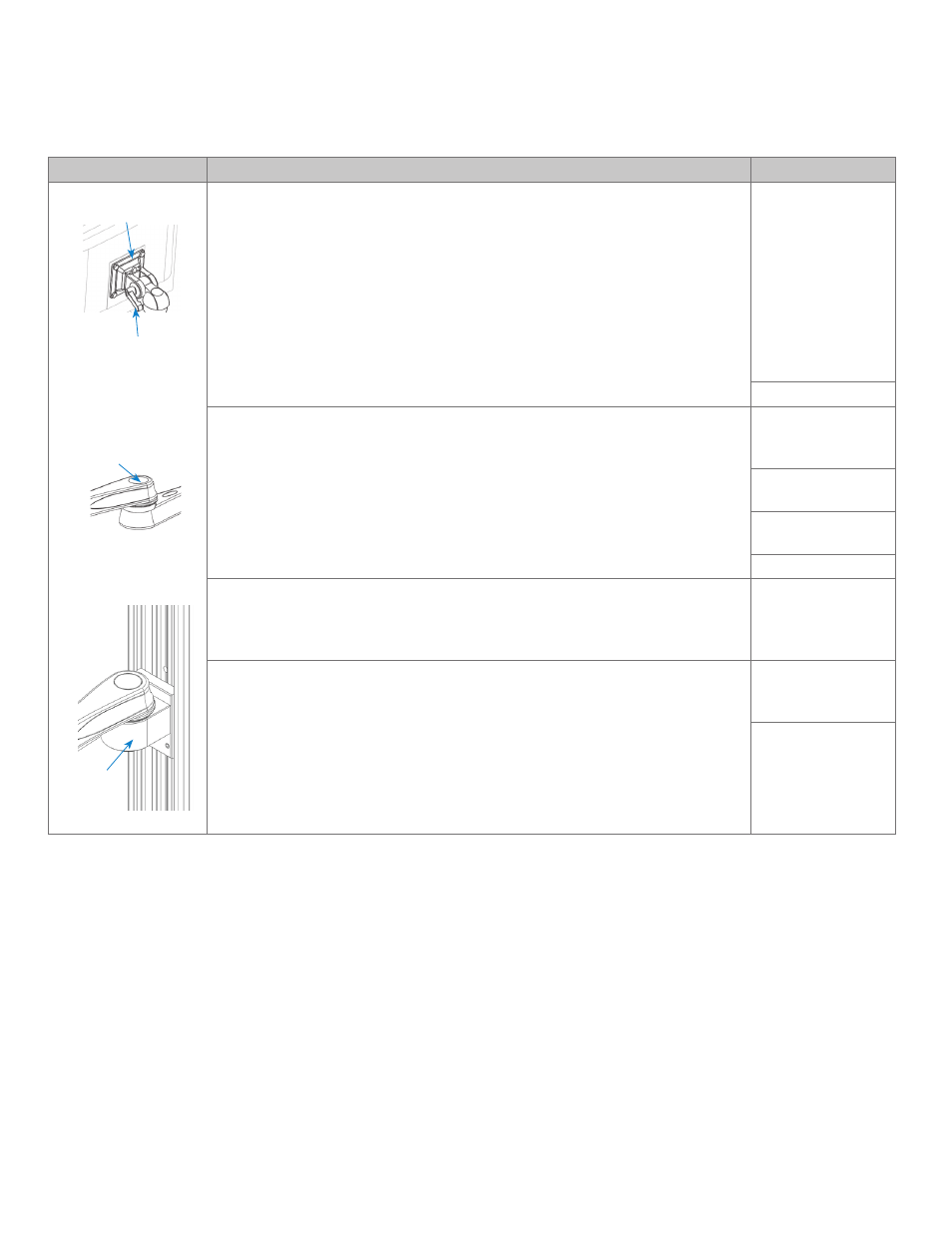

Area 1:

A) Check if the adapter plate and the monitor are securely attached.

• Mounting shelves & drop on shelf (SSM-XX (0, 2, 6, 8, and 9)) – Ensure the

screws are tight. Ensure the plunger is securely holding the adapter.

• VESA 75/100(SSM-LCD) – Ensure the four screws on the mounting plate are

fastened to the tightest possible position (shown).

• Philips (SSM-XX3) – Ensure studs are securely holding the monitor

• Welch Allyn (SSM-XXW) – Ensure the thumb screw is fastened to the tightest

possible position.

3

B) Visually inspect for any signs of grinding and gapping.

1

Area 2:

A) Ensure the adjustment lever is tight and secure. Also check if the plastic cover is

attached firmly. Tightening will be required after prolonged use.

1

B) Inspect the bolt, washers and contacting surfaces for grinding and wearing.

Ensure the bolt is tightened to the tightest position.

6

C) Check for any signs of gapping between the bushing and the head. Also ensure

the head of the SSM is horizontal and is secure.

6

D) Inspect the bolt, washers and contacting surfaces for grinding and wearing.

6

Area 3:

Ensure all the screws are fastened to the tightest possible position. Inspect for

any signs of grinding, bending and gapping and ensure the SSM arms are tightly

attached together.

1

Area 4:

A) Inspect the bolt, washers and contacting surfaces for grinding and wearing.

Ensure the bolt is tightened to the tightest position.

6

B) Inspect visually for any gapping between the bracket and the adapter plate.

Ensure the bracket is tightly attached to the adapter plate.

MRS and Hill-Rom – Ensure the screws are fastened to the tightest possible

position.

VRS – Ensure the screw knobs are fastened to the tightest possible position.

1

1

2

3

4

Section 5:

Maintenance, Troubleshooting and Product Classification