Drive-off unload, Drive-off unload steps – Great Plains NP30A 30-foot Predelivery Manual User Manual

Page 14

10

NP30 or NP40

Great Plains Manufacturing, Inc.

407-313Q

08/30/2011

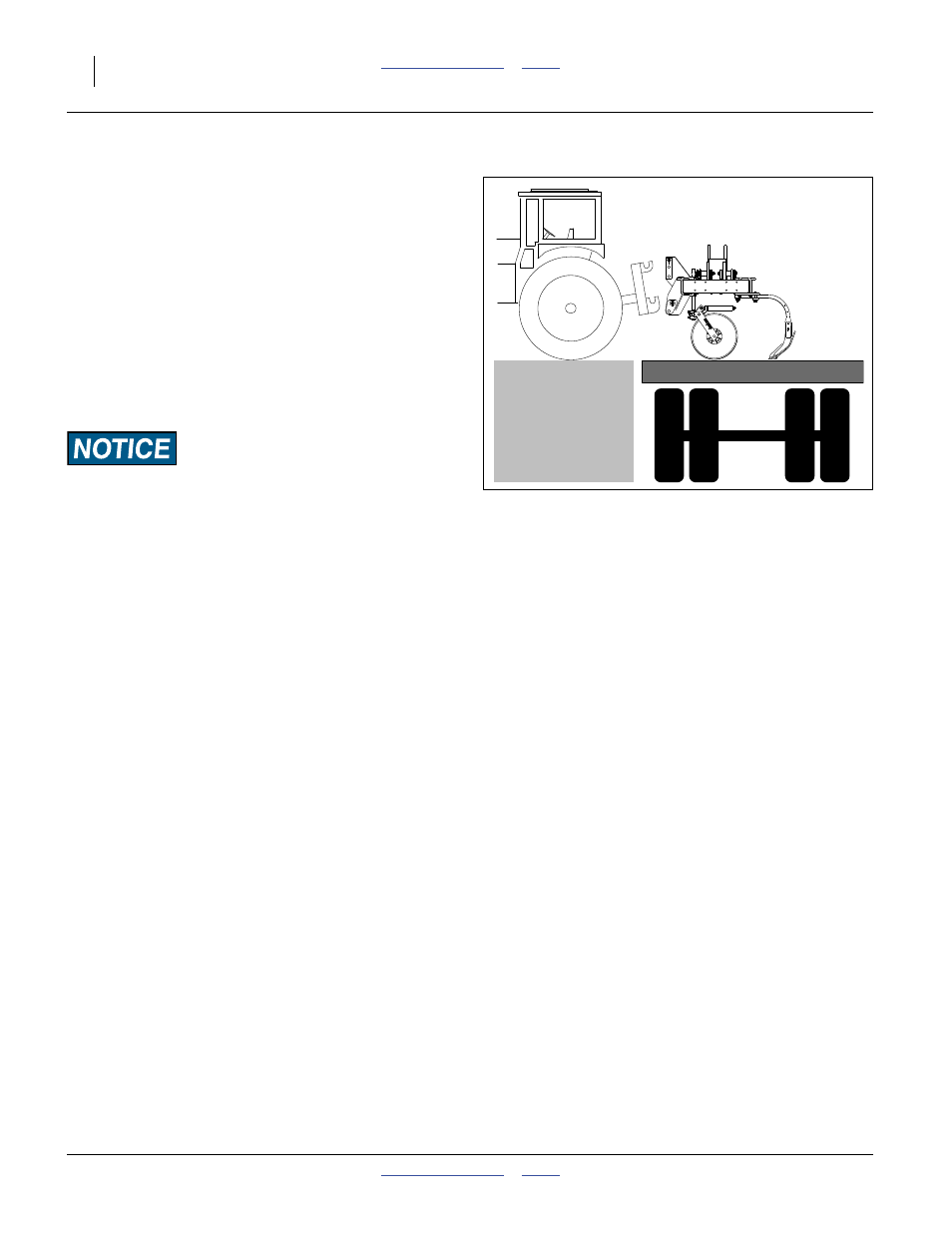

Drive-Off Unload

If a side dock or pit dock is available, all Nutri-Pro

®

imple-

ment configurations may be safely removed by a 3-point

tractor with adequate lifting capability.

The lift must be performed in full 3-point mode.

All implements (including Pull-Type) have suitable pins in

the lower holes of the hitch weldment.

2-Point and Pull-Type implements do not include a 1

1

⁄

4

in

hitch pin for the top hole. You need to provide this if drive-

off unload is desired.

On 2-Point and Pull-Type implements, do not attempt to

use the lift-assist circuit while the implement is on the

trailer bed. The lift-assist circuit may not be charged with

oil.

Machine Damage Risk:

On 2-Point implements, the lift-assist circuit is also intercon-

nected with the fold circuit. On 40-foot models, using lift-assist

on the trailer bed causes wing cylinder movement, which could

cause machine or trailer damage.

Note: The lift-assist caster assemblies are likely to settle

downward when the implement is lifted. This is nor-

mal, but they provide no support for the implement

during unload.

Drive-Off Unload Steps:

12. Hitch the tractor 3-point to the implement. See the

Operator manual (407-313M or 407-502M) for hitch-

ing details. Do not connect the hydraulics.

13. Support most of the weight of the implement with

the tractor hitch.

14. Release the straps or chains securing the imple-

ment to the trailer bed. Remove loose stands.

15. Pull the tractor forward.

16. Lower the implement onto its parking stands, or

other stands or supports.

Figure 13

3-Point Drive-Off

31692