Great Plains YP825A Operator Manual User Manual

Page 98

94

YP425A, YP625A and YP825A

Great Plains Manufacturing, Inc.

401-651M

2014-08-15

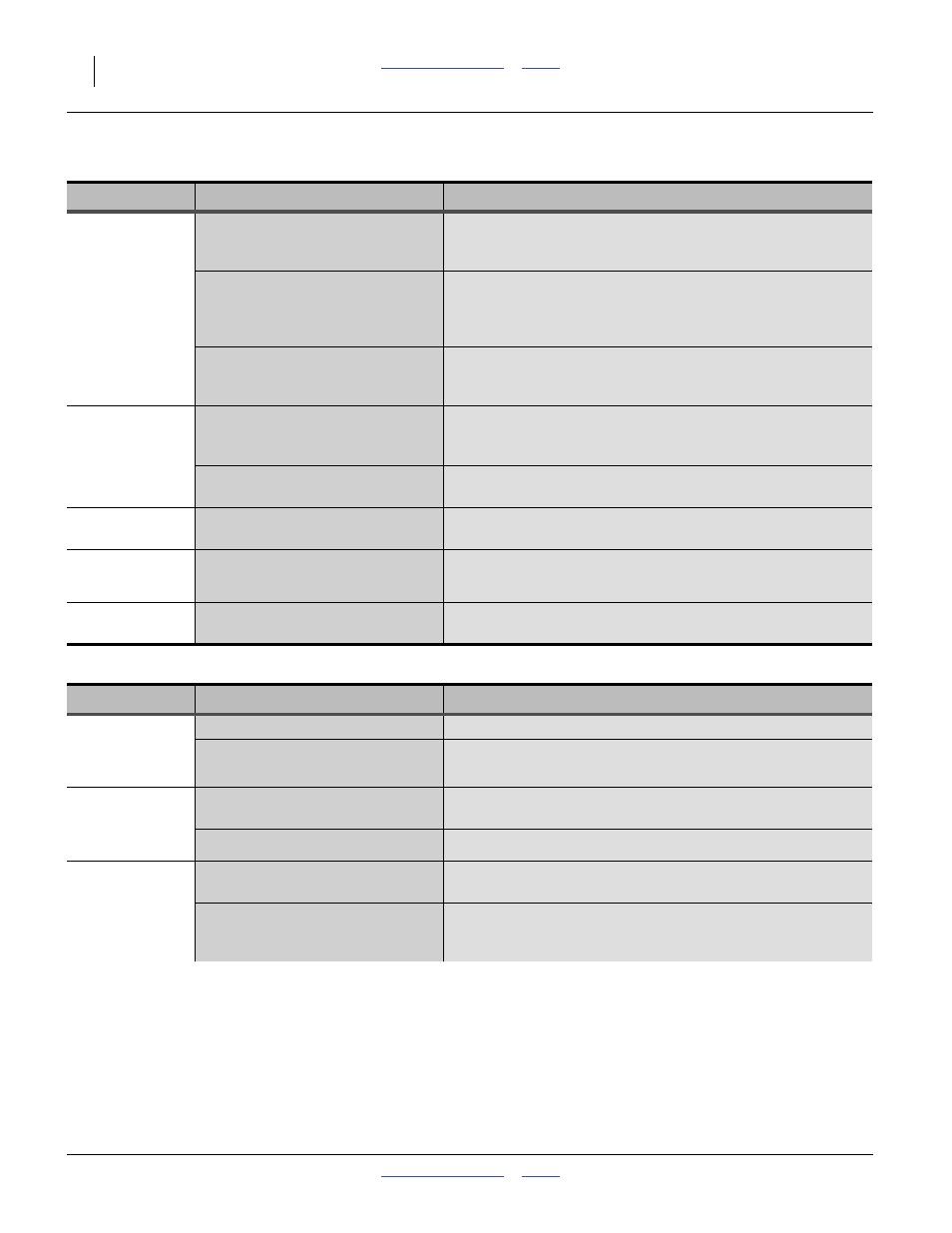

High Pressure, at

Desired Rate

Orifice size too small

Review orifice sizing. If at recommended size, try the next

large size. Charts are based on typical density/viscosity

materials.

Plugged nozzles

Inspect low-flow rows, or several nozzles. Clean plates.

Consider smaller strainer screen size and/or large orifice

plate size. Sedimentation, coagulation, particulates, foreign

matter can also cause unusually high pressure.

Orifice plates inverted

Orient plates with legends facing outlet. Orifice port holes are

not symmetrical, and at smaller sizes this can cause slightly

higher back-pressure with denser materials.

Very High

Flow

Fertilizer transmission in High

Range when Low Range was

intended.

Swap sprockets at transmission. See Seed and Fertilizer

Rate manual (401-651B).

Various possible pump issues

Pump Leaks

Various possible pump issues

Pump Oil

Consumption

Pump seals or O-ring

Noisy Pump

Crankcases components worn

Dry Fertilizer Troubleshooting

Problem

Cause

Solution

No Fertilizer

Flow, All

Rows

Hopper empty

Check / refill hopper.

Chain missing at one or more

drive stages

Check all five chains from ground drive to hoppers. See “Dry

Fertilizer Chains” on page 153.

No Fertilizer

Flow, Some

Rows

Hopper plugged

Clean out any material clogging discharge port. See “Dry

Fertilizer Clean-Out” on page 100.

Shaft disconnected

Check couplers along final drive shaft.

No Fertilizer

Flow, One

Row

Applicator tube plugged with soil

Disconnect hose at top of applicator tube. Remove blockage

from below. Raise release height (page 60).

Applicator tube plugged with

fertilizer.

Disconnect hose at top of applicator tube. Remove blockage

from below. Use finer grained fertilizer, or dry out the fertilizer

if coagulation is the problem.

Liquid Fertilizer Troubleshooting

Problem

Cause

Solution