Great Plains YP825A Operator Manual User Manual

Page 94

90

YP425A, YP625A and YP825A

Great Plains Manufacturing, Inc.

401-651M

2014-08-15

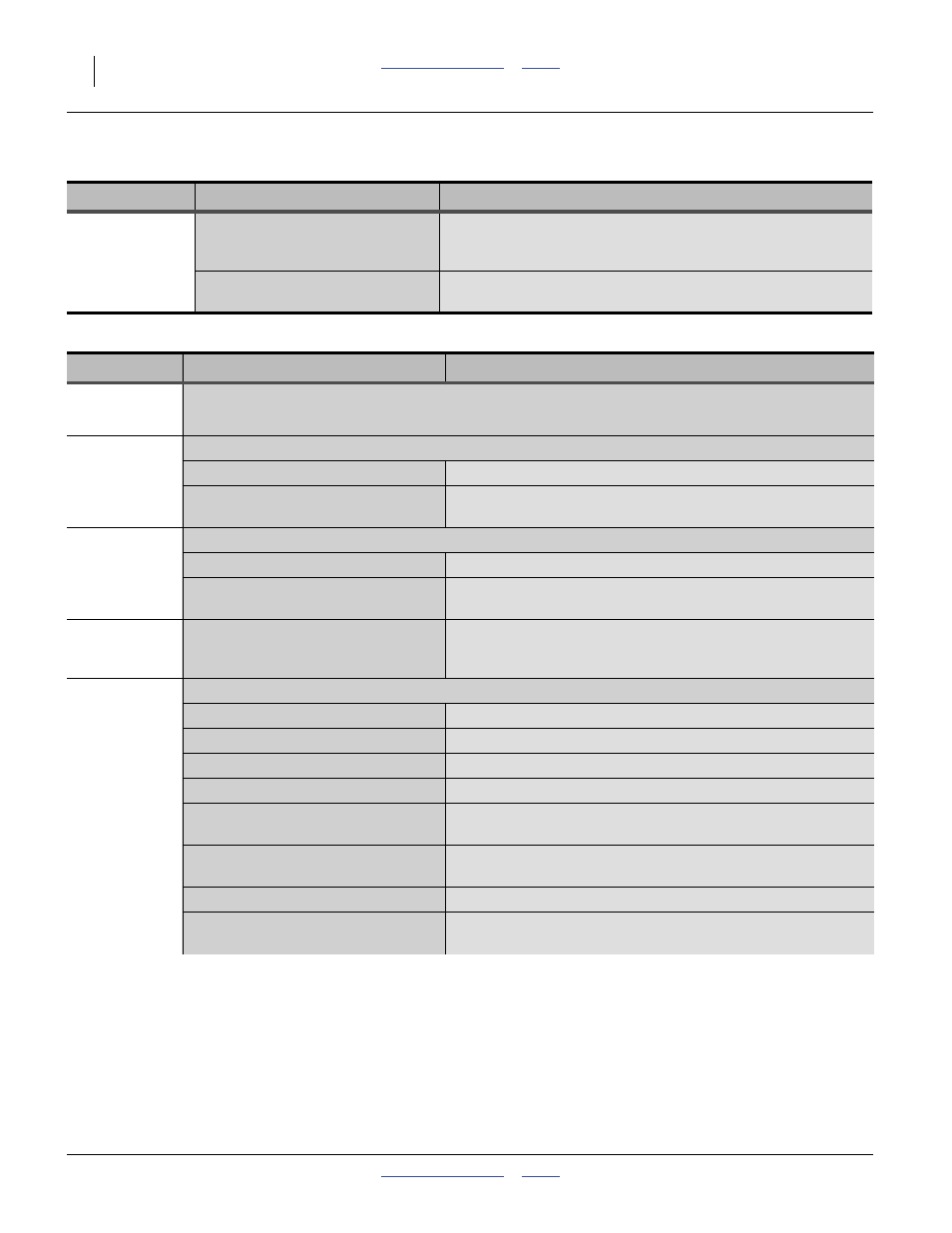

Twin Rows

were timed

but became

out of time.

Timing will change when a

population change has been

made.

Re-time meters from the population based timing chart.

Chain has jumped.

Check sprockets and chain for excessive wear or rusty stuck

links.

Population Related

Problem

Cause

Solution

General Troubleshooting

Problem

Cause

Solution

Population

Alarms

See “Population Troubleshooting Charts” on page 86.

Excess Seed

Remaining

See “Population Troubleshooting Charts” on page 86.

Field size different.

After ruling out population problems, re-check geography.

Excessive gaps between planter

passes.

Adjust marker, page 165.

Seed

Consumption

Too High

See “Population Troubleshooting Charts” on page 86.

Field size different.

After ruling out population problems, re-check geography.

Excessive overlap.

Irregular shaped field.

Adjust marker, page 165.

Rows Not

Planted

If not detected by optional seed

monitor, check for plugged row-unit

seed tube

Lift planter, expose bottom of seed tube and clean out.

Uneven

seed

spacing

See “Population Troubleshooting Charts” on page 86.

Excessive field speed.

Reduce field speed.

Unclean seed.

Use clean seed.

Damaged seed tube

Inspect; repair or replace.

Seed-Lok

®

plugging.

Lock up Seed-Lok

®

Row-unit discs not turning.

See “Row-unit discs not turning freely” in this

Troubleshooting chart.

Worn/rusted sprockets and/or chain

idler or bearings.

Check and replace any worn/rusted sprockets or chain idlers.

Partially plugged row-unit seed tube. Lift up planter, expose bottom of seed tube and clean out.

Lack of proper seed lubrication on

seed.