Great Plains YP825A Operator Manual User Manual

Page 97

Great Plains Manufacturing, Inc.

Troubleshooting

93

2014-08-15

401-651M

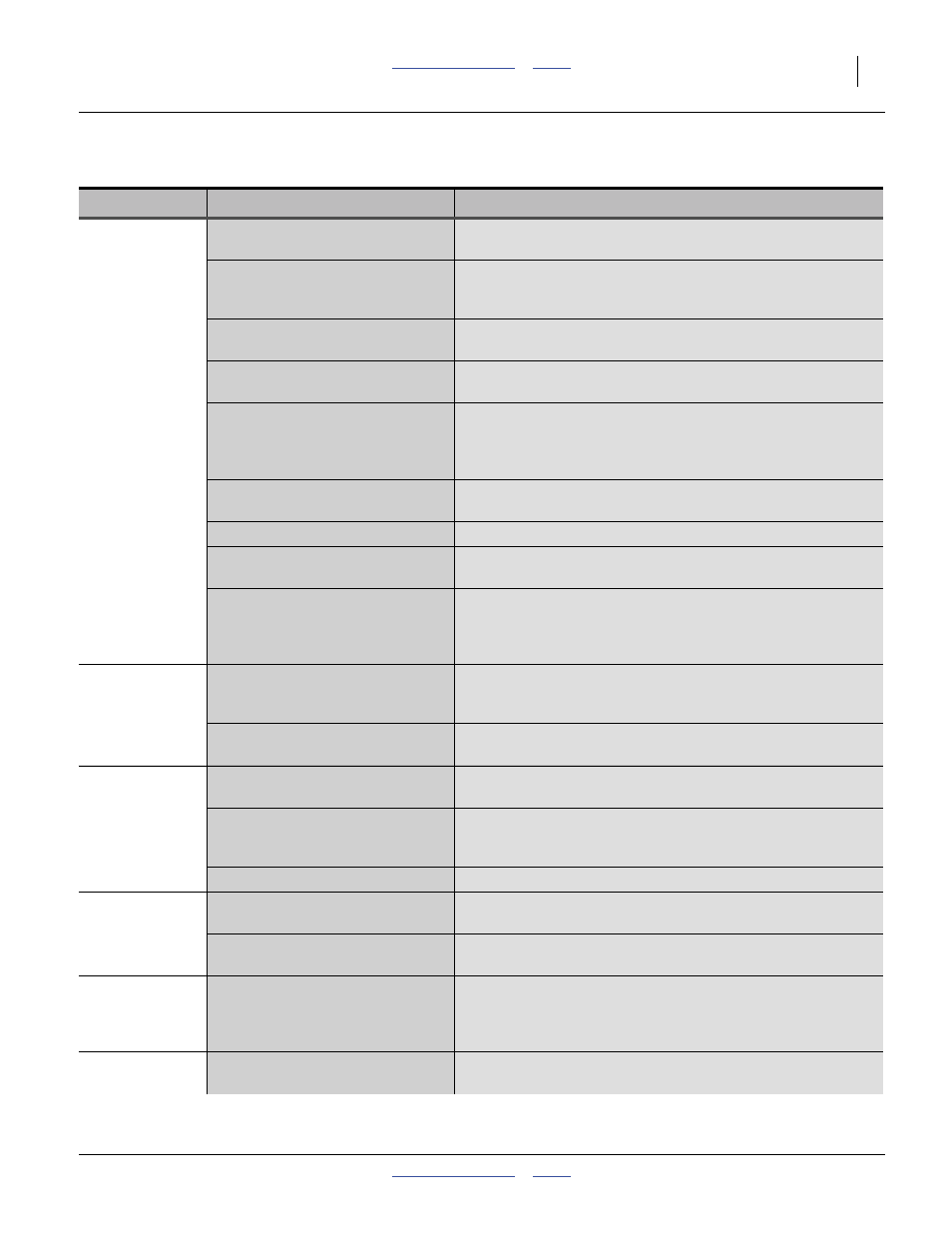

Liquid Fertilizer Troubleshooting

Problem

Cause

Solution

No Fertilizer

Flow

Various possible pump issues

Refer to Trouble Chart in CDS-JohnBlue LM-1250/LM-1255

Parts and Instruction manual, part number 12-M-15.

Discharge and/or main selector

valve closed

Check that discharge valves are open to selector valve, and

selector valve is open to pump. See “Liquid Fertilizer

Operation (Option)” on page 35

Chain missing at one or more

drive stages

Check all five chains from ground drive to pump. See “Chain

Routing” on page 147.

Tank plugged

Dilute or clean out any material clogging discharge port. See

“Liquid Fertilizer Clean-Out” on page 99.

Strainer plugged

Close all valves. Inspect strainer (See Seed and Fertilizer

Rate manual (401-651B)). Clean screen as needed. Switch

to a larger screen size if materials clog strainer rapidly (and

large size orifices are in use).

Pump setting at or near zero

Recommended pump adjuster settings are in the range

2 to 10. See Seed and Fertilizer Rate manual (401-651B).

Material run-out

Check tank level.

Material merely low - loss of prime Add material. When tank level is below pump inlet level, any

air allowed in the line can cause the pump to lose prime.

Air in pump due to slope (two-tank

system)

Add material, meter from one tank at a time, or close empty

tank. When planting across a slope, material can flow from

one tank to the other. If an empty tank is open to the pump,

the pump will cavitate and not meter fertilizer.

Low Rate

Fertilizer transmission in Low

Range when High Range was

intended.

Swap sprockets at transmission. See Seed and Fertilizer

Rate manual (401-651B).

Various possible pump issues

Low Pressure, at

Desired Rate

Orifice size too large

Choose alternate orifice plate size based on charts in Seed

and Fertilizer Rate manual (401-651B).

Orifices correct plate call size, but

their holes are enlarged from

extended use

Obtain new plates in the desired size. Discard worn plates.

Rate may actually be low

Check fertilizer transmission Driving/Driven sprockets.

Uneven Flow, at

Desired Rate

One or more orifice plates plugged Clean and re-installed orifice plates. Check that materials are

not too viscous or granular for the orifice size.

Plate sizes vary between rows

Check that all nozzles have the same size plates (with the

possible exception of outside rows serving zone coulters).

Pressure

Unstable

Strainer clogged

Dumping at

Normal Pressure

Relief valve setting too low

Review relief valve setting per Seed and Fertilizer Rate

manual (401-651B).