Press wheel centering – Great Plains YP825A Operator Manual User Manual

Page 86

82

YP425A, YP625A and YP825A

Great Plains Manufacturing, Inc.

401-651M

2014-08-15

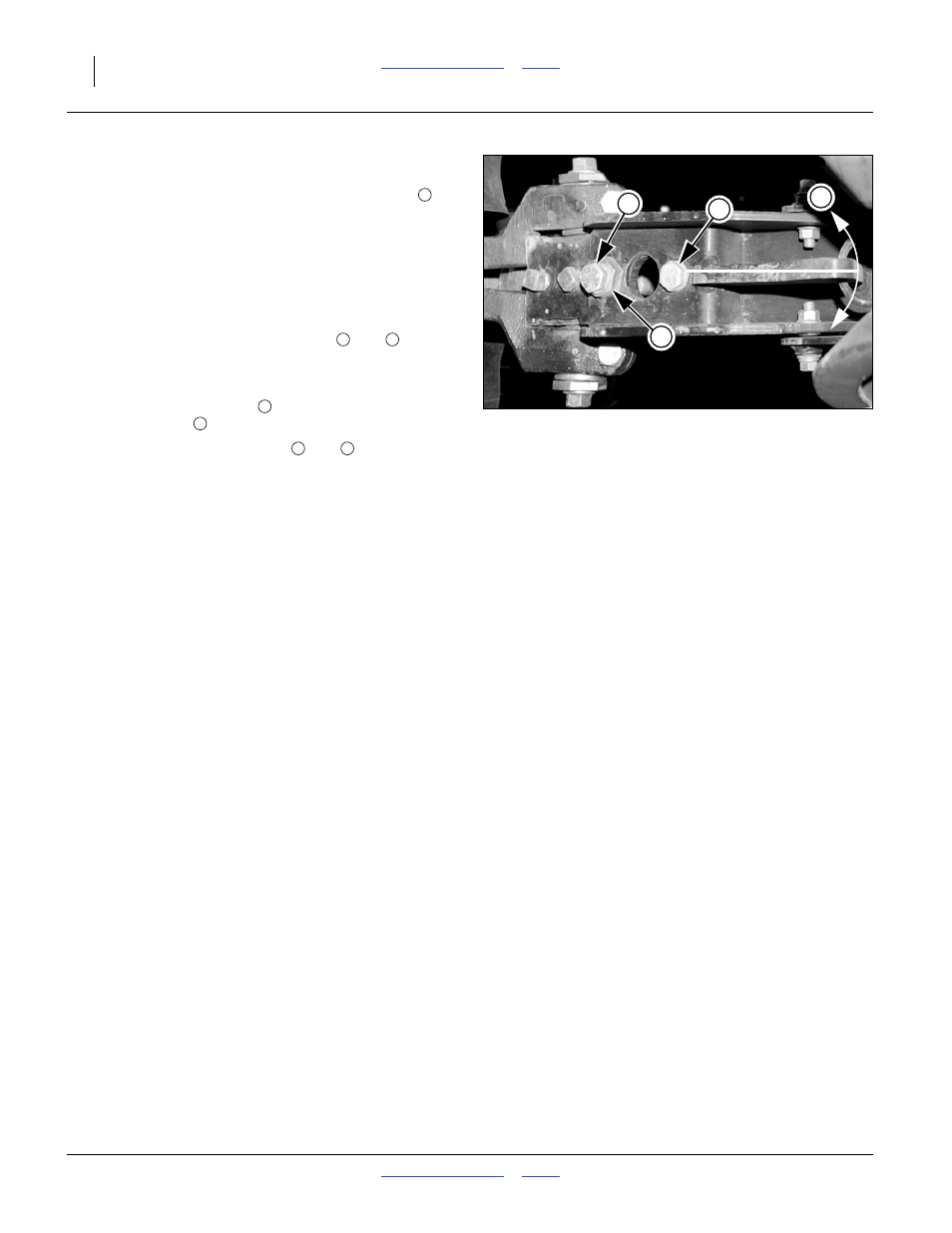

Press Wheel Centering

If one press wheel is running in the seed trench, or the

wheels are not centered over the trench, the angle

of

the press wheel assembly can be adjusted as follows:

Refer to Figure 103

1.

Determine how far, and in which direction, the press

wheel assembly needs to move to center the wheels.

2.

Raise planter and install lift assist cylinder locks. See

“Lift Cylinder Locks (SN-)” on page 23.

3.

Loosen the

1

⁄

2

inch hex-head bolts

and

.

Note: Do not loosen the square-head bolts forward of the

hex-head bolts.

4.

Turn the hex head cam

under the forward hex

head jam bolt

, and move the required amount.

5.

Tighten both hex head bolts

and

.

If press wheel adjustments do not provide satisfactory

furrow closing, your conditions may require alternate

press wheels. A variety of wheel assemblies are

available. Consult your Great Plains dealer.

Figure 103

Press Wheel Centering

(View from beneath opener)

25277

3

2

1

4

1

2

3

4

3

2

3