Great Plains 3N-4025P Operator Manual User Manual

Page 67

4/23/2010

196-286M

65

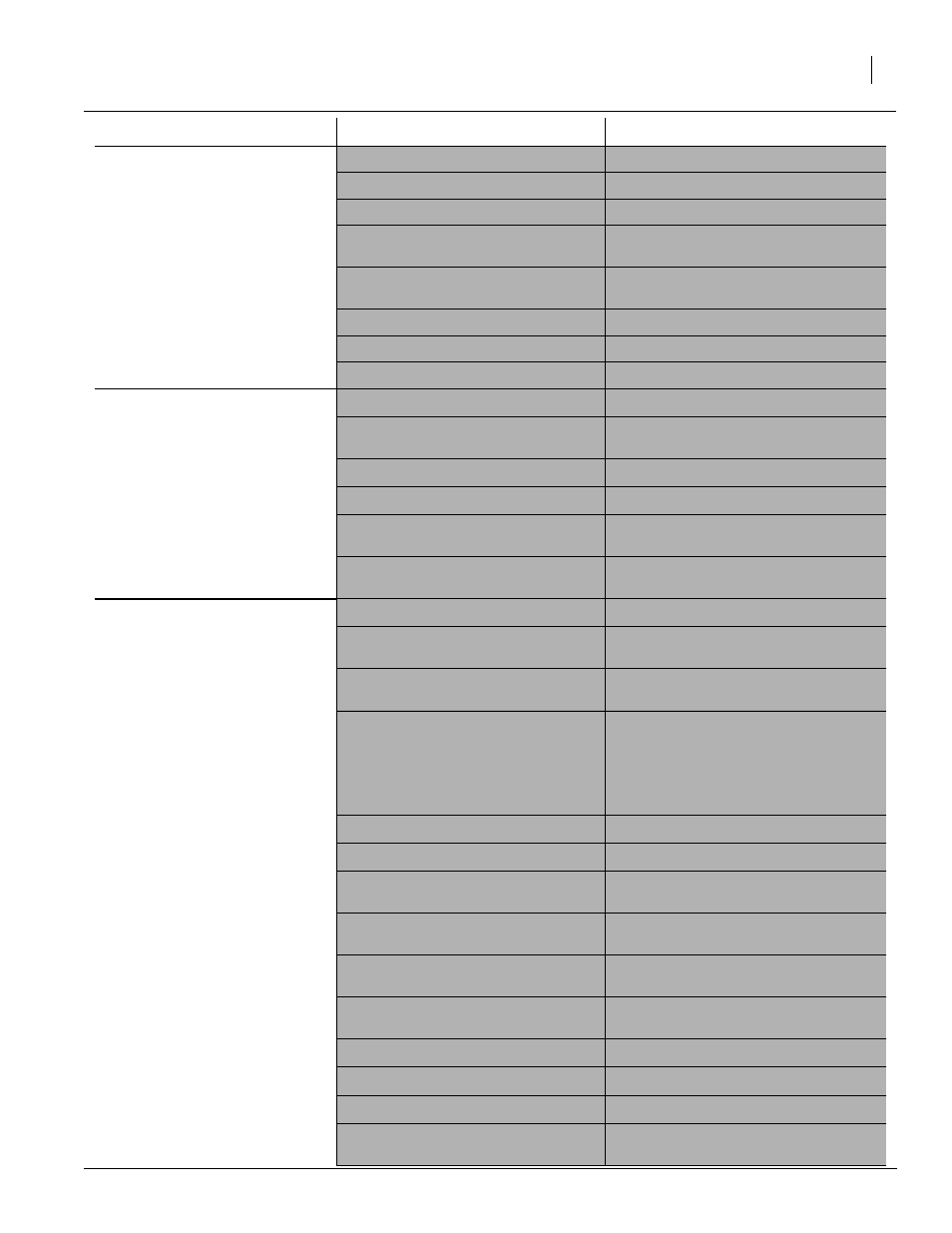

Troubleshooting

Excessive seed cracking

Excessive field speed.

Slow down.

Unclean seed.

Use clean seed.

Incorrect seed meter wheel.

Change seed meter wheel, page 48.

Incorrect seed size for seed meter

wheel.

Verify seed count on seed bag with seed

meter wheel.

Build up of seed treatment in seed

meter wheel pockets.

Clean seed meter wheel. Add more talc

lubricant.

Worn or damaged seed meter wheel.

Replace seed meter wheel.

Worn or damaged meter slide.

Replace meter slide, page 71.

Damaged, old or dry seed.

Use clean, new seed.

Drill boxes do not empty evenly

Meter(s) are shut off.

Open meter(s).

Opener seed tube plugged.

Lift up drill, expose bottom of seed tube

and clean out with wire.

Sliding seed tube plugged.

Clean out sliding seed tube.

Drive chains damaged or missing.

Replace drive chains.

Planting around fields vs. back-and-

forth.

Correct planting operation.

Rough field conditions may move

seed in the box.

Press wheel or openers plugging

Planting conditions too wet.

Wait until drier weather.

Coulters not set deep enough to cut

residue.

Check coulter adjustment.

Coulters set too deep, bring up

excess dirt and moisture.

Check coulter adjustment.

Drill not set to run level from front to

rear, carrying enough weight on

gauge wheels to prevent “nosing

over”, or set too low on rear caster

eyebolts allowing it to run “nose

high”.

Check Leveling Frame Front-to-Rear,

page 19.

Opener set too deep.

Opener spring force too high.

15 Series Openers press wheel spring

force too high.

15 Series Openers 1 x 12 press wheel

stagger adjustment not correct.

Correct press wheel stagger.

20 and 25 Series Openers press wheel

spring force too high.

20 and 25 Series Openers 1 x 12 press

wheel stagger adjustment not correct.

Correct press wheel stagger.

Backed up with drill in the ground

Clean out and check for damage.

Failed disk bearings

Replace disk bearings.

Disk blades worn.

Adjust or replace disk blades, page 13.

20 and 25 Series Opener side depth

wheels not adjusted correctly.

Problem

Cause

Solution