10 series & 20 series coulter adjustments – Great Plains 3N-4025P Operator Manual User Manual

Page 33

4/23/2010

196-286M

31

Adjustments

Second, the press wheels provide opener depth

control on 10 series openers (on 15, 20 and 25 se-

ries side wheels control depth).The higher the

press wheels run relative to the double disks, the

deeper seed will be placed. To maintain a consis-

tent depth, upward press-wheel movement is

restricted by an independently adjustable stop on

each opener. Refer to “Opener Seeding Depth,”

page 35, for information on how to make this

adjustment.

10 Series & 20 Series Coulter

Adjustments

The drill is assembled so that when the coulters

are at two inches deep, the seeding depth is about

one inch. This is a good baseline setting for most

seeding operations. As field conditions warrant,

you can change settings on the entire drill or indi-

vidual coulters. Unit mount 15 series are set equal

to opener depth.

To prevent uneven seeding depth and excess opener

wear, run coulters at least 1 inch below seeding

depth.

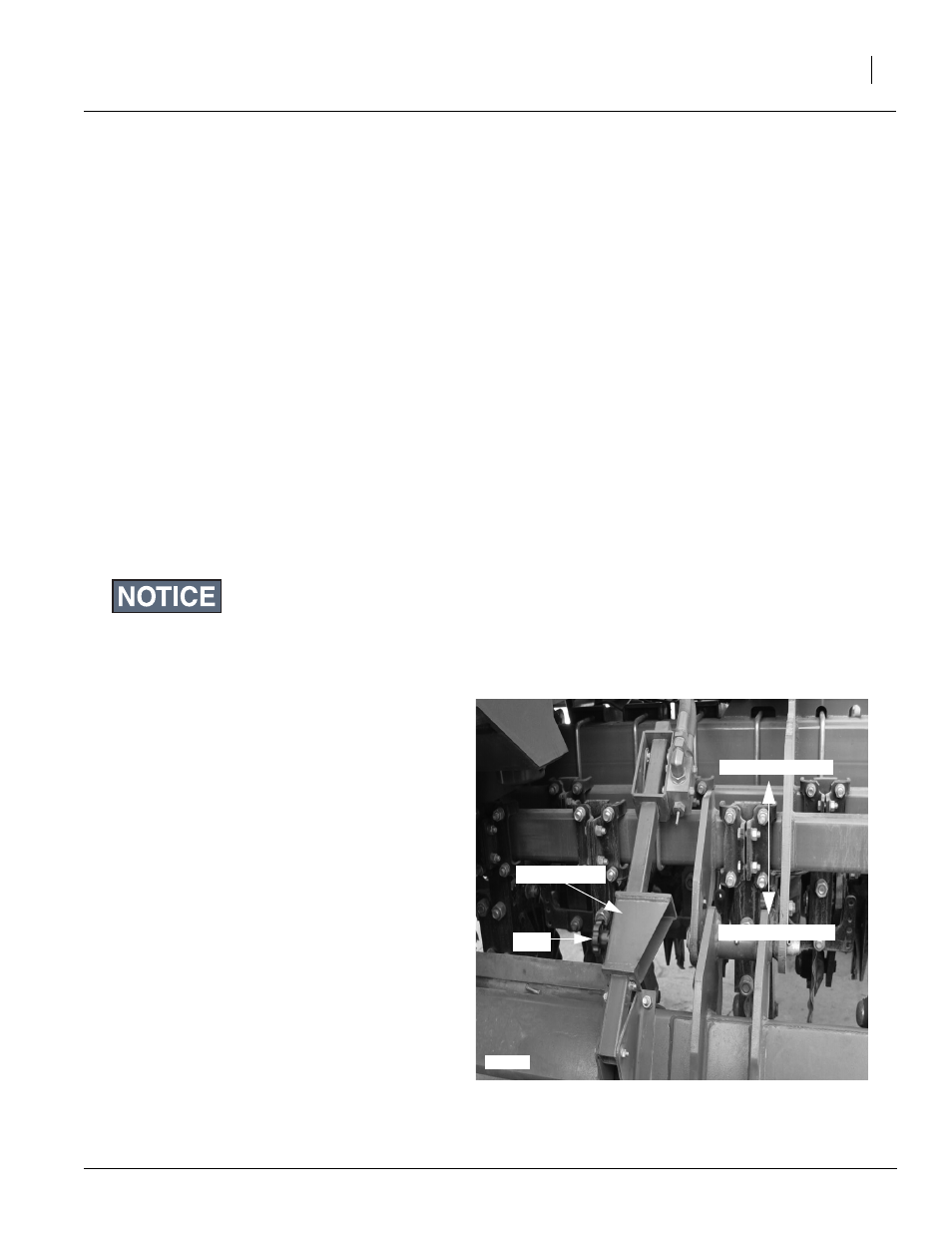

Hydraulic Depth Control

Refer to Figure 20

The field-lift cylinders are equipped with a hydrau-

lic valve that regulates coulter depth. Use the

valve to adjust coulter depth.

Loosen the bolt on the side of the depth stop and

slide the depth stop up to raise coulters or down to

lower coulters. Retighten bolt after setting the

depth stop.

Make depth adjustments with the implement

slightly raised. After adjusting the valve, raise and

lower the implement several times and recheck

coulter depth.

The depth stop regulates depth on all coulters. If

the ends of either box run higher or lower than the

center, the field-lift system may be out of phase or

have air in it, or the frame sections may not be lev-

el. Refer to “Rephasing Lift System,” page 24,

“Bleeding Lift Hydraulics,” page 17, or “Leveling

Frame Side-to-Side,” page 19.

Depth Stop

Bolt

Raise Coulters

Lower Coulters

20274

Figure 20

Depth Control Adjustment

Note: It is important that all of the tires remain

in contact with the ground to maintain level-

ness of machine from front to rear. Setting the

depth control too deep combined with high

opener spring force can cause the drill to tip

forward when planting, which may cause plug-

ging.

Running with the front tires floating or skimming on

the ground will cause uneven coulter depth and

may cause uneven seed depth.