Great Plains TCN5313 Operator Manual User Manual

Page 60

56

TCN5107-5313

Great Plains Manufacturing, Inc.

566-170M

03/17/2014

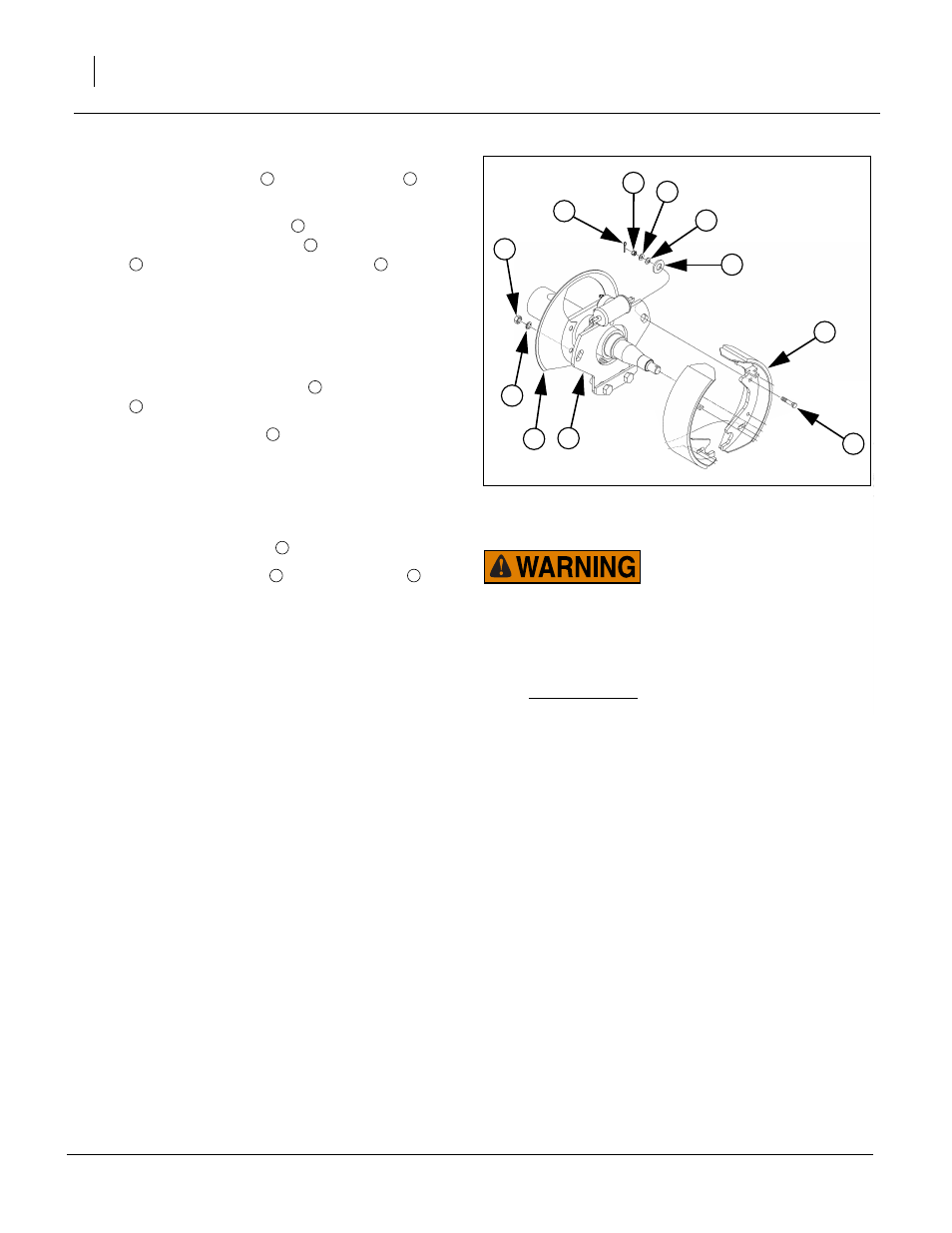

Refer to Figure 52

27. Remove five

1

⁄

2

-13 nuts

and lock washers

behind dust shield.

28. Pull backing plate assembly

far enough out on

spindle, away from dust cover

, to allow access to

nuts

on the two shoe hold down bolts

.

Note: If you prefer to perform a bench repair on the

brakes, and wish to avoid opening the hydraulic

system, remove the bolts holding the wheel cylin-

der. This allows complete removal of the backing

plate.

29. Remove hold down cotter pins

and castellated

nuts

.

30. Remove spring washers

.

Note the orientation of these washers. They must be

re-installed in the same relationship to each other,

and to the nut/washer, in order to provide correct

spring force.

31. Remove large flat washer

.

32. Remove hold down bolts

and brake shoes

.

33. Inspect brake shoes. Check that web is flat and at a

right angle to table. Check welds for cracks. Check

operating holes for wear and peening. If any defect

or damage is noted, replace shoes regardless of lin-

ing status.

34. Replace any shoes contaminated with oil.

35. If replacing one shoe set due to normal wear, Great

Plains recommends replacing all shoes on the

machine.

Braking Malfunction Hazard:

Always replace brake shoes in pairs - both shoes on the same

drum. Replacing only one shoe of each set can lead to reduced

braking performance, or loss of braking, with the risk of an

accident resulting in death, serious injury or property damage.

Note: Cannot Re-Line:

Original and replacement brake shoes supplied or

recommended by Great Plains have bonded lin-

ings. They cannot be re-lined. Replace entire

shoes, in pairs.

Figure 52

Brake Shoe Removal

29642

1

2

4

3

5

6

7

8

9

s

8

1

2

3

4

5

6

7

5

8

9

6

s