Brake drum and liner maintenance – Great Plains TCN5313 Operator Manual User Manual

Page 55

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

51

03/17/2014

566-170M

Clean filters seasonally; more often in dusty conditions.

1.

Move the machine to a sheltered area, to prevent

unfiltered dust from entering the opened air system.

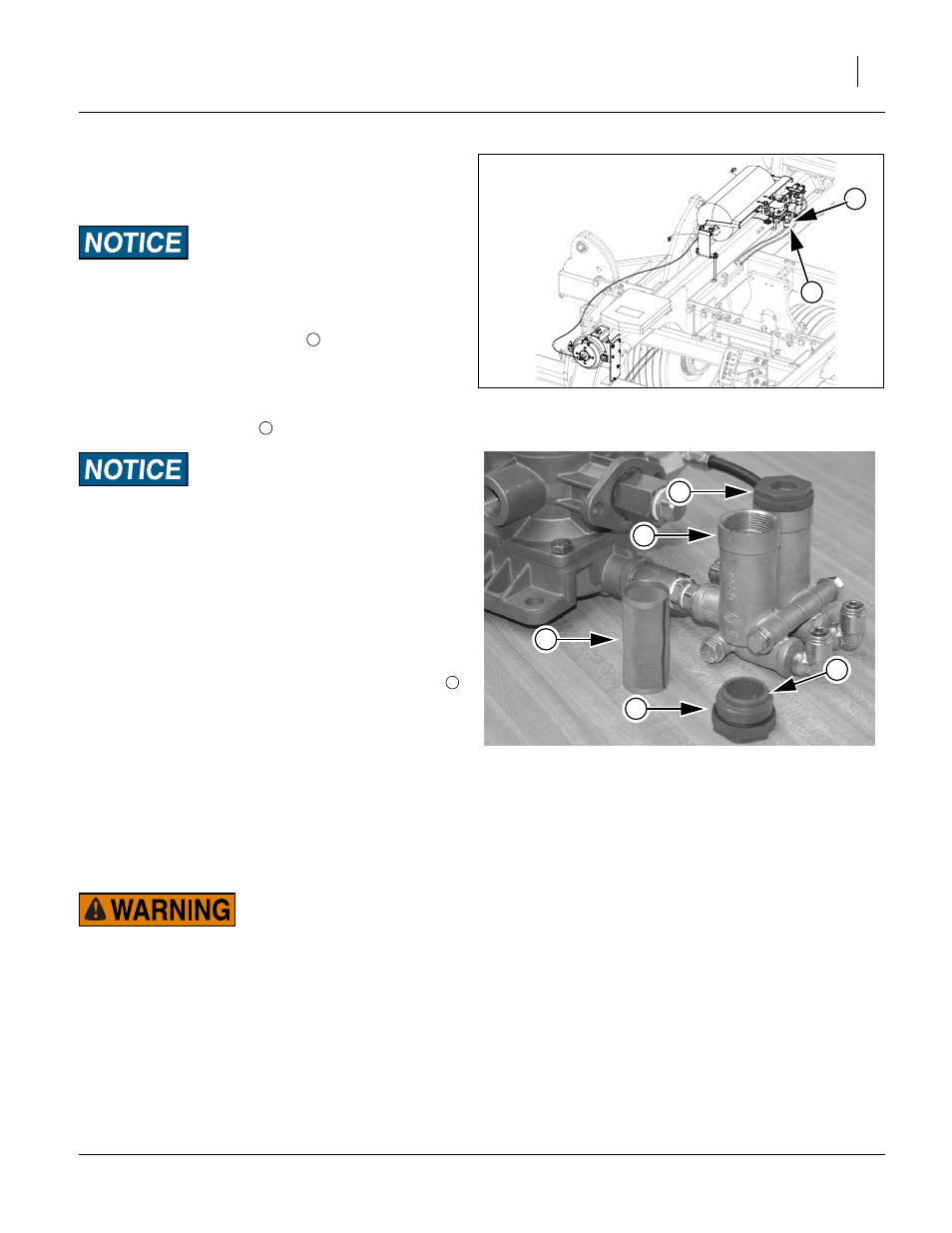

Do not remove the valve system to clean filters. Caps must be

on bottom of filter when removed.

2.

Use a 33mm (1

9

⁄

32

in) open-end or adjustable wrench

to loosen both red filter caps

.

Note: There is generally insufficient clearance between

the filters for a socket or box-end wrench.

3.

Carefully remove the cap from one filter. Be ready to

catch the filter screen

when it falls free.

Handle the filter screen element very gently. Great Plains

offers only complete replacement filters, and not screen ele-

ments.

Note: The inside diameter of the screen is the inlet side.

The screen is entirely welded stainless steel.

4.

Using gentle compressed air, or a soft brush and

compatible cleaning fluid, remove debris from the

screen. Dry thoroughly.

5.

The cap is a debris sump. Clean it with air, or water

and mild detergent. Clean and inspect the O-ring

.

Dry the cap if wetted.

6.

Center the filter screen on the cap. Carefully re-

insert in filter body. Screw cap in, checking for mis-

alignment or binding of filter element. Tighten cap

gently with wrench.

7.

Repeat step 3 through step 6 for the other filter.

Brake Drum and Liner Maintenance

Great Plains recommends having brakes serviced by

trained and fully equipped brake technicians.

Non-Asbestos Fibers Hazard:

Most recently manufactured brake linings are asbestos-free.

However, non-asbestos brake linings may contain one or more

of a variety of ingredients, including glass fibers, mineral

wool, aramid fibers, ceramic fibers and silica that can be

health risks if inhaled.

Scientists disagree on the extent of the risks from exposure to

these substances. Exposure to silica dust can cause silicosis, a

non-cancerous lung disease. Silicosis gradually reduces lung

capacity and efficiency and can result in serious breathing dif-

ficulty. Some scientists believe other types of non-asbestos

fibers, when inhaled, can cause similar diseases of the lung.

Silica dust and ceramic fiber dust are known to the State of

California to cause lung cancer. U.S. and international agen-

cies have also determined that dust from mineral wool,

ceramic fibers and silica are potential causes of cancer.

For silica, OSHA has set a maximum allowable level of

exposure of 0.1 mg/m

3

, 8-hour time-weighted average.

Some manufacturers of non-asbestos brake linings rec-

ommend that exposures to other ingredients be kept

below 1.0 f/cc, 8-hour time-weighted average.

Scientists disagree, however, to what extent adherence

to these maximum allowable exposure levels will elimi-

nate the risk of disease that can result from inhaling non-

asbestos dust.

The following procedures for servicing brakes are recom-

mended to reduce exposure to non-asbestos fiber dust,

Figure 46

Brake Master Cylinder

41998

2

3

3

4

Figure 47

Air System Filter Screen

29592

3

4

5

3

2

5