Brake shoe replacement – Great Plains TCN5313 Operator Manual User Manual

Page 57

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

53

03/17/2014

566-170M

Brake Shoe Replacement

Check brakes for wear, contamination and damage sea-

sonally or every 9600 km (6000 miles).

1.

Prior to commencing work, review the safety informa-

tion on page 51. Have necessary safety equipment

and tools on hand. Make sure workers understand

the hazards and how to avoid them.

2.

Review the entire procedure. Great Plains suggests

performing a complete operation on one wheel, or

one pair of wheels, at a time, so that there are fully-

assembled wheels to use as an assembly reference.

3.

Spot the machine on a level surface. Unfold the

machine.

4.

Block the wing and rear machine tires to prevent

movement. Do not set the machine’s own parking

brakes, as the drums cannot be removed with the

brakes.

If left hitched, put the tractor transmission in Park,

release tractor service and parking breaks, and dis-

connect the trailer brakes at the hitch. Set tractor

parking brake only after trailer brake disconnection

If unhitched, release air brakes by opening dump

valve

. Pull down on cap to release. Push up.

6.

Jack up and support one or both machine transport

axles.

7.

Be wearing and using recommended safety equip-

ment for the remainder of these procedures.

8.

Spin the wheels, checking for evidence of excess run-

out at the braking surface of the drums.

9.

Remove wheels. If you have more than one wheel

removed at a time, mark on them where they came

from (L/R and inside/outside), as the tire tread pattern

is direct.

Possible Asbestos Hazard:

If you are unable to confirm that you are removing and install-

ing Great Plains approved parts, you may have linings that

contain asbestos. Some aftermarket brake shoes may contain

asbestos, and require strict, complex and costly safety proce-

dures not covered in this manual.

If shoe replacement is indicated, use only parts supplied or

recommended by Great Plains. The original brake linings, and

Great Plains supplied or approved linings contain no asbestos.

Unapproved parts may also appear to fit, but will not function

correctly.

Note: Inspection of the brakes may also reveal a need to

refinish drums and/or replace other brake parts. Al-

though not strictly part of brake maintenance, you

may need to repack bearings (generally the outer),

and it may be necessary to replace a worn or dam-

aged inner seal (and repack the inner bearing).

1

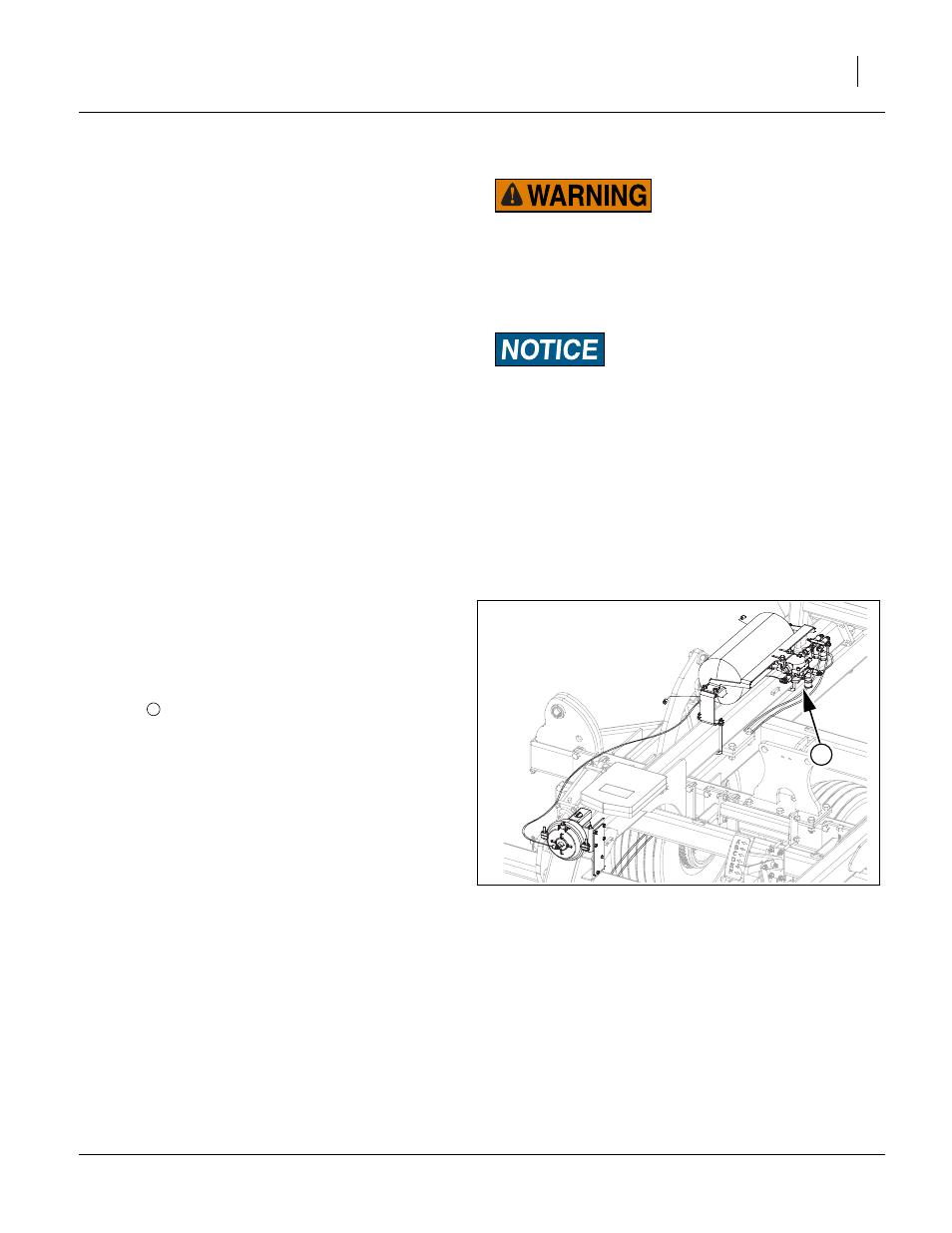

Figure 48

Air Brake Dump Valve

41998

1