Lubrication and scheduled maintenance, Wheel bearing hub, Brake maintenance (option) – Great Plains TCN5313 Operator Manual User Manual

Page 52: Brake line charge and bleed, Urbo-chisel as indicated under “ lubrica

48

TCN5107-5313

Great Plains Manufacturing, Inc.

566-170M

03/17/2014

Lubrication and Scheduled Maintenance

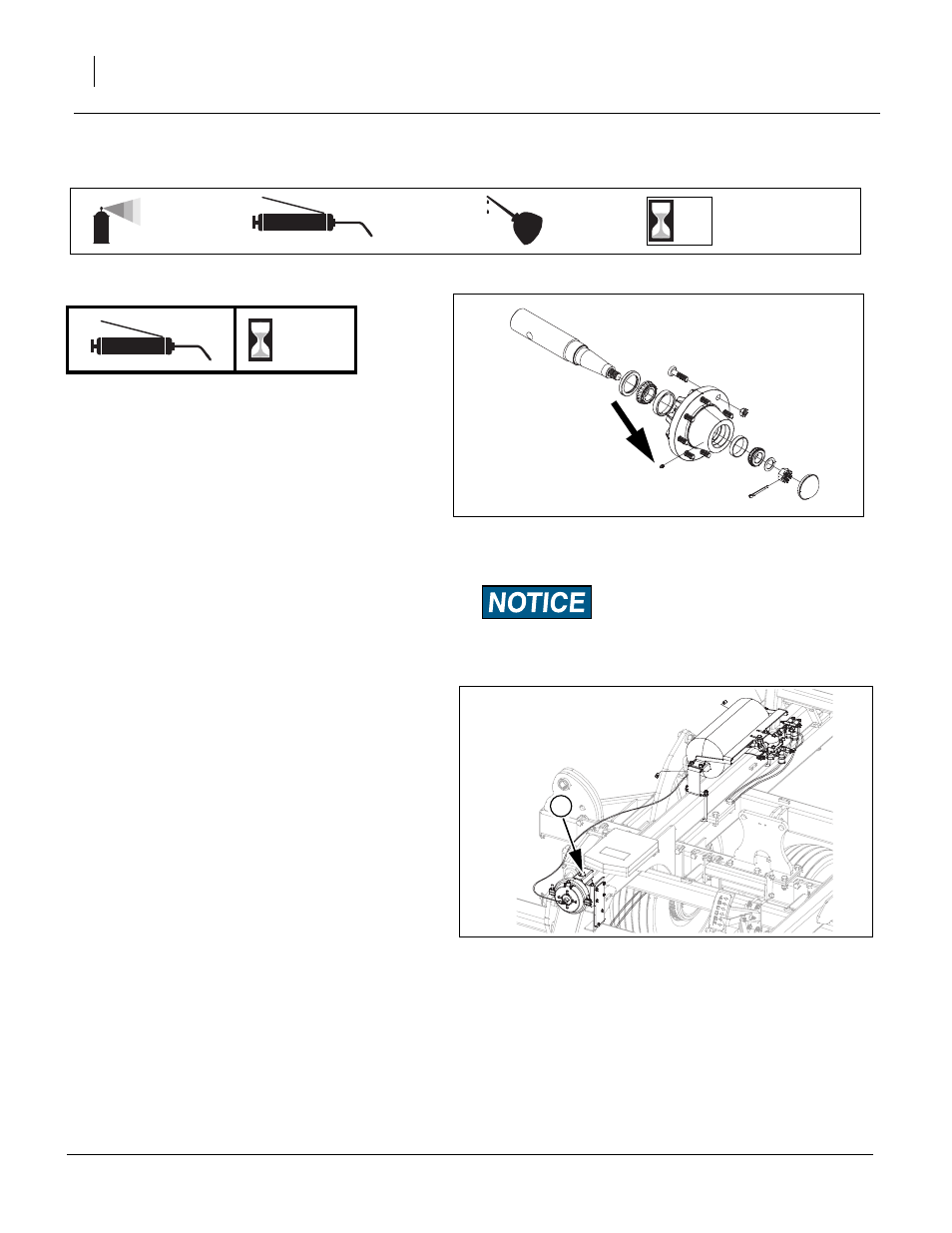

Wheel Bearing Hub

1 zerk on each hub;

4 total

Type of Lubrication: Grease

Quantity: Sparingly, Do Not Over Grease, may cause

damage to seal.

Repack wheel bearings annually or every 2500 acres.

Brake Maintenance (Option)

Brakes are self-adjusting, but there are several mainte-

nance items:

page 48 - Brake Line Charge and Bleed

page 50 - Air Brake Filter Cleaning

page 51 - Brake Drum and Liner Maintenance

Brake Line Charge and Bleed

Prior to first use, and after replacing any components

that carry brake fluid, and during periodic flushing of the

brake system, the brake lines need to be bled.

1.

Spot the machine on a level surface at a safe dis-

tance from any ignition sources (brake fluid is flam-

mable). Unless conditions are dry and calm, use a

sheltered area, to keep moisture and contaminants

out of brake fluid. Leave the tractor hitched to pro-

vide braking action to systems.

2.

Unfold the machine and block the machine tires to

prevent movement. Do not set the machine’s own

parking brakes, as this restricts cylinder movement.

3.

Put tractor in Park. Do not set tractor parking brake if

it also operates trailer brakes.

50

50

Multipurpose

spray lube

Multipurpose

grease lube

Multipurpose

oil lube

Intervals (service hours)

at which lubrication is

required

41991

Figure 39

Brake Master Cylinder

41998

1

Never re-use brake fluid. It is hygroscopic (formulated to

absorb water, which can damage system components if not

removed). Dispose of brake fluid per supplier instructions.