Great Plains TCN5313 Operator Manual User Manual

Page 58

54

TCN5107-5313

Great Plains Manufacturing, Inc.

566-170M

03/17/2014

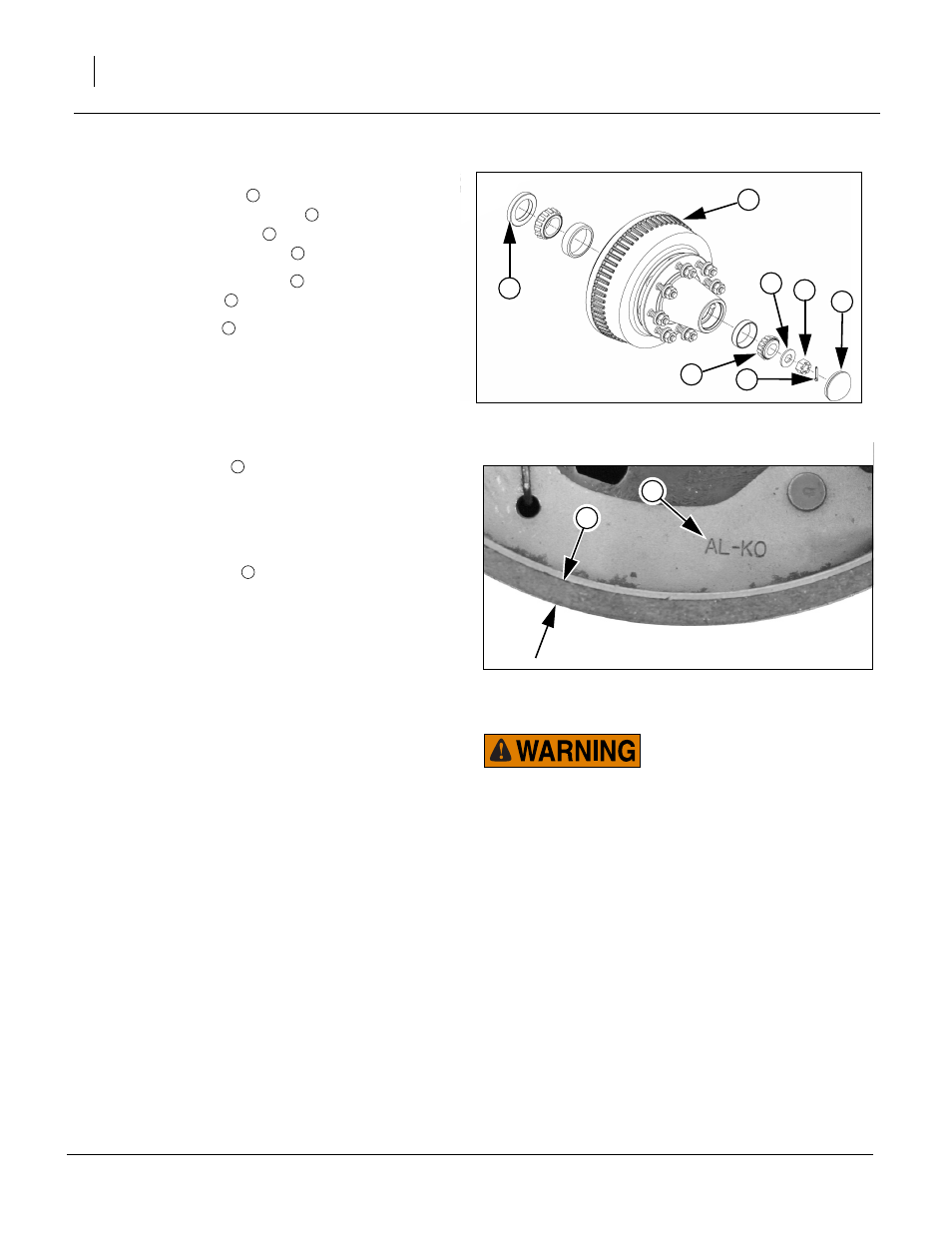

Refer to Figure 49

10. Remove hub/drum assemblies:

Remove the dust cap

.

Remove the spindle cotter pin

.

Remove the spindle nut

.

Remove the spindle washer

.

11. Carefully pull hub and drum

assembly from spin-

dle. Outer bearing

may fall loose.

12. Inspect inner seal

, bearings, hub and drum for

wear and damage - for drum, see “Brake Drum

Maintenance” on page 58).

13. Keep inner and outer bearing components sepa-

rated. They are different parts.

Refer to Figure 50

14. Inspect brake shoe

origin. See Warning at right.

Great Plains supplied shoes are stamped “AL-KO”

on the web face and have bonded linings.

15. Clean brake dust from assembled parts, and from

individual parts as removed.

16. Inspect brake linings

. Check for 1.6mm (

1

⁄

16

in)

minimum thickness (exclude thickness of shoe pad),

and absence of grease, contamination, deep scores,

chipping, or excessive heat fractures. Hairline heat

fissures are not unusual and do not require shoe

replacement.

17. Inspect brake shoe retaining and operating hard-

ware. Check for wear or damage to holes, pins and

springs. Check for weak springs. Springs must com-

pletely retract shoes when brakes are released.

Note: Sound practice is to replace springs when replac-

ing brake shoes.

18. Check wheel cylinder for evidence of leaks.

If no parts need replacing, skip to step 49.

Figure 49

Hub Removal

29642

2

3

4

5

6

7

8

2

3

4

5

6

7

8

Part Failure Hazard:

Do not substitute parts. Incorrect or substandard parts can

cause brake malfunction or failure, resulting in death, serious

injury or property damage. Always re-assemble brakes with

either the removed parts (if serviceable) or Great Plains parts

as specified in the Parts Manual (550-466P).

Figure 50

Brake Shoe ID & Thickness

29643

8

9

8

9