Material clean-out, Tank clean-out – Great Plains NP4000 40-foot Operator Manual User Manual

Page 83

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

79

2012-03-28

407-776M

Material Clean-Out

With proper attention to maintenance, end of day

clean-out, end of season clean-out and winterization,

you can substantially increase the life and reliability of

your fertilizer system. Protect the pump, clean the tanks,

strainers, lines and nozzles, and you can avoid costly

and time-consuming repairs at the next season.

Fertilizers are usually highly corrosive to metals other

than stainless steel. Suspension fertilizers can clog

system components in storage.

1.

Flush entire system with clean water.

2.

Remove end caps from booms and flush booms out

with water. Drain and replace end caps.

3.

Remove strainer and drain it out. Drain all lines and

tanks completely to prevent freezing damage.

4.

Flush pump per pump supplier manual. Fill pump

with RV antifreeze and cap off.

5.

Wash all spilled fertilizer off the applicator.

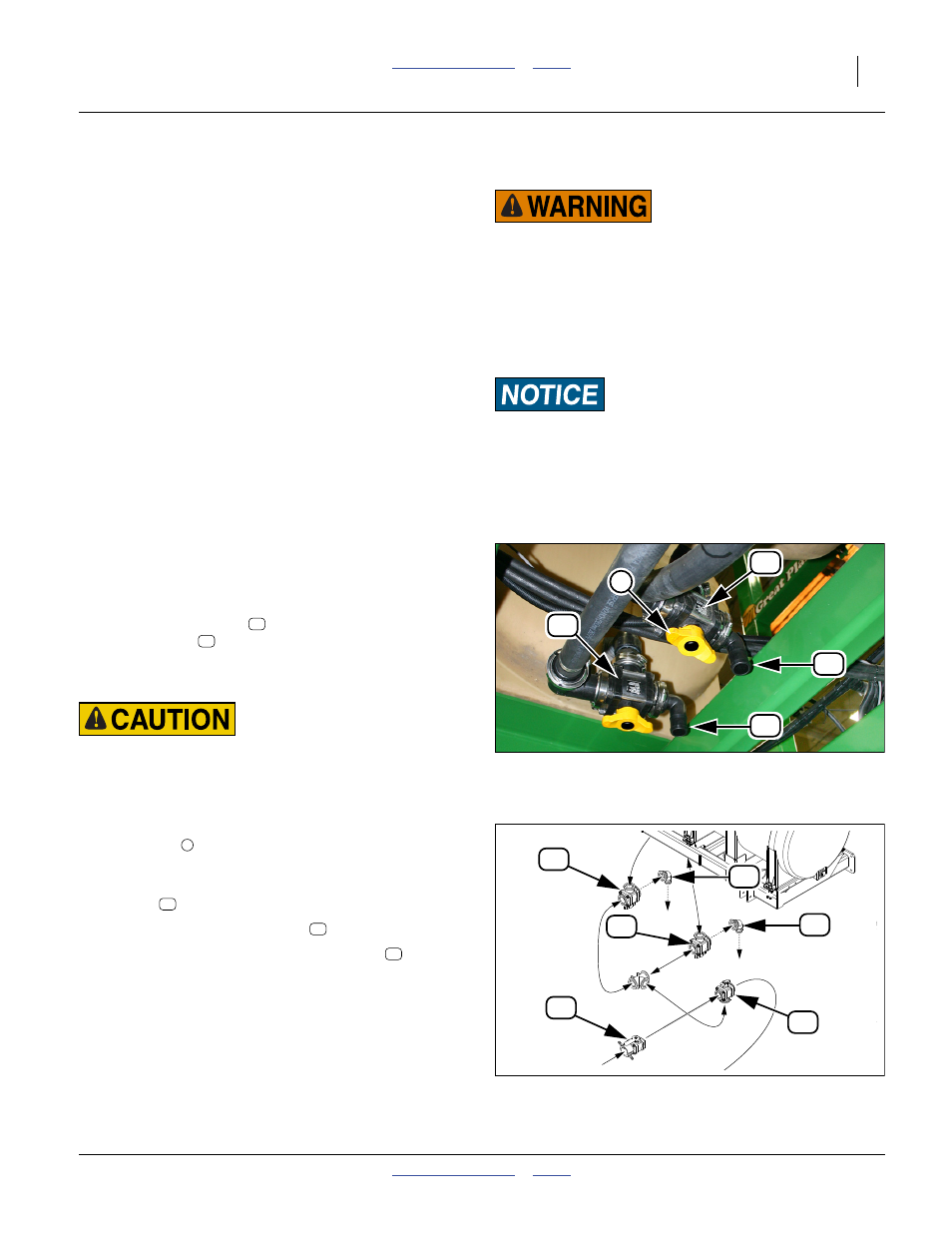

Tank Clean-Out

Refer to Figure 55 - which depicts the discharge valves open to

the selector valve (not shown)

For bulk recovery of unused material, or for rinsing out

tanks, dump line elbows

are provided at the tank

discharge valves

.

For connection of collection hoses, the elbows require a

hose with 1

1

⁄

2

inch inside diameter.

Possible Chemical Hazard:

Operate the valves from above. Wear chemical gloves. Inspect

the valves from below only when flow is shut off. Wear eye

protection when working under the tanks.

The valve operating handles have the word “FLOW” and

a raised arrow

that point in the open direction of flow.

This provides tactile indication of handle orientation.

1.

Connect any drain or collection hoses to the

elbows

.

2.

Check that the selector valve

is closed.

3.

Rotate one or both tank discharge valve

operating handles to the elbows.

4.

As desired, rinse out tanks from open lids.

Note: Parts of the tank plumbing system (to the selector

valve) are below the elbows. These lines must be

disconnected to completely drain them.

Possible Chemical Hazard:

Wear proper protective equipment as required by chemical

manufacturer. Avoid prolonged breathing of chemical fumes.

Wear respirator as required by chemical manufacturer. Some

chemicals will cause serious burns, lung damage, and death.

Avoid contact with skin or eyes. Seek medical assistance

immediately if accident occurs. Know what to do in case of an

accident.

Equipment Damage Risk:

Do not leave fertilizer or fertilizer residue in pump. Do not

allow air to enter pump. Even for short periods of storage, the

entrance of air into the pump causes RAPID and SEVERE

CORROSION.

Figure 55

Tank Discharge Valves

32017

14

14

13

13

1

14

13

Figure 56

Tank System Valves

31955

13

13

14

14

15

17

1

14

15

13