Shift 2-point hitch, Caster and gauge wheel considerations, Reset and disable pumps – Great Plains NP4000 40-foot Operator Manual User Manual

Page 121

Great Plains Manufacturing, Inc.

Appendix C - Accessory Installation

117

2012-03-28

407-776M

Shift 2-Point Hitch

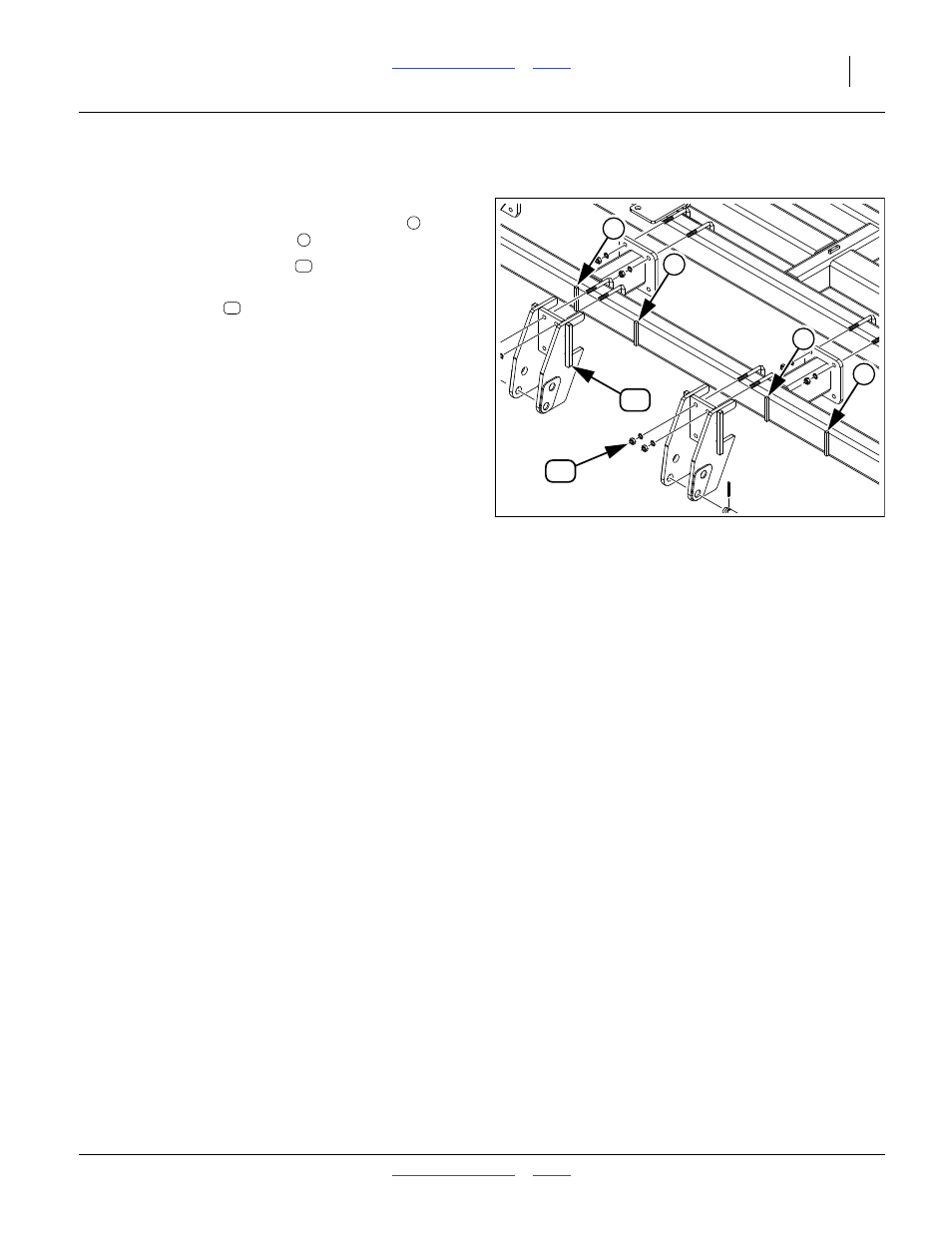

Refer to Figure 77

The front tool bar of the forward sub-frame has stop keys

for the standard (pre-emergence) hitch position

and

for the side dress hitch position

.

39. Loosen or remove the nuts

at all four hitch

U-bolts.

40. Move each hitch

to align the left edge of the bolt

plate with the left stop keys on the frame.

41. Tighten nuts to

3

⁄

4

-10 Grade 5 torque specification.

Caster and Gauge Wheel Considerations

42. As needed, adjust the angle of casters to keep tires

between rows of post-emergence crops. See

page 62.

Note: Keep caster angles symmetrical. Great Plains

does not recommend angling both casters left to

mimic the hitch shift, as this has negligible benefit

afield. A both-left configuration could cause

problems when raised, as wheels would be to left of

machine center of gravity (particularly with optional

weights). This could result in tipping right in turns

and unbalanced weight transfer.

43. As needed, shift the mount position of wing gauge

wheels to keep tires between rows of

post-emergence crops.

Note: When relocation gauge wheel mounts, position

them as far out on the wing as the tire track

requirements allow.

Reset and Disable Pumps

44. With side dress installed, both the row count and

swath of the implement change. Configure the

ground drive pump or controller console for 13 rows

and the wider swath. “Fertilizer Rate” on page 64.

45. Take steps to prevent the rear boom pump from

operating. Remove the contact wheel or a chain from

a ground drive. Leave the hydraulics disconnected

for a hydraulic pump.

Figure 77

Hitch Shift

31844

60

2

3

2

3

72

2

3

72

60