Ground drive: set pump drive range, Ground drive: set pump rate dial – Great Plains NP4000 40-foot Operator Manual User Manual

Page 76

72

NP4000

Great Plains Manufacturing, Inc.

407-776M

2012-03-28

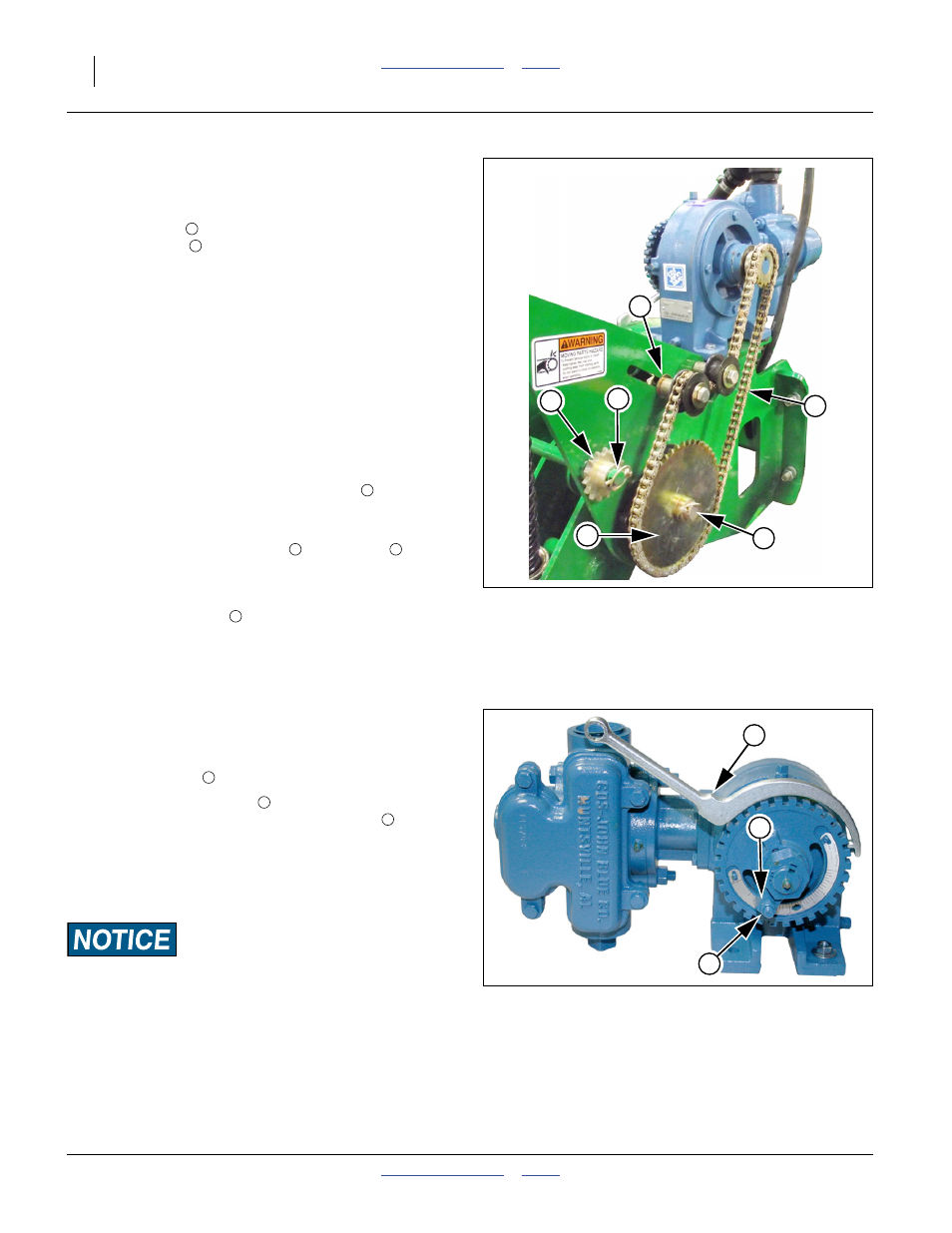

Ground Drive: Set Pump Drive Range

Refer to Figure 52

Two Driving sprockets are provided for the pump:

Low Range: 15T

High Range: 47T

The choice of Driving sprocket depends on the

application rate desired. The pump adjuster dial (see

Figure 53

) must be in the range 2-10 for consistent pump

rate.

Use the rate chart on page 68 to determine which Range

to use for the rate desired.

For implements with optional variable rate capability,

choose the sprocket which, at dial setting 10, provides a

rate higher than the maximum you intend to use. If Low

range suffices, use it for reduced pump wear.

To change Driving sprocket:

1.

Loosen the bolt securing the rear idler

. Slide the

idler forward. Lift the chain off the lower Driving

sprocket.

2.

Remove pins at the storage

and Driving

shafts.

3.

Exchange sprockets. Re-pin.

4.

Re-engage idler for slack of

3

⁄

8

in (9mm) in the

longest chain span

.

Ground Drive: Set Pump Rate Dial

Refer to Figure 53

Consult the 12-M-43 CDS-John Blue NGP Pump Parts

and Instructional manual for complete details on pump

operation and maintenance.

1.

Loosen the nut

at the setting pointer.

2.

Use the setting wrench

to rotate the dial until the

desired pump setting is under the pointer

.

Note: Settings below 2 are not recommended.

If presently using High range, switch to Low range

and use the dial setting for your rate in Low range.

3.

Tighten the nut.

Material Loss/Equipment Damage Risks:

Operate only with material loaded, or disconnect chain or

remove sprocket if not intending to apply material. Ground

drive wheel and chain system operate whenever the implement

is lowered and in motion. The pump must not be run dry.

Figure 52

Pump Range Sprockets

31656

5

3

4

1

2

6

1

2

3

4

5

6

Figure 53

Adjuster for NGP-7055-K Pump

31320

8

7

9

7

8

9