Connect coulter tubing – Great Plains NP4000 40-foot Operator Manual User Manual

Page 120

116

NP4000

Great Plains Manufacturing, Inc.

407-776M

2012-03-28

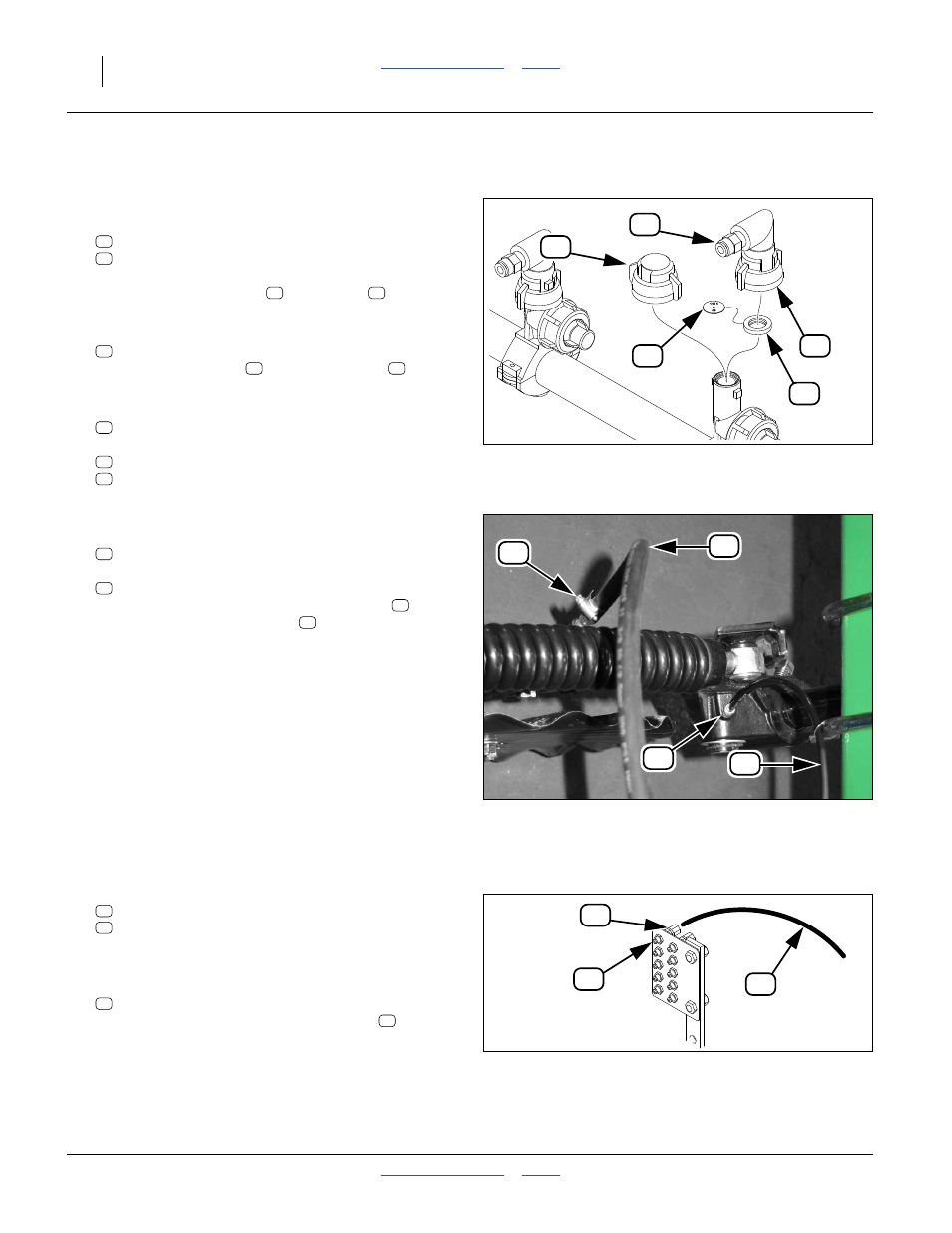

Connect Coulter Tubing

Refer to Figure 74

32. At the left end of the front boom, remove one cap

and gasket from the boom clamp:

832-042C NOZZLE SHUT OFF CAP W/ GASKET

CP18999-EPR ORIFICE SEAT STYLE GASKET

If a nozzle was removed at step 20 on page 114,

relocate the shut-off cap

and gasket

to the

open rear row boom clamp.

33. Select one new or saved:

CP18999-EPR ORIFICE SEAT STYLE GASKET

Install an orifice plate

inside the gasket

.

34. At the front left boom clamp, install one new or saved

nozzle set:

407-373S NOZZLE ASSEMBLY - 3/8 HOSE

which includes:

830-071C AD 1/4MNPT X 3/8HB POLYPROP

832-051C NOZZLE CAP QUICK X 90X1/4 FNPT

Refer to Figure 75 and Figure 74

35. Select one new or saved:

990-080R HOSE 3/8 ID 150PSI EPDM

and two:

800-390C CLAMP WRM DRV #6 SS (.38-.87)

Connect this hose from the nozzle adaptor

to the

coulter applicator attachment

.

Refer to Figure 76

36. Select one set new or saved:

800-130C GREASE ZERK STRAIGHT 1/8-27NPT

800-158C FTG TUBE,CONNECTOR 1/8 FNPT

Install these at an available hole in the front left wing

grease bank.

37. Select the new or saved:

990-109R TUBE NYLON 1/4OD X 062WL

Connect this from the grease bank fitting

to the

coulter pivot fitting (not shown). Secure with cable

ties between grease bank and coulter.

38. Pump grease until it emerges at the coulter pivot.

Figure 74

Fertilizer Nozzle Installation

29984

39

37

80

36

38

36

37

36

37

37

38

37

59

80

82

Figure 75

Drop Line, Grease Connections

32028

84

83

65

56

83

65

80

56

Figure 76

Grease Bank Fittings

32081

63

62

84

62

63

84

63