Chain maintenance, Chain slack, Row unit chain tension – Great Plains YP1220 Operator Manual User Manual

Page 64: Chain slack row unit chain tension

60

YP1220

Great Plains Manufacturing, Inc.

401-506M

03/14/2012

Chain Maintenance

Inspect and lubricate chains regularly. The slack of new

chains tends to increase during the first few hours of

operation due to seating.

Chain Slack

Check slack within the first 8 hours of operation and

tighten idlers as necessary.

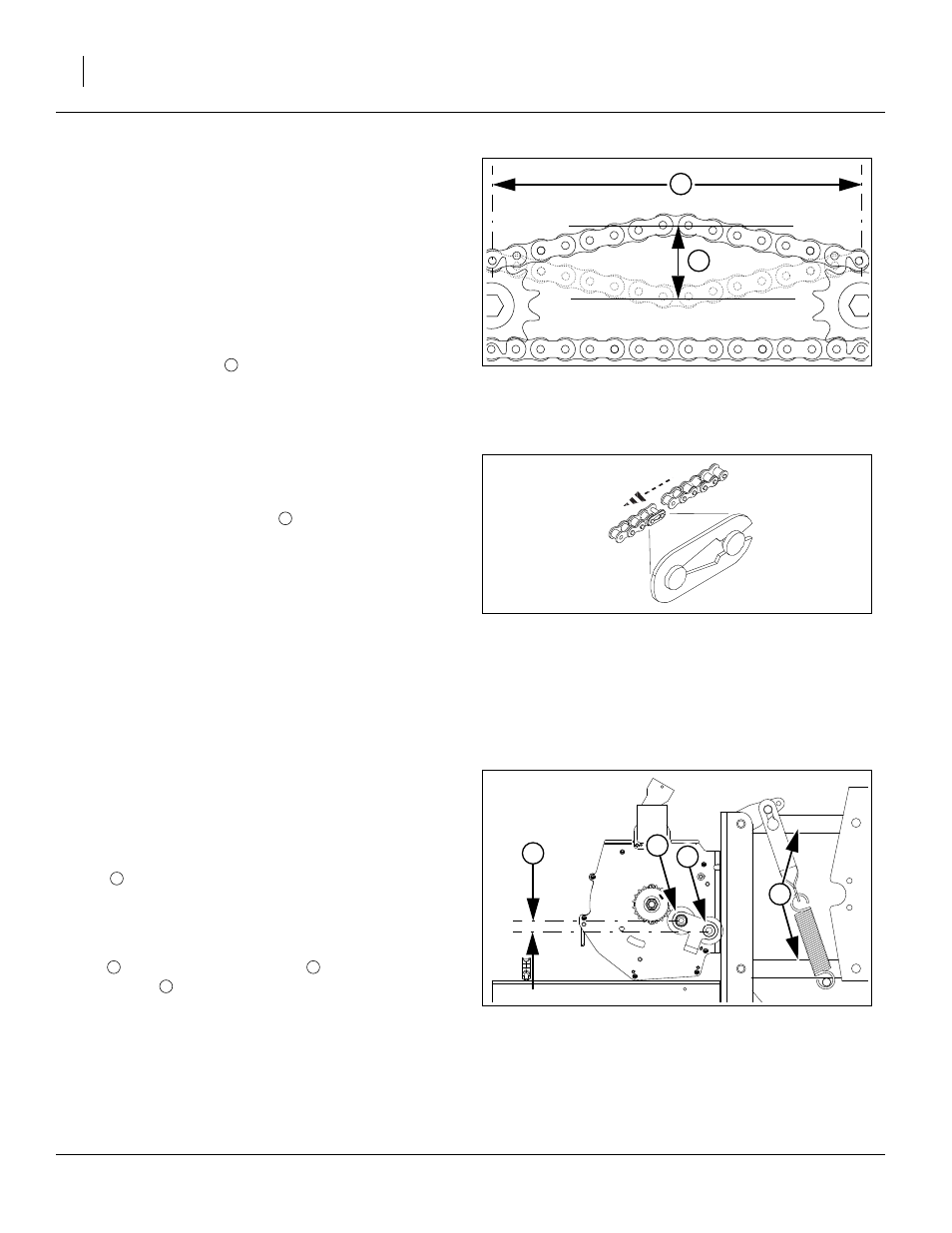

Refer to Figure 67, which, for clarity, greatly exaggerates

slack, and omits the idlers.

1.

Measure the span

for allowable slack:

Locate the longest span of each chain (usually the

span which does not run through the idlers).

2.

Determine the ideal slack:

Long chains (over 36in/91cm):

1

⁄

4

in per foot

Vertical short chains:

1

⁄

4

in per foot (2.1cm/m)

Horizontal short chains:

1

⁄

2

in per foot (4.2cm/m).

3.

Measure the current slack

:

Acting at a right angle to the chain span at the center

of the span, deflect the chain in both directions. The

slack is the distance of the movement.

4.

Adjust the idlers for ideal slack.

Whenever mounting a chain, make sure the clip at the

removable link is oriented to minimize snags.

Refer to Figure 68 (arrow shows chain direction)

Install clip with open end facing away from direction of

chain travel (shown by gray or striped arrows in chain

routing diagrams)

Row Unit Chain Tension

The seed meter drive has a spring-loaded idler which

requires no adjusting. However, chain stretch may make

it necessary to shorten the chain.

Refer to Figure 69

For best chain tension the recommended vertical dis-

tance

between chain idlers is:

minimum:

1

⁄

4

in (6.4mm)

maximum:

1

⁄

2

in (12.7mm)

This measurement should be taken with opener parallel

arms

. horizontal. The front idler

the rear idler

.

FigureSpacer:

Figure 67

Measuring Chain Slack

27264

2

1

FigureSpacer

Figure 68

Chain Clip Orientation

26482

Figure 69

20 Series Meter Chain

28024

1

3

2

4

2