Contact wheel drive – Great Plains YP1220 Operator Manual User Manual

Page 43

Great Plains Manufacturing, Inc.

Adjustments

39

03/14/2012

401-506M

Contact Wheel Drive

Refer to Figure 38

You can adjust the down pressure the contact wheel

exerts by adjusting the pressure on the spring.

Note: Do not adjust spring so tight that it will bottom out

when raised.

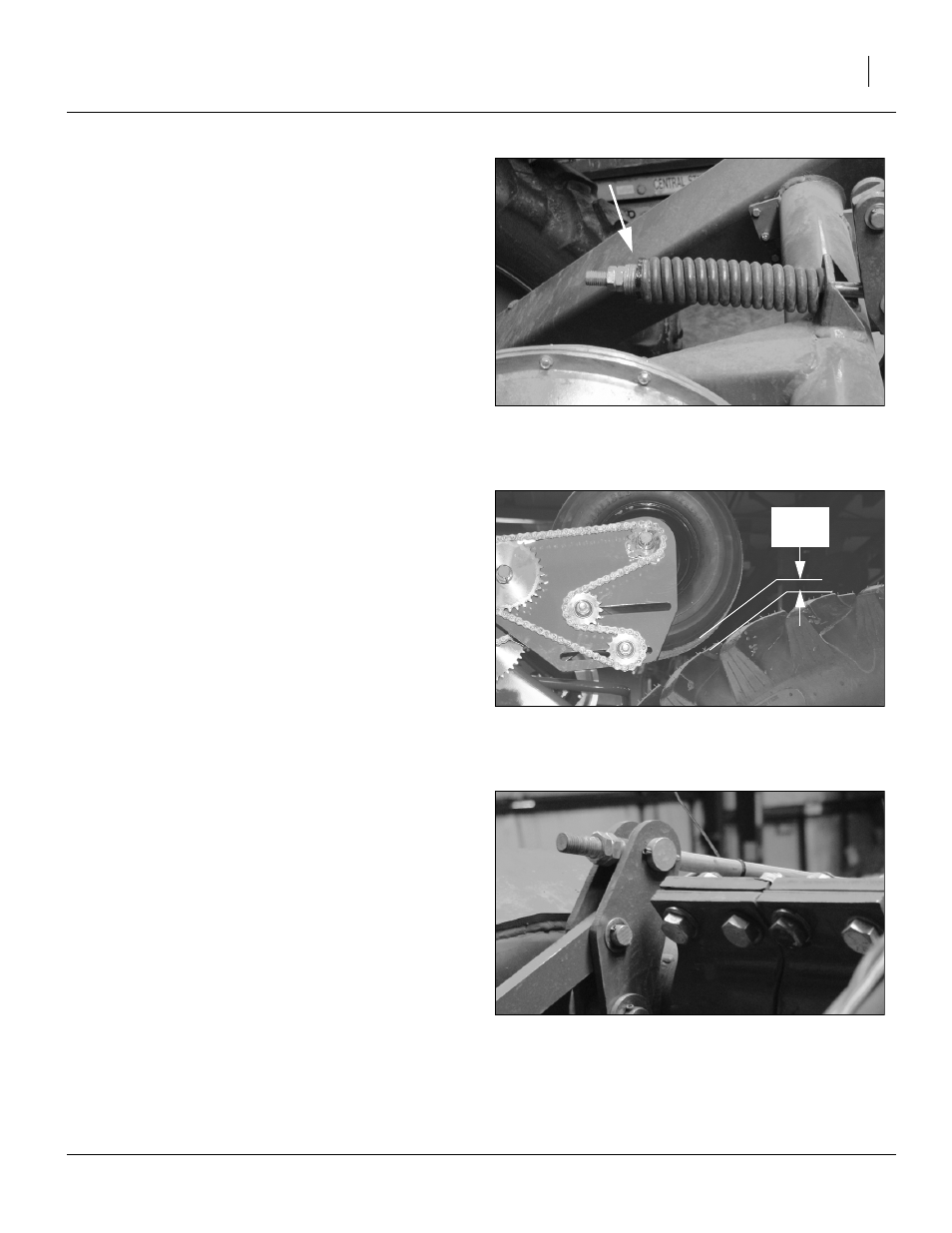

Refer to Figure 39

Before adjusting spring, raise planter and adjust wheel

travel to obtain 1

1

⁄

2

in clearance above the main tire.

Refer to Figure 40

You can adjust the amount of travel for the contact wheel

by loosing the jam nuts and lengthening or shortening

the threaded rod.

Note: This adjustment controls the timing of the seed

meter drive when raising and lowering the planter.

Increasing the gap between the tires causes seed

flow to start and stop with the planter at a lower

height. Decreasing the gap will cause seed flow to

start and stop at a higher position.

Note: Be sure to check for spring bottoming after making

this adjustment.

Figure 38

Down Pressure Spring

21973

Figure 39

Contact Drive Wheel

225003

1

1

⁄

2

in

Figure 40

Travel Adjustment

225003

- 1200 Parts Manual (210 pages)

- 706NT Material Rate (46 pages)

- 706NT Material Rate (50 pages)

- 2N-2410 Operator Manual (48 pages)

- 2N-2410 Operator Manual (56 pages)

- 12 Series Drills Assembly Instructions (6 pages)

- X-PresS 2006 Assembly Instructions (50 pages)

- TM500 Operator Manual (62 pages)

- 2010HDP Operator Manual (166 pages)

- YP1630F Material Rate (42 pages)

- YP2425 Operator Manual (162 pages)

- 3S-5000 Operator Manual (94 pages)

- 3PYP Operator Manual (188 pages)

- 3N-3010P Assembly Instructions (2 pages)

- 3N-3010 Assembly Instructions (9 pages)

- 3N-3010P Assembly Instructions (9 pages)

- PFH-15 Predelivery Manual (23 pages)

- PFH-15 Operator Manual (46 pages)

- PFH-15 Operator Manual (26 pages)

- P15126 Serial No 12724 (34 pages)

- DVN 8321 Operator Manual (38 pages)

- 3P500 Assembly Instructions (22 pages)

- 605NT Assembly Instructions (4 pages)

- 3P600 Assembly Instructions (12 pages)

- 605NT Assembly Instructions (8 pages)

- CPH-12 Assembly Instructions (3 pages)

- YP1625A-2420 24 Row 20-Inch Quick Start (6 pages)

- 8323 FCF Predelivery Manual (124 pages)

- P13937 (20 pages)

- 3323 DH Parts Manual (114 pages)

- YP3025-1820 25 Series 18 Row 20 Inch Quick Start (5 pages)

- CF500 Operator Manual (38 pages)

- PFH-15 Assembly Instructions (30 pages)

- 3500TM Parts Manual (106 pages)

- 1800TM Parts Manual (158 pages)

- YP2425A-2470 24 Row 70 cm Quick Start (5 pages)

- Simba Culti Press Operator Manual (38 pages)

- RU1999 Parts Manual (58 pages)

- 3N-30P Assembly Instructions (10 pages)

- 2510HDP Operator Manual (180 pages)

- YP1220 Parts Manual (136 pages)

- 3P500 Material Rate (68 pages)

- YP2425-3620 36 Row 20 Inch Quick Start (5 pages)

- 706NT Operator Manual (22 pages)

- 706NT Operator Manual (53 pages)