Electric clutch lockup, Row-unit operation – Great Plains YP1220 Operator Manual User Manual

Page 35

Great Plains Manufacturing, Inc.

Operating Instructions

31

03/14/2012

401-506M

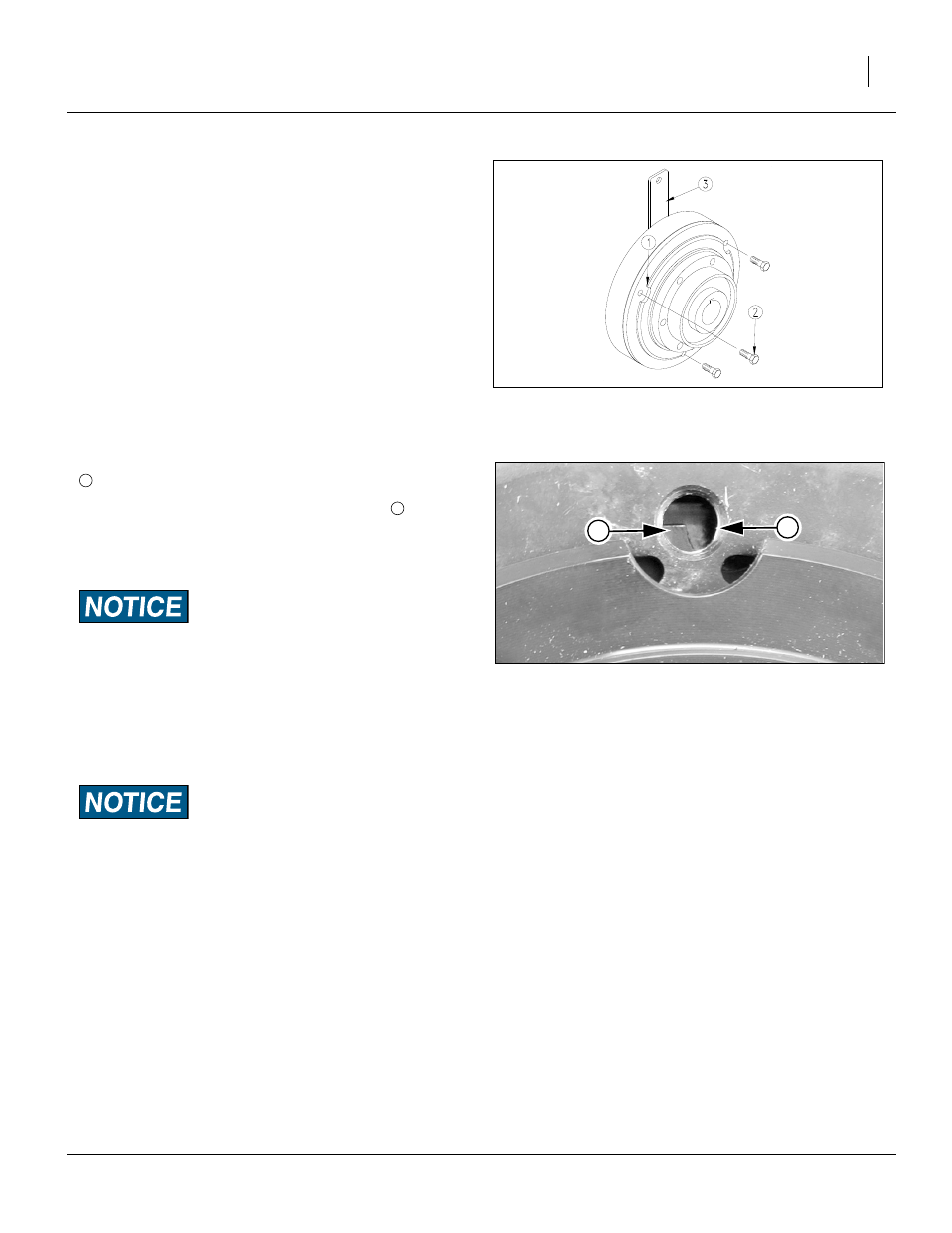

Electric Clutch Lockup

Refer to Figure 32

In case of electric clutch failure, electric clutches can be

bolted together.

1.

Align cutouts at bolt holes

➀

.

2.

Insert M8-1.25x14mm long metric bolts

➁

.

Note: Use only 14mm length bolts as provided or ma-

chine damage will occur. Longer bolts will damage

the clutch. Shorter bolts may not effect a lock-up.

3.

Unbolt field coil housing and make sure it is allowed

to move freely.

If you observe half the hole obstructed by a metal disc

, you are not at a cutout.

If the entire hole is obstructed by a metal disc

, you are

not at a cutout.

When at a cutout, the bolt will screw in with minimal

resistance until the bolt head reaches the clutch face.

Machine Damage Risk:

When lubricating the planter, do not allow lubricant to enter

the clutch, or clutch slippage will result.

Row-Unit Operation

Machine Damage Risk:

IMPORTANT! Do not back up with row-units in the ground,

because this will cause severe damage and row-unit plugging.

For information on row-unit adjustments, see “20 Series

Row-Unit Adjustments” on page 43. For more informa-

tion on troubleshooting row-unit problems, see “Trouble-

shooting” on page 50.

Figure 32

Electric Clutch Lockup

22906

Figure 33

Clutch Plate Nearly at Cutout

26168

1

4

4

4